Preparation method of non-dyeing nylon six-color silk

A nylon and colored yarn technology, applied in the field of spinning, can solve the problems of low solid measurement accuracy and precision, uneven mixing of the screw mixing head, etc., and achieves loose use environment requirements, good electromagnetic interference resistance, and flexible technology. good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

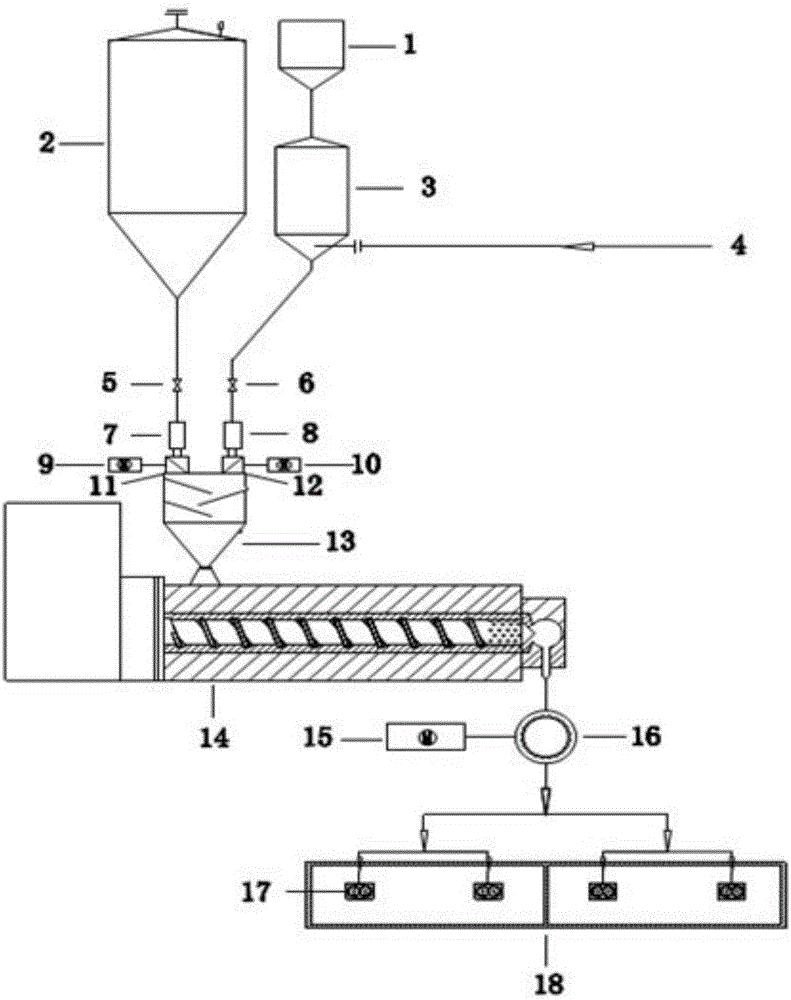

[0032] A preparation method of non-dyed nylon 6-color silk, comprising the following steps:

[0033] 1) Mixing: Add the pre-dried nylon 6 slices and masterbatch to the mixing device for mixing, wherein the masterbatch accounts for 3% of the weight.

[0034] 2) Melting: the polyamide 6 slices and the color masterbatch are mixed and melted under the heating and shearing of the screw extruder to obtain a spinning melt. Nylon 6 slices and color masterbatch are extruded in five stages in the screw extruder, and the temperatures are 245°C, 255°C, 265°C, 268°C, and 262°C.

[0035] 3) Dynamic mixing: the spinning melt flows out of the screw extruder and enters a dynamic mixing device for dynamic mixing.

[0036] 4) Spinning: The spinning melt enters the spinning box for spinning, and the monofilament is ejected from the spinneret.

[0037] 5) Bundle oiling: the monofilaments arrive at the bundle oiling point for bundling and oiling on the surface of the bundle. Wherein, when oiling...

Embodiment 2

[0041] A preparation method of non-dyed nylon 6-color silk, comprising the following steps:

[0042] 1) Mixing: Add the pre-dried nylon 6 slices and masterbatch to the mixing device for mixing, wherein the masterbatch accounts for 2% of the weight.

[0043] 2) Melting: the polyamide 6 slices and the color masterbatch are mixed and melted under the heating and shearing of the screw extruder to obtain a spinning melt. Nylon 6 chips and color masterbatch are extruded in five stages in the screw extruder, and the temperatures are 240°C, 250°C, 260°C, 265°C, and 260°C.

[0044] 3) Dynamic mixing: the spinning melt flows out of the screw extruder and enters a dynamic mixing device for dynamic mixing.

[0045] 4) Spinning: The spinning melt enters the spinning box for spinning, and the monofilament is ejected from the spinneret.

[0046]5) Bundle oiling: the monofilaments arrive at the bundle oiling point for bundling and oiling on the surface of the bundle. Wherein, when oiling, ...

Embodiment 3

[0050] A preparation method of non-dyed nylon 6-color silk, comprising the following steps:

[0051] 1) Mixing: Add the pre-dried nylon 6 slices and masterbatch to the mixing device for mixing, wherein the masterbatch accounts for 4% by weight.

[0052] 2) Melting: the polyamide 6 slices and the color masterbatch are mixed and melted under the heating and shearing of the screw extruder to obtain a spinning melt. Nylon 6 chips and color masterbatch are extruded in five stages in the screw extruder, and the temperatures are 250°C, 260°C, 270°C, 270°C, and 265°C.

[0053] 3) Dynamic mixing: the spinning melt flows out of the screw extruder and enters a dynamic mixing device for dynamic mixing.

[0054] 4) Spinning: The spinning melt enters the spinning box for spinning, and the monofilament is ejected from the spinneret.

[0055] 5) Bundle oiling: the monofilaments arrive at the bundle oiling point for bundling and oiling on the surface of the bundle. Wherein, when oiling, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com