Sectional step type cooling device for hot rolling of high-strength steel bars

A high-strength steel bar and cooling device technology, applied in the direction of workpiece cooling devices, metal rolling, metal rolling, etc., can solve the problems of inflexible cooling paths, limited cooling speed of the core, poor corrosion resistance, etc., and achieve reduction The effect of fresh water consumption, increased strength, reduced alloy content and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

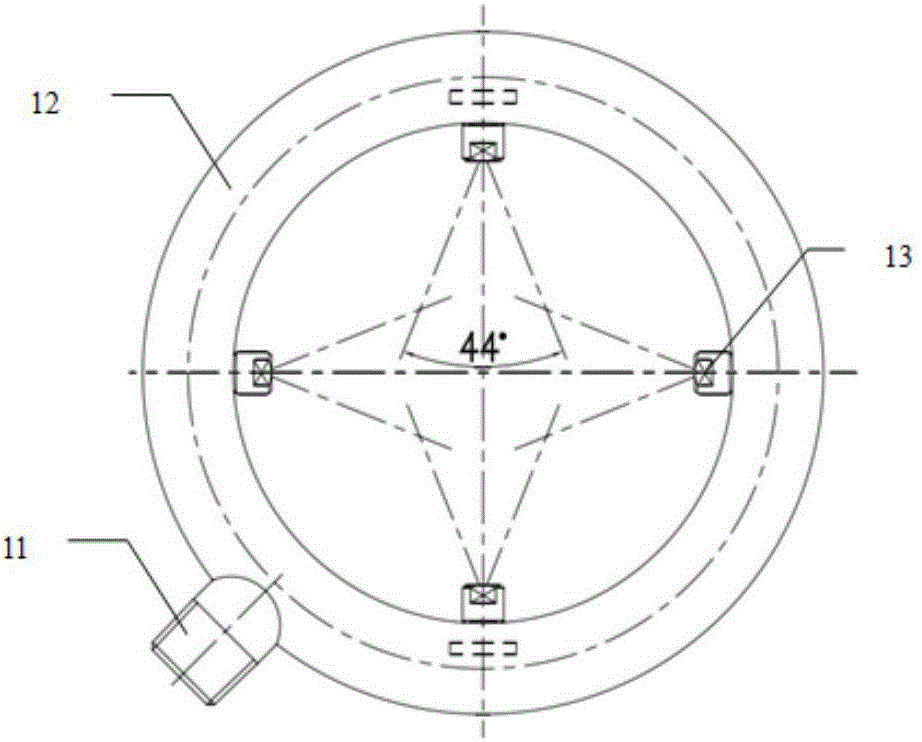

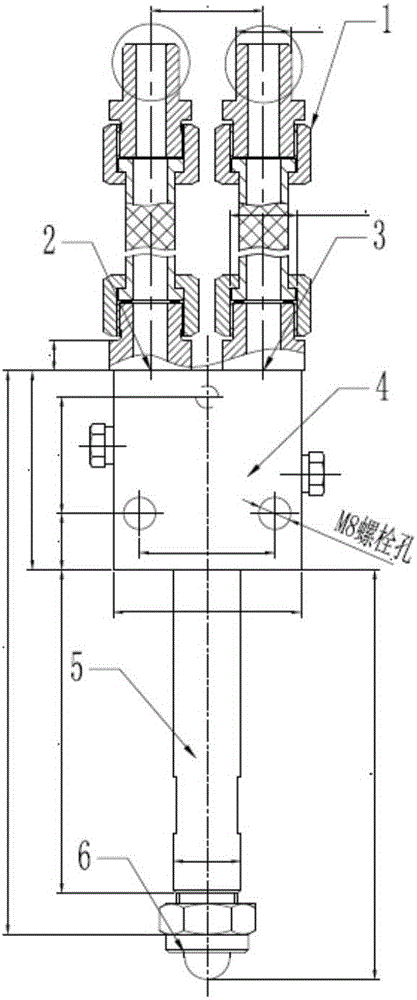

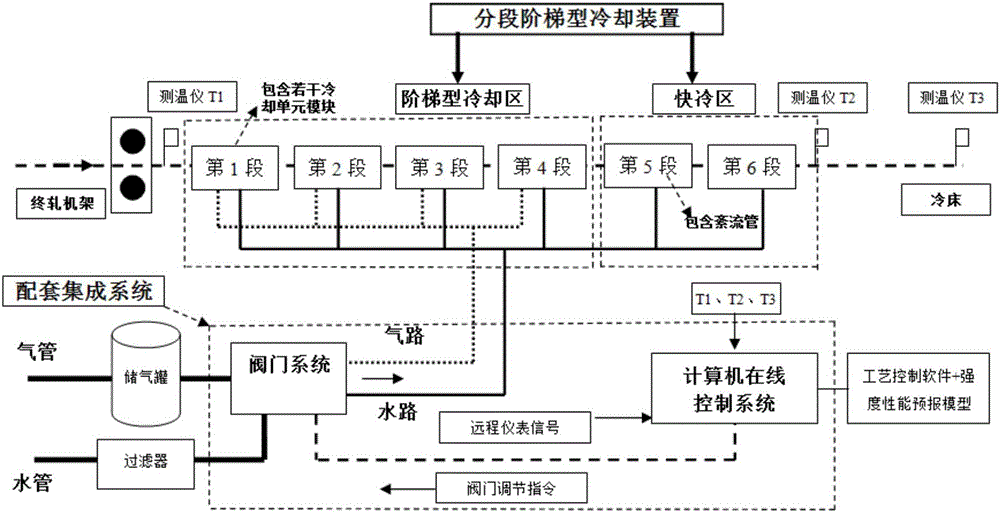

[0023] In order to illustrate the specific implementation of the step-by-step cooling device for a hot-rolled high-strength steel bar of the present invention, the following will be combined with the attached figure 1 -7, its basic principles, technical characteristics, actual operation and adjustment methods are explained as follows.

[0024] Such as figure 1 As shown, the stepwise cooling device for hot-rolled high-strength steel bars of the present invention is mainly composed of a stepwise cooling zone and a fast cooling zone. Among them, the step-by-step cooling zone is composed of 15 groups of water mist vaporization cooling nozzles and water mist strengthening nozzles in 4 sections, which is a cooling-returning step cooling section, and the water mist vaporization cooling nozzles and water mist strengthening nozzles are distributed at intervals; the fast cooling zone It consists of two sections of fast cooling turbulent tube coolers; the steel bars pass through the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com