Working method of magnetic core test line body

A working method and magnetic core technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve the problems of easy misoperation, high production cost, manual operation, etc., and achieve the effect of improving stability and saving the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a working method for a magnetic core test wire body, and the specific steps are as follows:

[0025] S1, put the magnetic core into the jig at operator station 2;

[0026] S2, the transmission device transmits the jig to the press-in station 3, the blocking device blocks it, holds the positioning device to lift the jig, and starts to press it in. After pressing in, hold the positioning device to drop it and put it into the transmission device;

[0027] S3, the transfer device transfers the jig to the cleaning station 4, the blocking device and the holding and positioning device act as above, the cleaning device starts to clean, and after the cleaning is completed, the holding and positioning device drops it and puts it into the transfer device;

[0028] S4, the transfer device transfers the jig to the flipping station 5, the blocking device and the holding positioning device act as above, the manipulator flips the magnetic core by 90 degrees an...

Embodiment 2

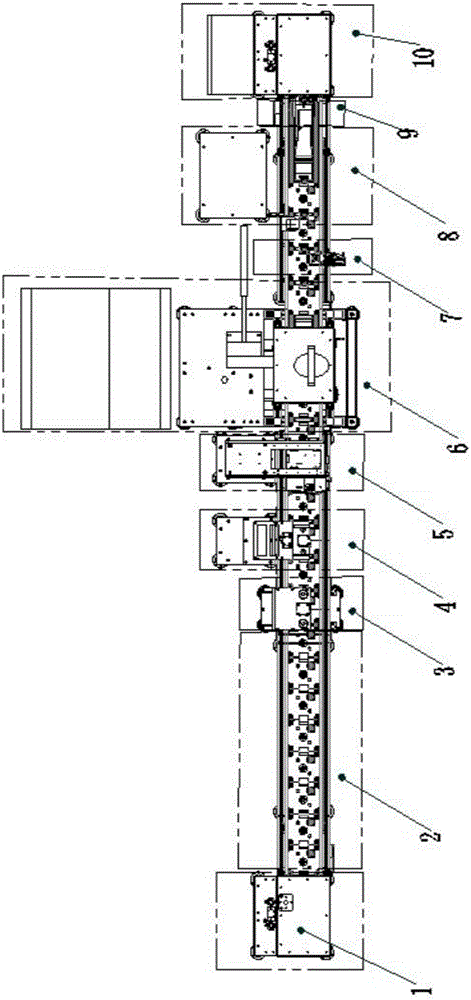

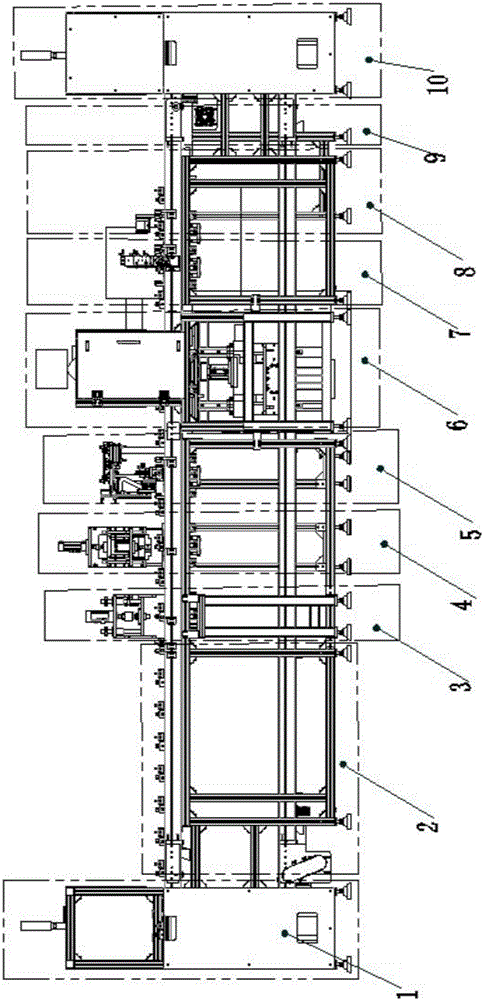

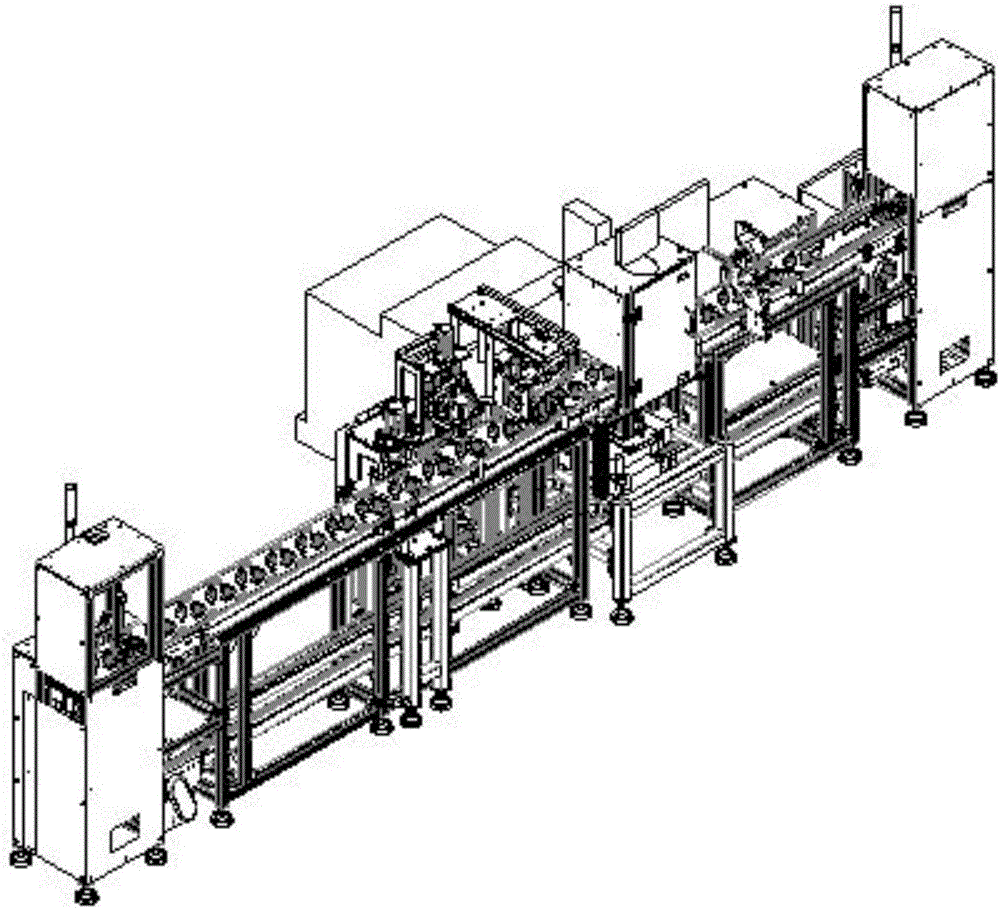

[0035] This embodiment provides a magnetic core test wire body as described in Embodiment 1, including: sequentially connected lifting device I1, operator station 2, press-in station 3, cleaning station 4, turning station 5, Welding station 6, on-off detection station 7, code scanning station 8, manual blanking station 9, lifting device II 10; the operator station 2, pressing station 3, cleaning station 4, turning station Station 5, welding station 6, on-off detection station 7, code scanning station 8, and manual blanking station 9 are all provided with blocking devices and holding positioning devices; the lifting device I1 is connected with operator station 2 Between operator station 2 and press-in station 3, press-in station 3 and cleaning station 4, cleaning station 4 and turning station 5, turning station 5 and welding station Between 6, between welding station 6 and on-off detection station 7, between on-off detection station 7 and code scanning station 8, between code s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com