Lightweight thick type board with fir core and bamboo peel veneer and preparation method thereof

A core board base material, fir wood technology, applied in the field of wood-based panel production, can solve the problems of limited board application fields, unstable board structure, complicated processing technology, etc., and achieve the effect of outstanding quality, light weight and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

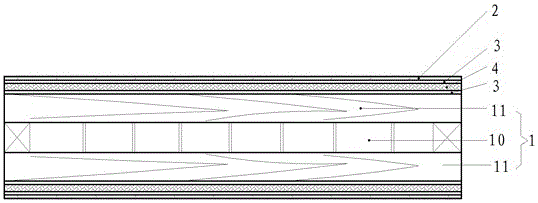

[0022] Such as figure 1 Shown, a kind of lightweight thick Chinese fir core of the present embodiment, the board material of bamboo veneer 2 veneer, comprises a core board base material 1, and described core board base material 1 is made of the timber framework 10 that is positioned at the middle part and with wood The upper and lower sides of the frame 10 are composed of respectively symmetrically glued perforated plates 11, the outer surface of the perforated plate 11 is pasted with bamboo skin 2, and the inner surface of the bamboo skin 2 is connected with the perforated plate through a plastic film layer 3. 11. The outer sides are laminated, and a layer of non-woven fabric 4 is laid in the middle of the plastic film layer 3 .

[0023] As can be seen from the above, the beneficial effects of the present invention are: the timber frame 10 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com