Method and device for downhole cycle huff and puff recovery using supercritical carbon dioxide

A carbon dioxide and supercritical technology, which is applied in the fields of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of insufficient carbon dioxide recovery and increased greenhouse gas volume, so as to achieve less environmental pollution, avoid waste of resources, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

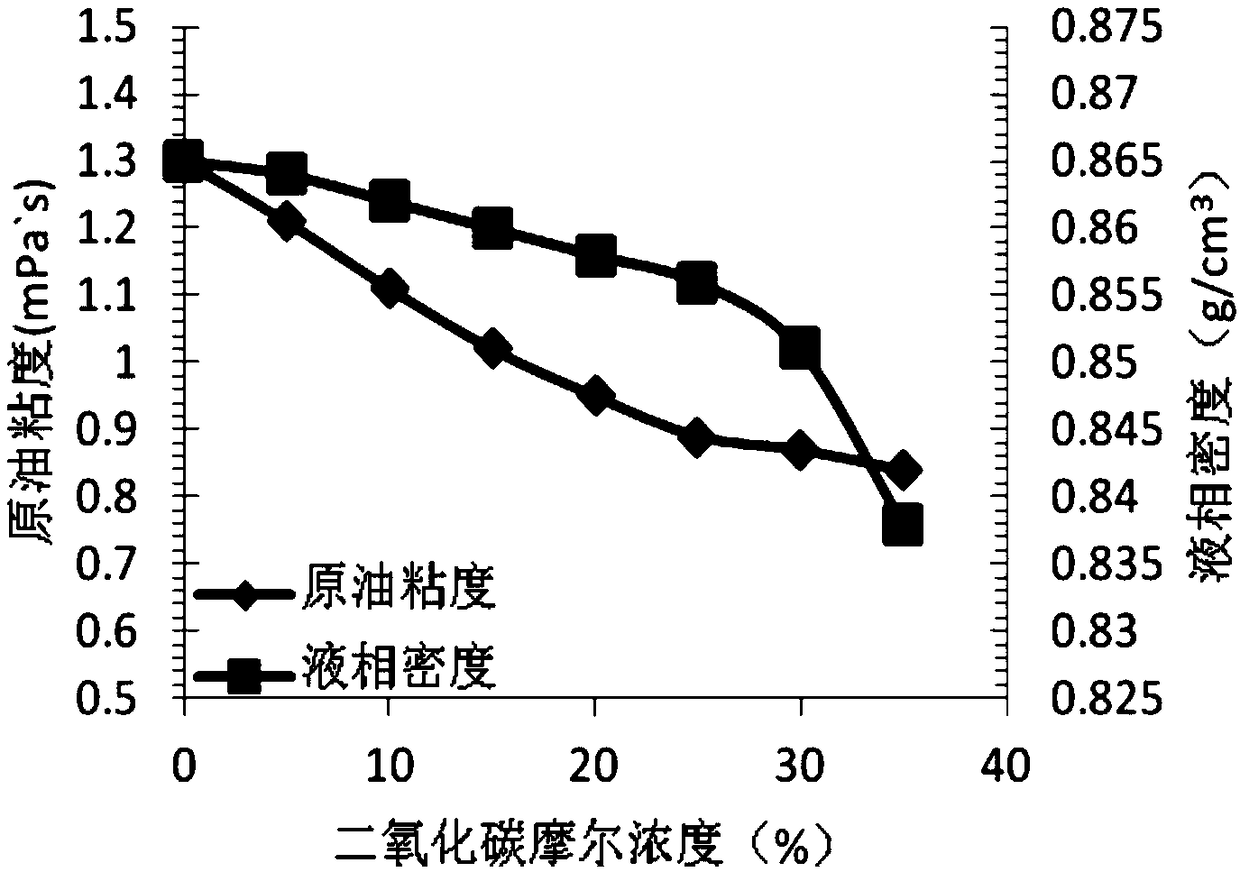

[0051] Embodiment 1 Taking the R53 block of JL Oilfield as the research object, a geological structure model, a sedimentary facies model and an attribute model under facies control are established for multiple wells in the block, and at the same time, the numerical simulation of production and water cut is completed on the basis of the geological model. For the fitting work, taking Well R53-3 in this block as an example, the oil production cycle huff and puff of this well was simulated to verify the feasibility of this method.

[0052] Well R53-3 is a horizontal well, where the interlayer interference is small, the oil layer is well sealed, and the gas injection trap can be formed. At the same time, the permeability of this area is low, and the pressure and temperature of the oil layer are high, which meets the requirement of supercritical injection. carbon dioxide conditions.

[0053] According to this embodiment, the method for downhole periodical huff and puff recovery usin...

Embodiment 2

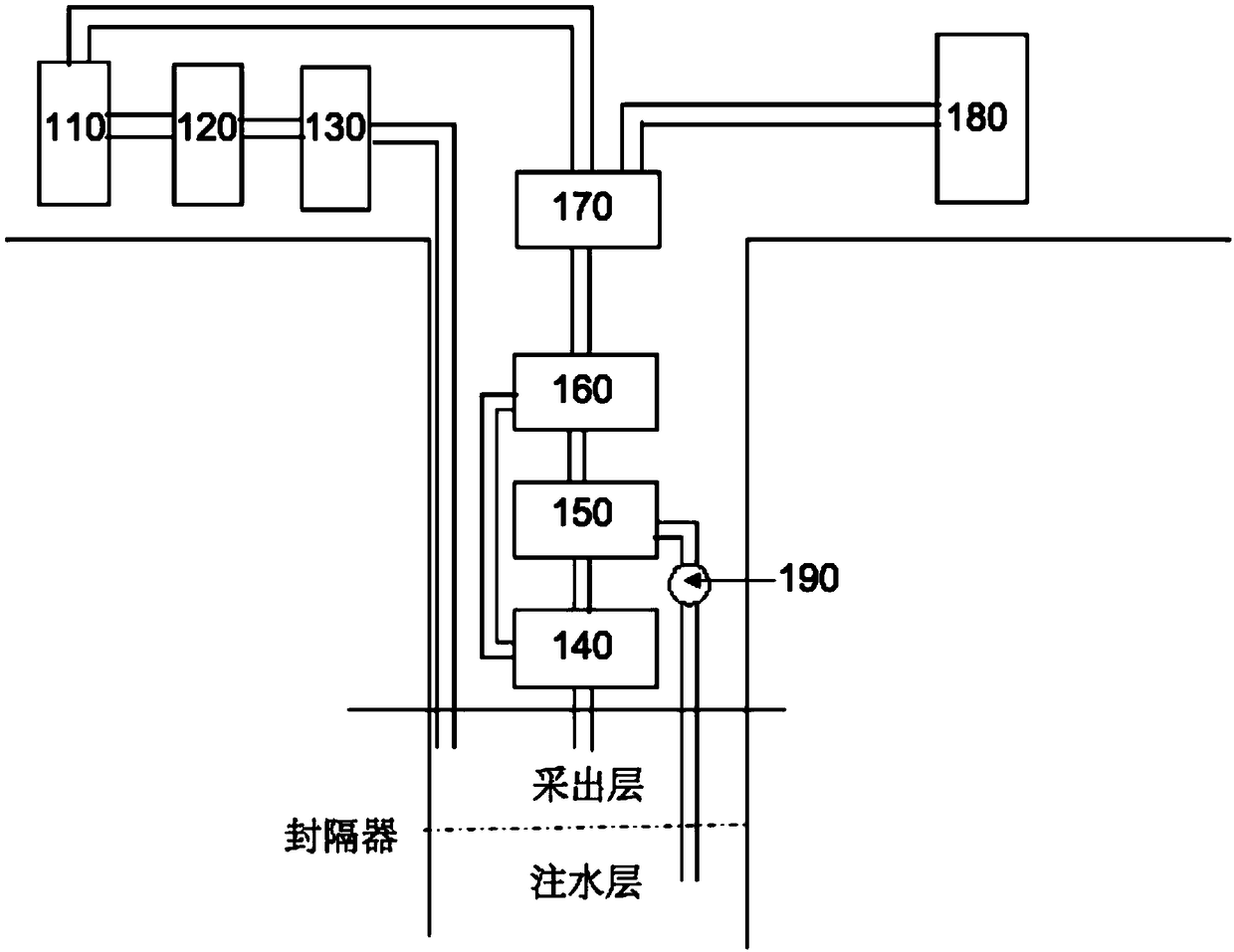

[0076] Such as figure 2 As shown, Embodiment 2 proposes a device for downhole periodic huff and puff oil recovery using supercritical carbon dioxide.

[0077] According to Embodiment 2, the device for downhole periodic huff and puff oil recovery utilizing supercritical carbon dioxide comprises: a carbon dioxide storage tank 110, a heater 120, a booster pump 130, a gas-liquid separator 140, an oil-water separator 150, an oil-gas mixing pump 160, an oil-gas Separator 170, oil storage tank 180.

[0078] The carbon dioxide storage tank 110, the heater 120, the booster pump 130 and the oil storage tank 180 are all arranged outside the well, and the gas-liquid separator 140, the oil-water separator 150, the oil-gas The mixing pump 160 and the oil-gas separator 170 are both arranged in the well; the carbon dioxide storage tank 110 is connected to the heater 120, and the heater 120 is connected to one end of the booster pump 130, and the booster pump The other end of 130 goes deep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com