Cutting and smashing all-in-one machine for agricultural straw and use method of cutting and smashing all-in-one machine

An all-in-one machine and straw technology, applied in grain processing and other directions, can solve the problems of poor crushing quality, inability to cut, material waste, etc., and achieve the effects of reducing floor space, improving crushing quality, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

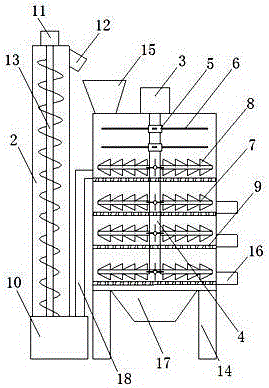

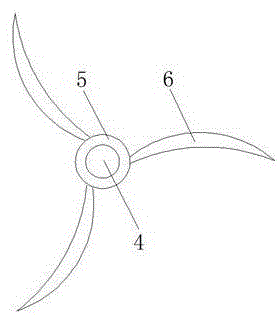

[0023] as attached Figure 1-2 As shown, a cutting and crushing integrated machine for agricultural straw includes a crushing box 1, a lifting cylinder 2, a motor 3, a transmission shaft 4, a connecting block 5, a cutting knife 6, a stirring rod 7, a crushing knife 8 and The filter screen 9 is characterized in that the crushing box 1 is arranged on the support 14, and the crushing box 1 is provided with a feed bin 15, a discharge pipe 16, and a miscellaneous discharge port 17. One end is provided with a material box 10, the other end is provided with a motor two 11, a discharge pipe 12, and an auger 13 is arranged in the material lifting cylinder 2, and one end of the auger 13 is connected with the motor two 11, and the material box 10 is connected to the crushing box 1 through the return pipe 18, and the agricultural straw is initially crushed and filtered through the filter screen 9, and the fragments of agricultural straw that are not fully crushed are transferred to the ma...

Embodiment 2

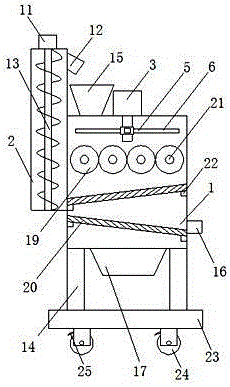

[0031] as attached image 3As shown, a cutting and crushing integrated machine for agricultural straw includes a crushing box 1, a lifting cylinder 2, a motor 3, a transmission shaft 4, a connecting block 5, a cutting knife 6, a crushing roller 19, a vibrating screen 20 and The walking wheel 24 is characterized in that the crushing box 1 is arranged on the bracket 14, and the crushing box 1 is provided with a feed bin 15, a discharge pipe 16, and a miscellaneous discharge port 17, and is provided on the inner wall of the crushing box 1 Vibration motor 22 is arranged, and described support 14 is arranged on the base plate 23, and one end of described material lifting cylinder 2 is arranged on the crushing box 1, and the other end is provided with motor two 11, discharge pipe 12, and in material lifting cylinder 2 An auger 13 is arranged inside, and one end of the auger 13 is connected to the motor 2 11. After the agricultural straw is initially crushed, it is filtered through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com