Connecting structure of vehicle cabin longitudinal beam and front wall cross beam

A technology for connecting structures and nacelles, which is applied in the connection between superstructure sub-assemblies, superstructures, vehicle components, etc., can solve the problems of low manufacturing precision, large welding influence area, and high welding process requirements, and eliminate manufacturing errors. , Improve manufacturing accuracy, novel and unique effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and functions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

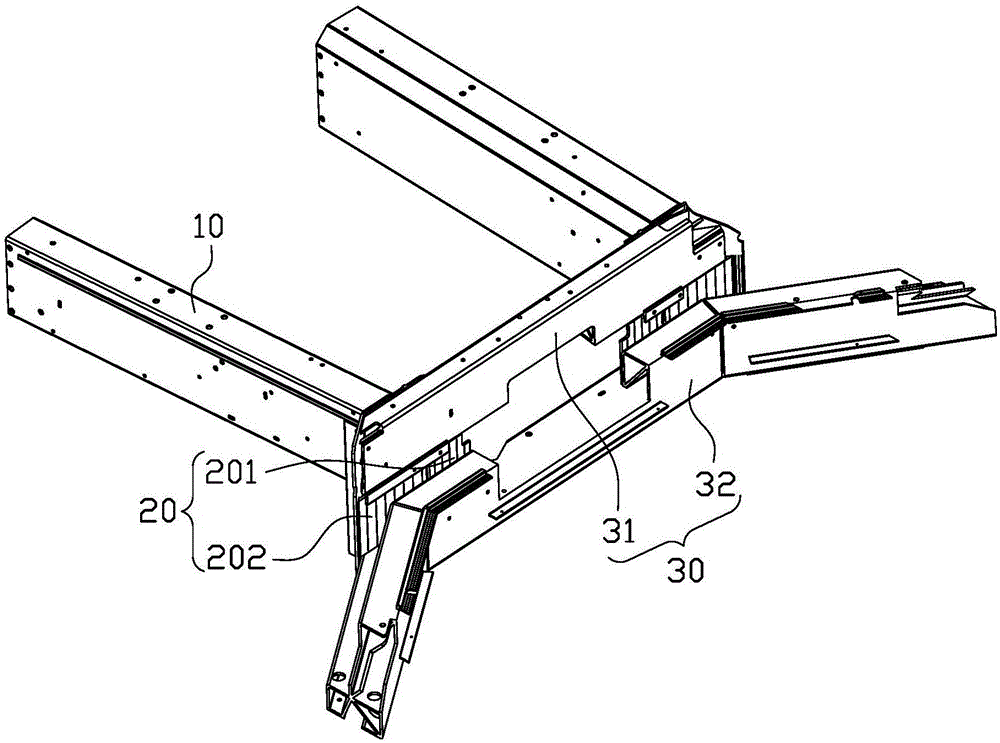

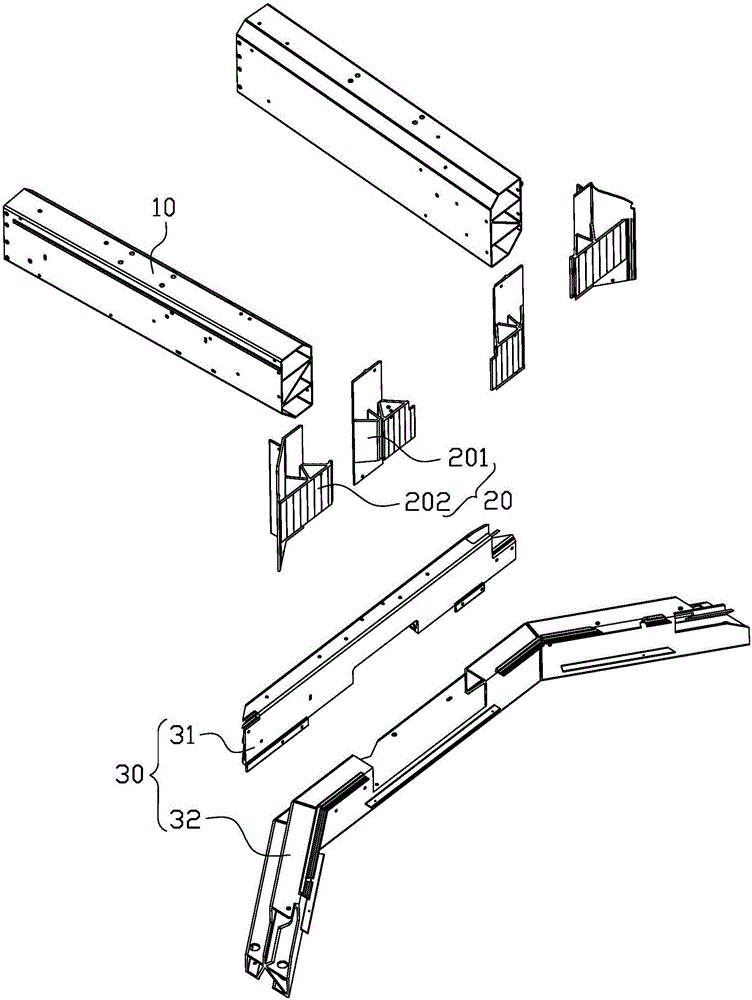

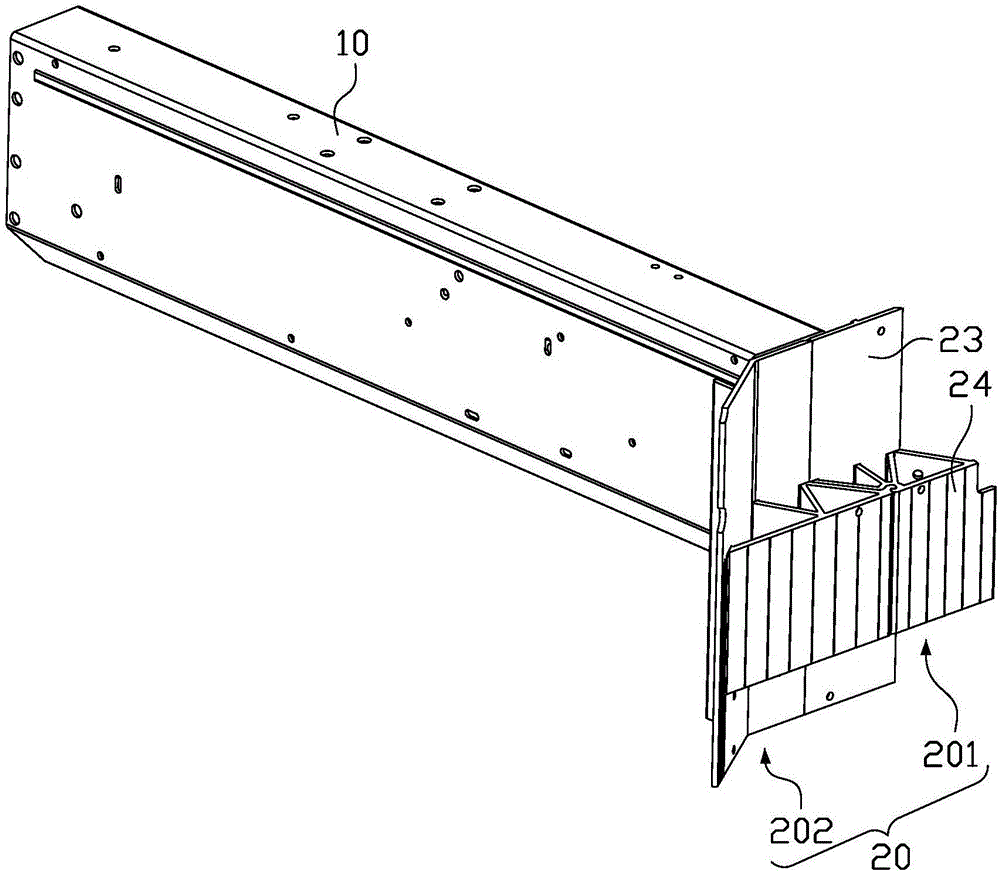

[0024] Such as figure 1 , figure 2 As shown, a connection structure between a longitudinal beam of an automobile cabin and a front wall cross member, the longitudinal beam of the automobile cabin includes two longitudinal beam assemblies 10 located on both sides of the automobile and extending along the front and rear direction of the automobile, the two longitudinal beam assemblies of the cabin The rear end of the 10 is connected to a front wall beam 30, and the two cabin longitudinal beam assemblies 10 are fixedly connected to the front wall beam 30 through a connecting structure 20, and the front end of the connecting structure 20 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com