Special drilling equipment for porous long shaft

A special equipment, long-axis technology, used in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve the problems of insufficient travel of the table guide rail, poor economy and adaptability, and inability to clamp , to achieve the effect of simple structure, low cost, easy installation and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

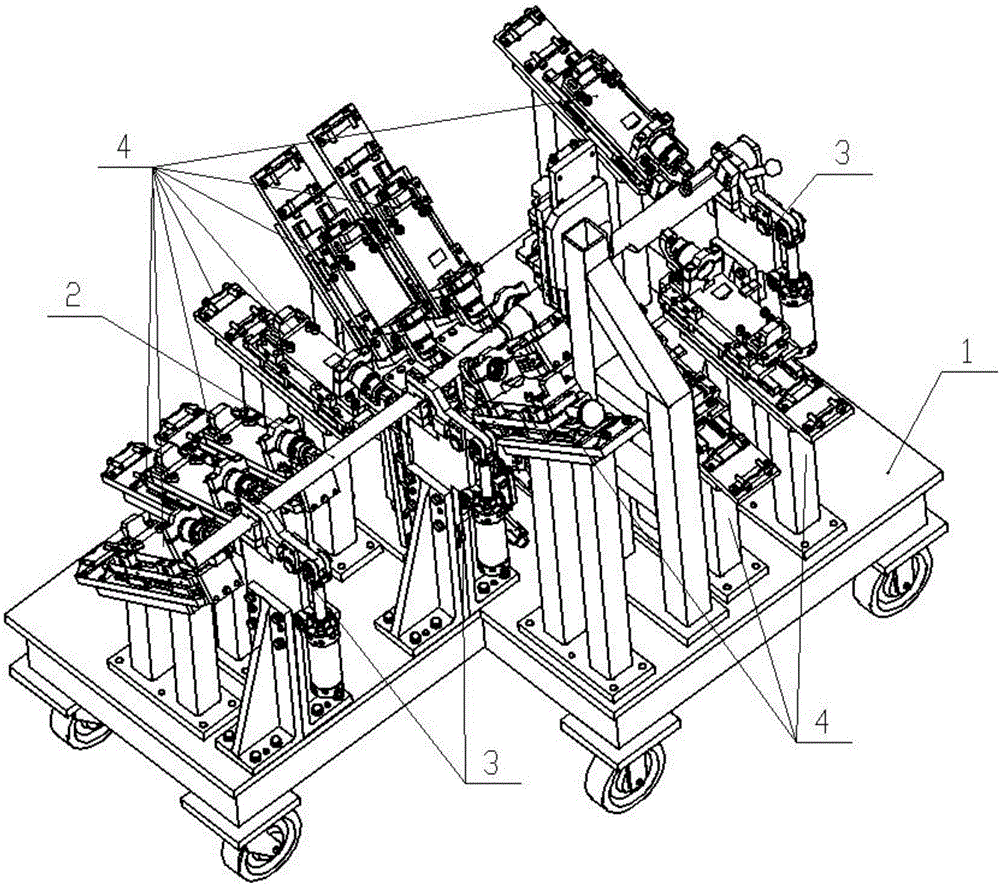

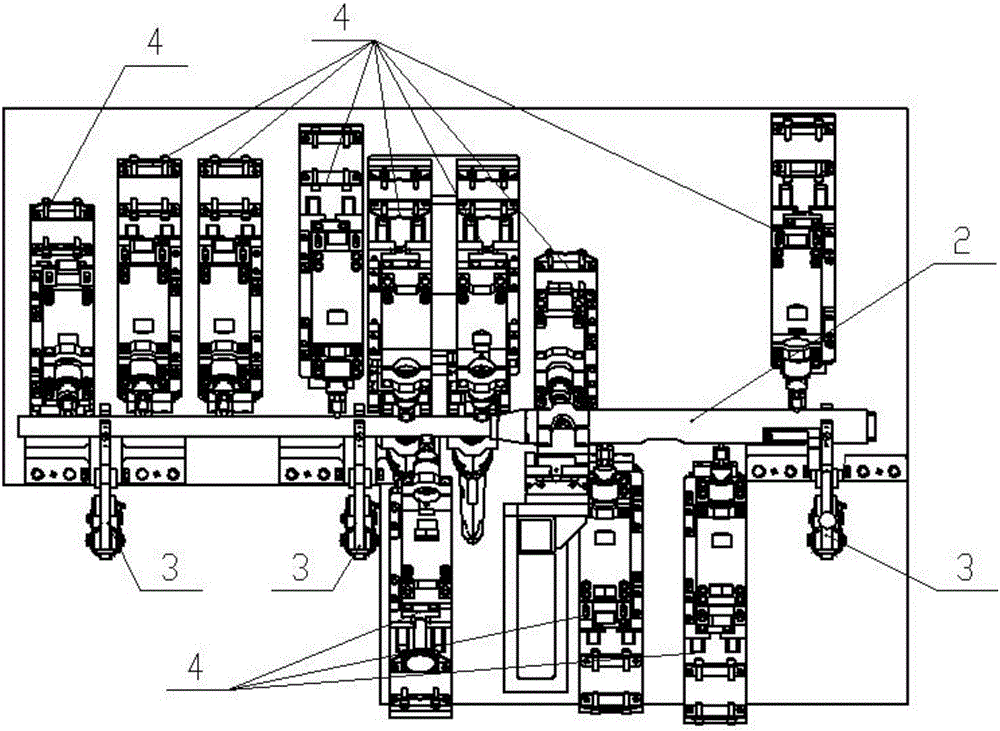

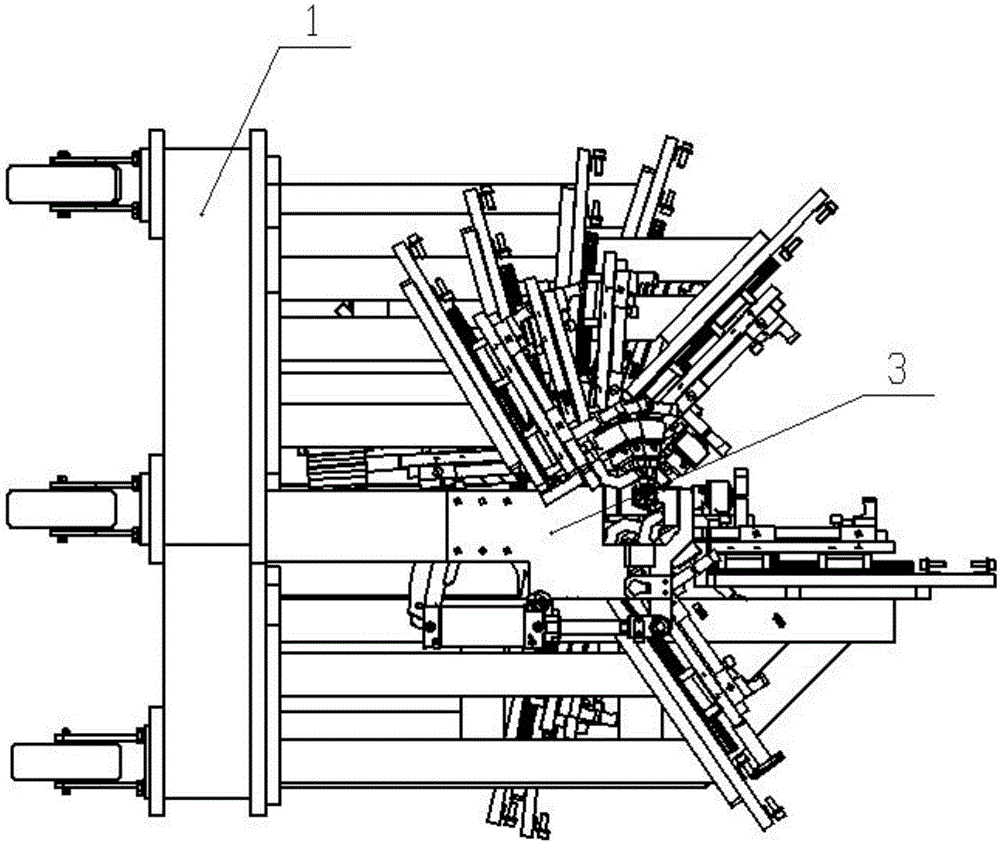

[0039] Such as figure 1 -Shown in -5, a kind of drilling special equipment of multi-hole long axis, comprises support 1 and is located on support 1 and is used for the fixture 3 that clamps long axis 2 usefulness and is used for drilling on long axis 2 Gun drill module 4.

[0040] Such as Figure 6As shown in -9, the clamp 3 includes a support frame 5, and the support frame 5 includes a pair of right-angled L-shaped steel plates 501 symmetrically arranged on the left and right, and a right-angled triangle is arranged between the two right-angled plates of the L-shaped steel plate 501. Ribs 502 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com