Green, smooth taste tobacco leaf treatment method

A processing method and technology of tobacco leaves, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problem of high labor cost, and achieve the effect of low input cost, simple method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

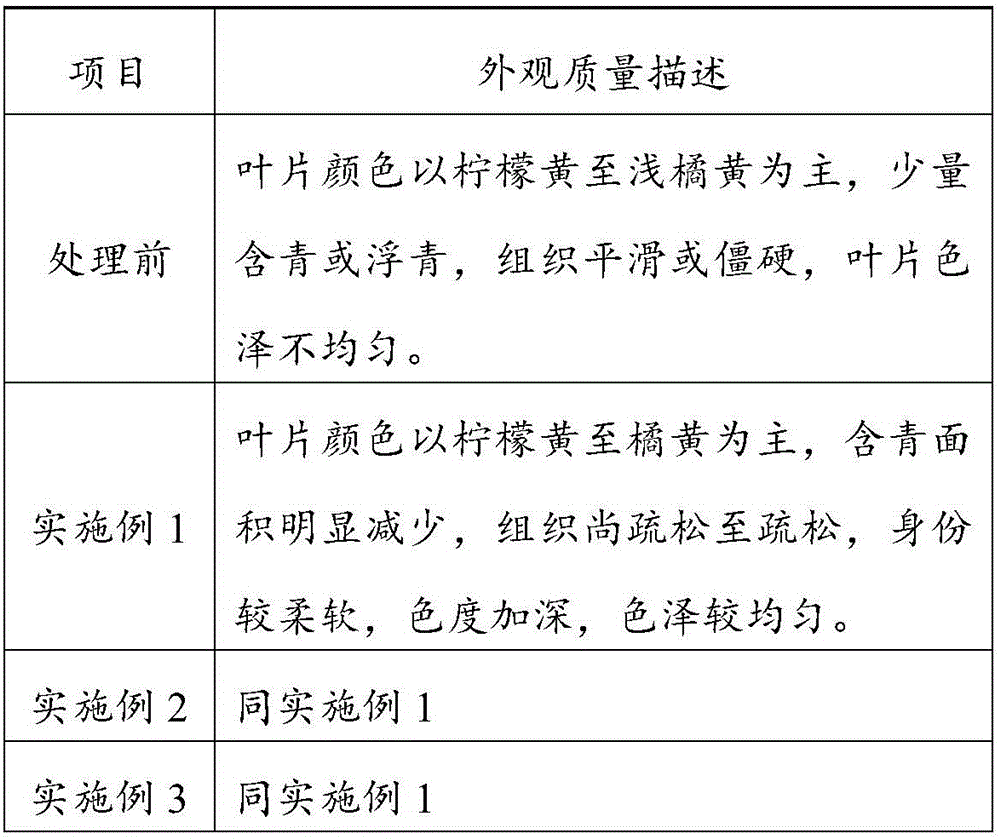

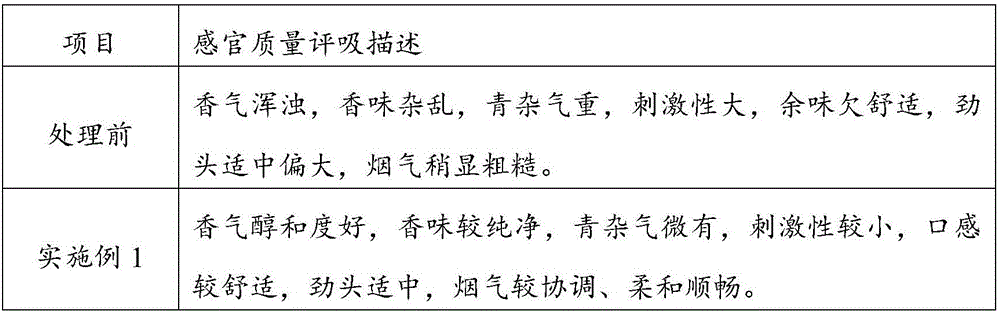

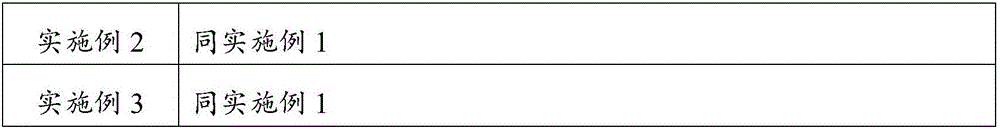

Examples

Embodiment 1

[0016] The first step, raw material preparation of tobacco leaves: collect 800kg of green and smooth leaves from the selection workshop in the selection workshop, and gather them together.

[0017] Second step, preparation of low-concentration alcohol solution: prepare 50 kg of alcohol solution with concentration of 6% in the laboratory of the rebaking factory, and set it aside for use.

[0018] The third step is to frame the tobacco leaves: use the steel tobacco frame of the tobacco re-baking factory to load the leaves, specifically including (1) evenly spread the collected tobacco leaf raw materials on the bottom of the tobacco frame, with the tip of the leaf facing inward and the petiole facing outward, Neatly stack; (2) when the stacking is 2-4cm thick, the 6% alcohol solution prepared in the second step is evenly sprayed on the leaves to ensure that the moisture content of the tobacco leaves is 18-20%; (3) continue Lay the leaves, then spray the solution, and reciprocate ...

Embodiment 2

[0022] The first step, raw material preparation of tobacco leaves: collect 3000kg of green and smooth leaves from the middle top grade tobacco in the selection workshop, and gather them together.

[0023] The second step, preparation of low-concentration alcohol solution: prepare 150 kg of 8% alcohol solution in the lab of the re-baking factory for use.

[0024] The third step is to frame the tobacco leaves: use the steel tobacco frame of the tobacco re-baking factory to load the leaves, specifically including (1) evenly spread the collected tobacco leaf raw materials on the bottom of the tobacco frame, with the tip of the leaf facing inward and the petiole facing outward, Neatly stack; (2) when the stacking is 2-4cm thick, the 8% alcohol solution prepared in the second step is evenly sprayed on the leaves to ensure that the moisture content of the tobacco leaves is 18-20%; (3) continue Lay the leaves, then spray the solution, and repeat until the frame is full; (4) When the f...

Embodiment 3

[0028] The first step, raw material preparation of tobacco leaves: collect 6000kg of green and smooth leaves from the selection workshop of the top grade tobacco in the middle, and gather them together.

[0029] The second step, the preparation of low-concentration alcohol solution: prepare 250 kg of 5% alcohol solution in the laboratory of the re-baking factory for use.

[0030] The third step is to frame the tobacco leaves. To pack the tobacco leaves in the steel cigarette frame of the tobacco rebaking factory, specifically include (1) evenly spread the collected tobacco leaf raw materials on the bottom of the tobacco frame, with the tip of the leaf facing inward and the petiole facing outward, and stacking neatly; (2) when When the stacking is 2-4cm thick, the 5% alcohol solution mist prepared in the second step is evenly sprayed on the blade to ensure that the moisture content of the tobacco leaf is 18-20%; (3) continue to spread the leaves, and then spray the solution, R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com