Potential type gas sensor based on Li3PO4-Li4SiO4 mixed solid electrolyte and preparation method thereof

A technology of gas sensor and solid electrolyte, which is applied in the direction of instruments, scientific instruments, and material analysis through electromagnetic means, which can solve the problems of selectivity difference, unsatisfactory sensor response time, large power consumption, etc., and achieve improved sensitivity and good human performance. The effect of machine interaction and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

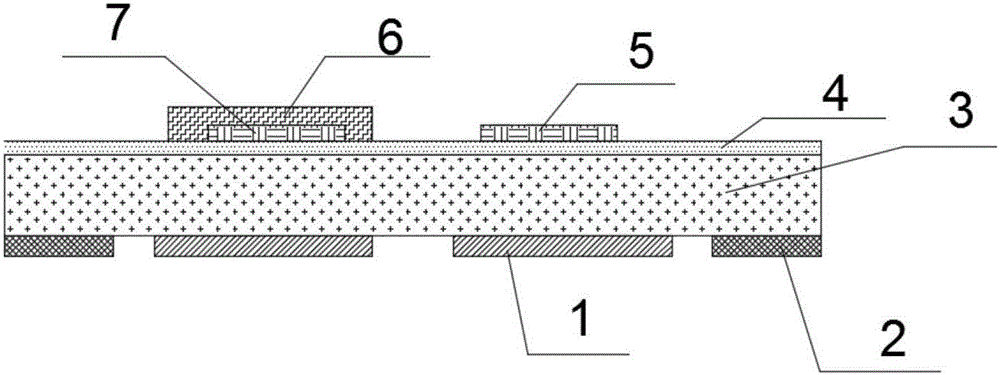

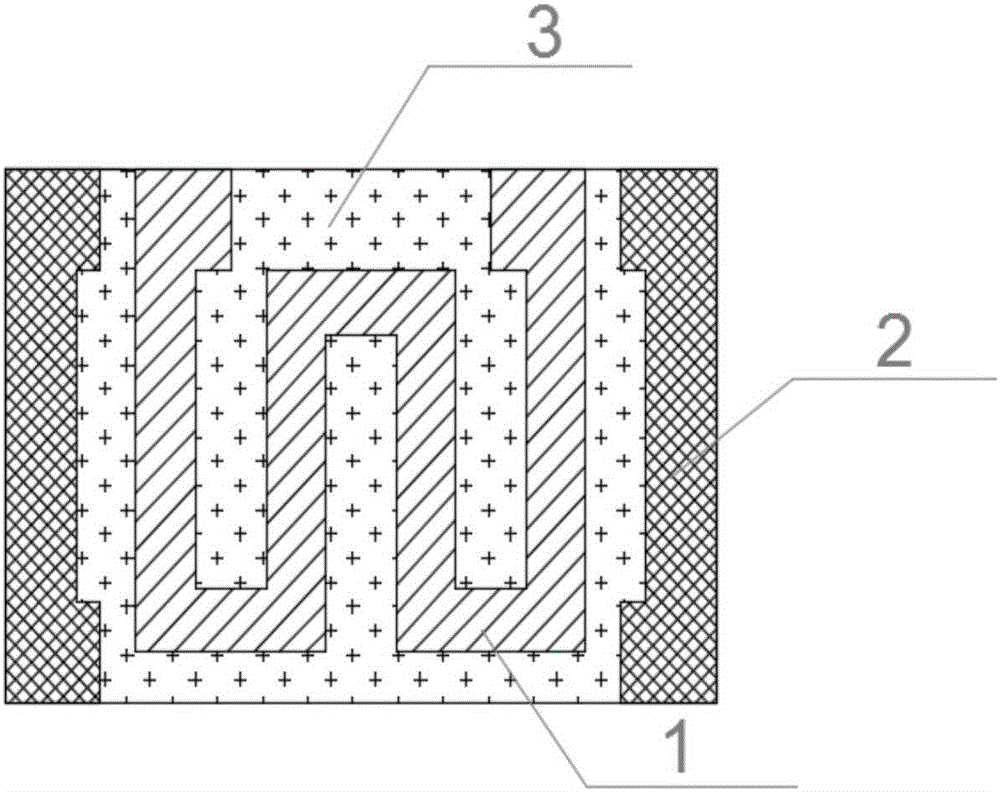

[0038] Such as figure 1 As shown, the present invention is based on Li 3 PO 4 -Li 4 SiO 4 Potentiometric gas sensors with mixed solid electrolytes, including Al 2 o 3 ceramic substrate 3, and distributed in Al 2 o 3 The film type Pt resistance temperature measuring electrode 1 and the Pt heating electrode 2 under the ceramic substrate 3 are placed on the Al 2 o 3 Li is distributed over the ceramic substrate 3 3 PO 4 -Li 4 SiO 4 Hybrid solid electrolyte film 4, Li 3 PO 4 -Li 4 SiO 4 A reference electrode Au film 5 and a reaction electrode Au film 7 are distributed on the mixed solid electrolyte film 4 , and the reaction electrode Au film 7 is covered with a chemical material 6 as a reaction electrode.

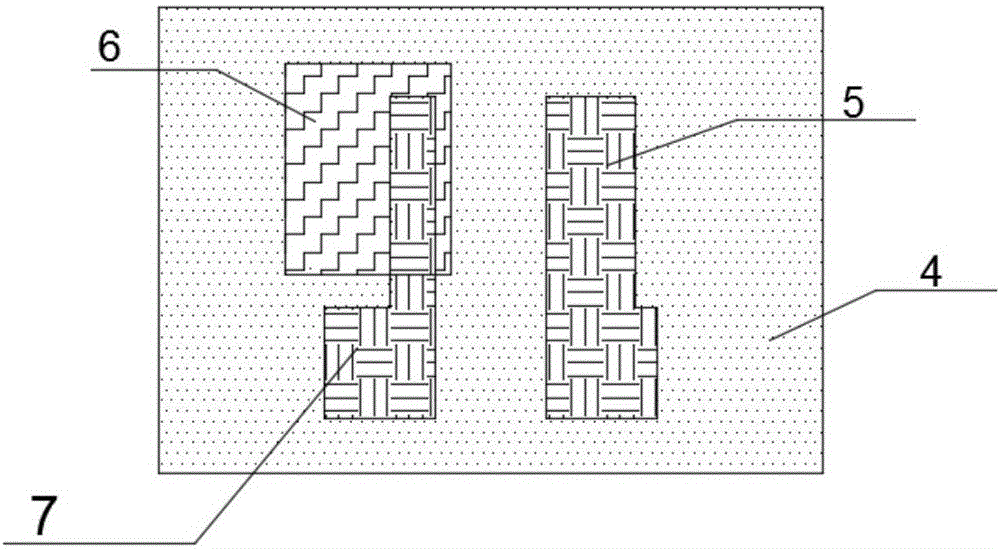

[0039] See figure 2 As shown, the width ratio of the reaction ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com