Flexible graphene composite material pressure sensor and preparation method thereof

A technology of pressure sensor and composite material, which is applied in the direction of fluid pressure measurement, instrument, and measurement force by changing the ohmic resistance. Focus on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

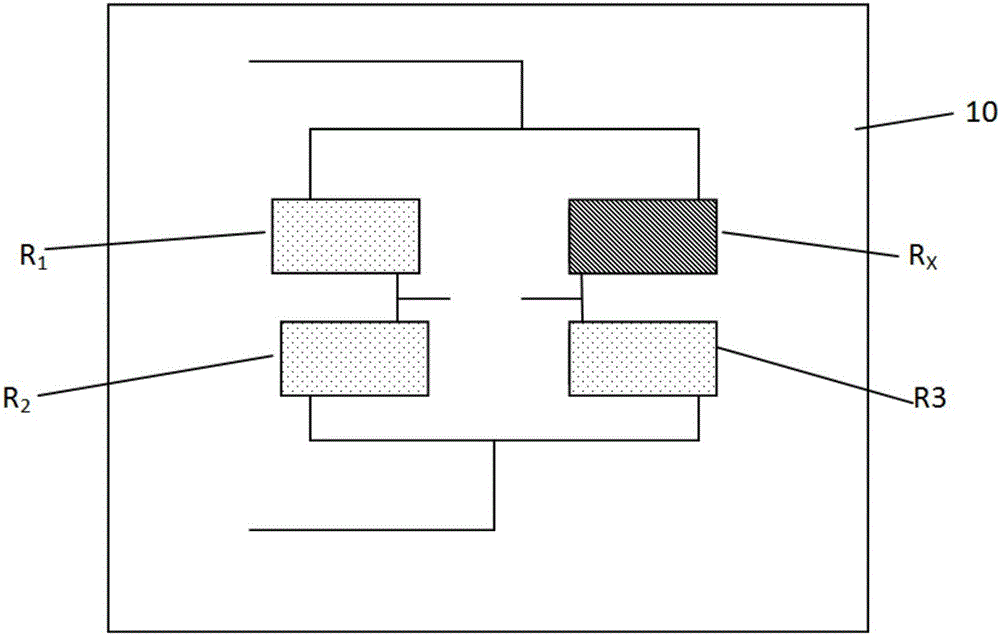

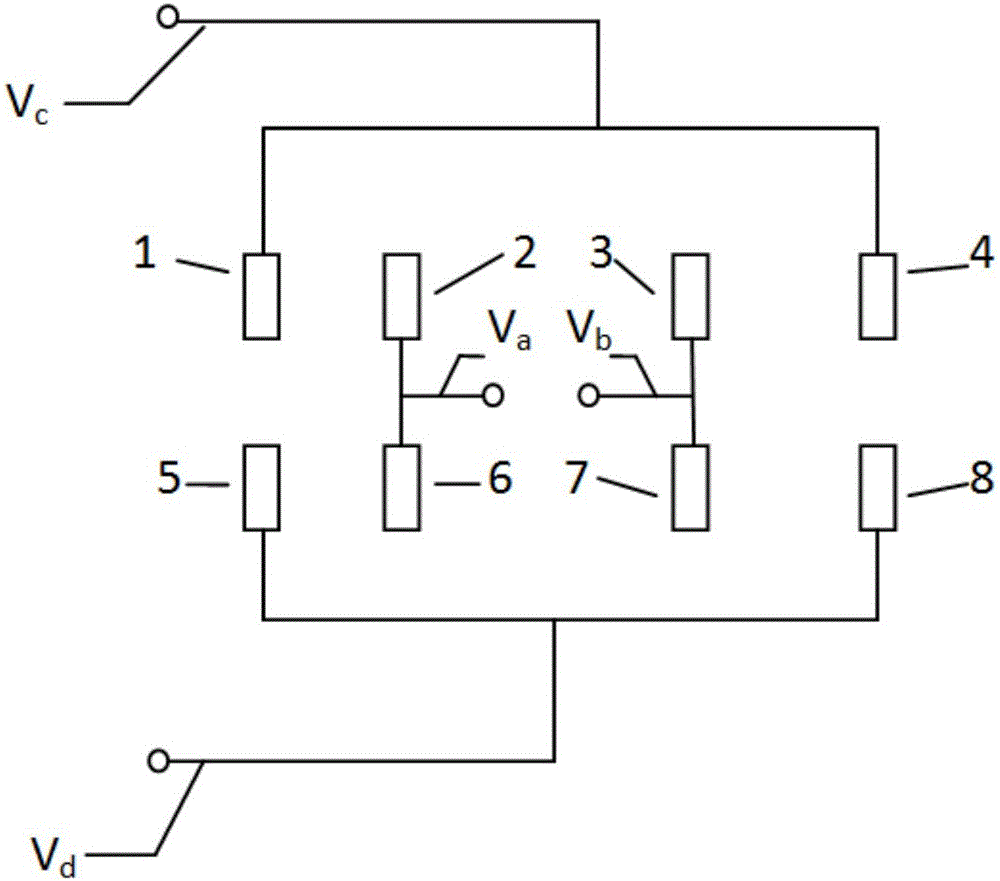

[0058] A flexible graphene composite pressure sensor, its top view is as follows figure 1 As shown, the cross-sectional view is as figure 2 As shown, it includes: a flexible substrate 10, electrodes and metal wiring, a force sensitive resistor layer, and a reference resistor layer; the flexible substrate 10 is at the bottom layer, and the electrodes and metal wiring are on the flexible substrate 10; Layer and reference resistance layer are above the electrodes and metal wiring; the schematic diagram of the electrode and metal wiring circuit is shown in image 3 shown.

[0059] There are 8 electrodes in total, electrode a1 and electrode b2 are adjacent to two electrodes of the same resistance, electrodes c3 and electrode d4 are adjacent to two electrodes of the same resistance, electrodes e5 and electrode f6 are adjacent to two electrodes of the same resistance, electrodes g7 and The electrode h8 is adjacent to two electrodes of the same resistance; the electrode a1 and the ...

Embodiment 2

[0100] A flexible graphene composite pressure sensor, its top view is as follows figure 1 As shown, the cross-sectional view is as figure 2 As shown, it includes: a flexible substrate 10, electrodes and metal wiring, a force sensitive resistor layer, and a reference resistor layer; the flexible substrate 10 is at the bottom layer, and the electrodes and metal wiring are on the flexible substrate 10; Layer and reference resistance layer are above the electrodes and metal wiring; the schematic diagram of the electrode and metal wiring circuit is shown in image 3 shown.

[0101] There are 8 electrodes in total, electrode a1 and electrode b2 are adjacent to two electrodes of the same resistance, electrodes c3 and electrode d4 are adjacent to two electrodes of the same resistance, electrodes e5 and electrode f6 are adjacent to two electrodes of the same resistance, electrodes g7 and The electrode h8 is adjacent to two electrodes of the same resistance; the electrode a1 and the ...

Embodiment 3

[0142] A flexible graphene composite pressure sensor, its top view is as follows figure 1 As shown, the cross-sectional view is as figure 2 As shown, it includes: a flexible substrate 10, electrodes and metal wiring, a force sensitive resistor layer, and a reference resistor layer; the flexible substrate 10 is at the bottom layer, and the electrodes and metal wiring are on the flexible substrate 10; Layer and reference resistance layer are above the electrodes and metal wiring; the schematic diagram of the electrode and metal wiring circuit is shown in image 3 shown.

[0143] There are 8 electrodes in total, electrode a1 and electrode b2 are adjacent to two electrodes of the same resistance, electrodes c3 and electrode d4 are adjacent to two electrodes of the same resistance, electrodes e5 and electrode f6 are adjacent to two electrodes of the same resistance, electrodes g7 and The electrode h8 is adjacent to two electrodes of the same resistance; the electrode a1 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com