Threshing machine

A threshing machine and threshing technology, applied in agricultural machinery and tools, seed preservation through drying, threshing equipment, etc., can solve the problems of increased labor intensity, heavy volume, inapplicability, etc., and achieve a reasonable overall structure design, structural The effect of simple design and convenient promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific implementation example:

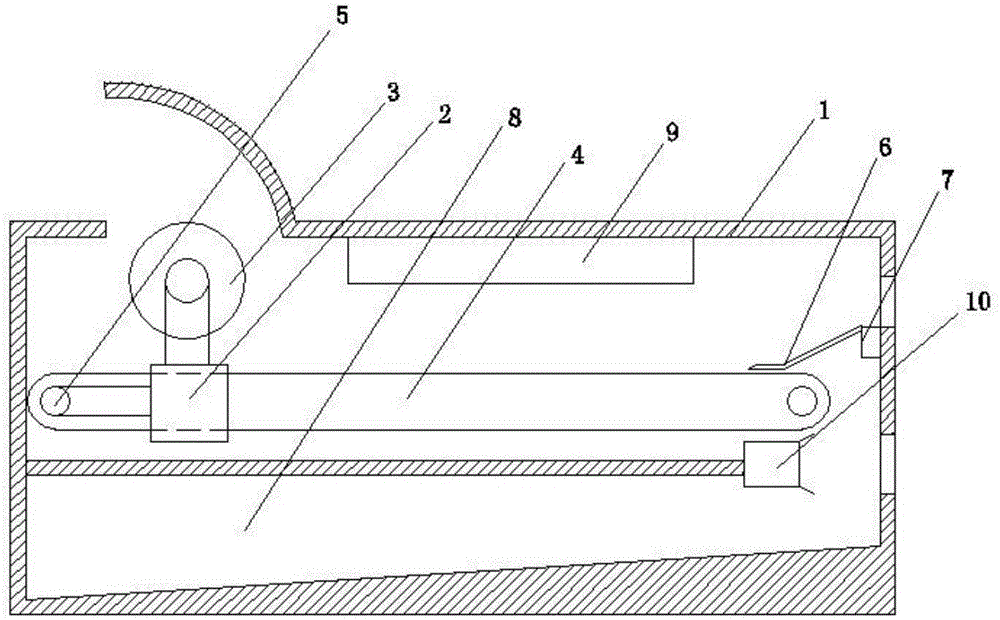

[0018] Such as figure 1 As shown, a threshing machine includes a casing 1, a motor 2, a threshing roller 3, a conveyor belt 4, a conveyor belt shaft 5, rake teeth 6, a vibrator 7, a barn 8, a heating device 9 and a blower 10. The bottom of the casing 1 is provided with a barn 8, and the bottom surface of the barn 8 is inclined to the left; the motor 2 is connected with the threshing roller 3 through a belt, and the motor 2 is also connected with the conveyor belt shaft 5; The conveyor belt 4 is arranged directly below the threshing cylinder 3, and the length of the conveyor belt 4 is equivalent to the length of the casing 1.

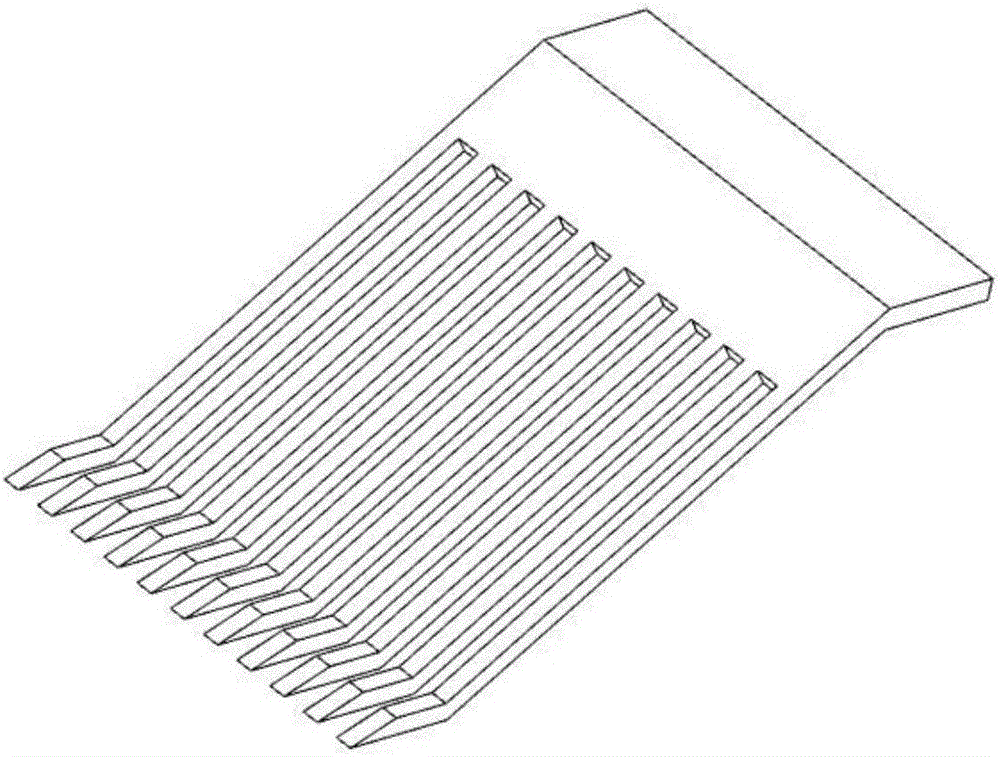

[0019] The right end of the conveyor belt 3 is provided with rake teeth 6, and the rake teeth 6 are obliquely arranged on the vibrator 7 at an inclination angle of 30°; the distance between the rake teeth 6 and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com