Single-component exposed polyurethane waterproof paint and preparation method thereof

A polyurethane waterproof and exposed technology, applied in the field of polyurethane, can solve the problems of poor weather resistance and wear resistance, can not be used as decoration, low-strength waterproof coating, etc., achieves strong elongation, good scratch resistance, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

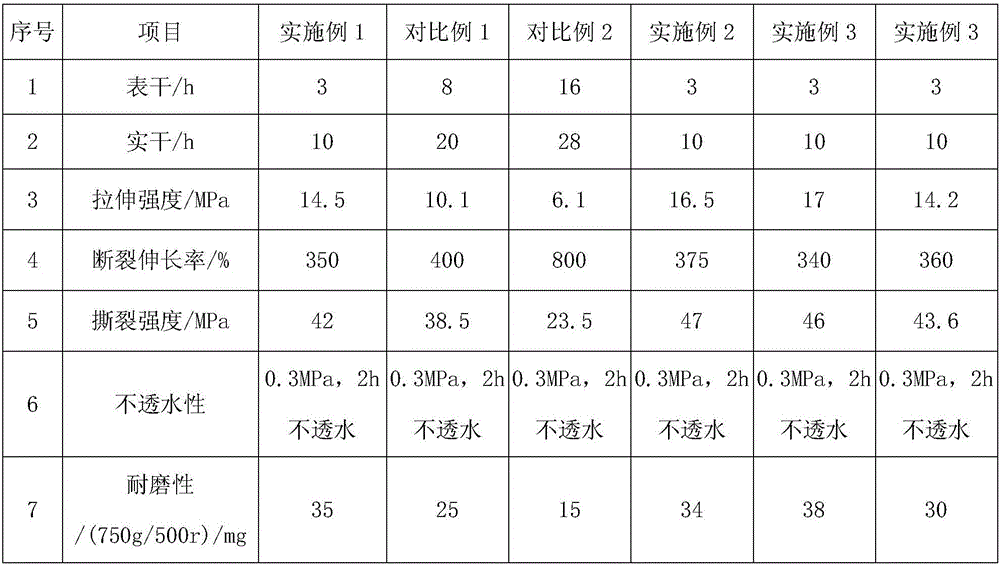

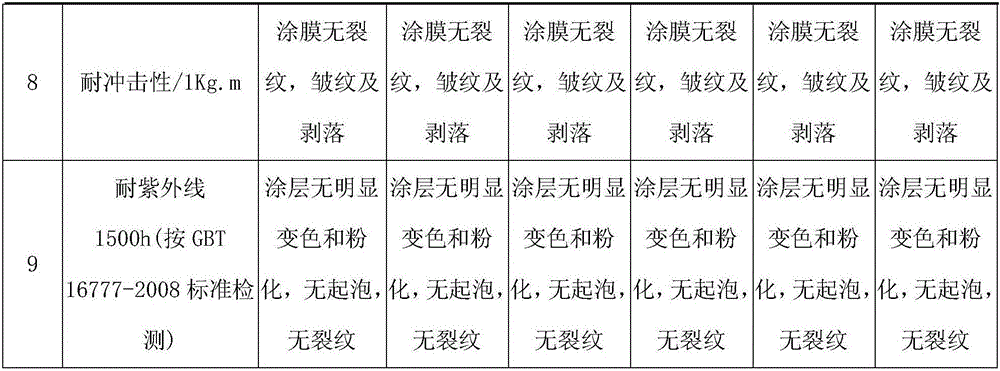

Embodiment 1

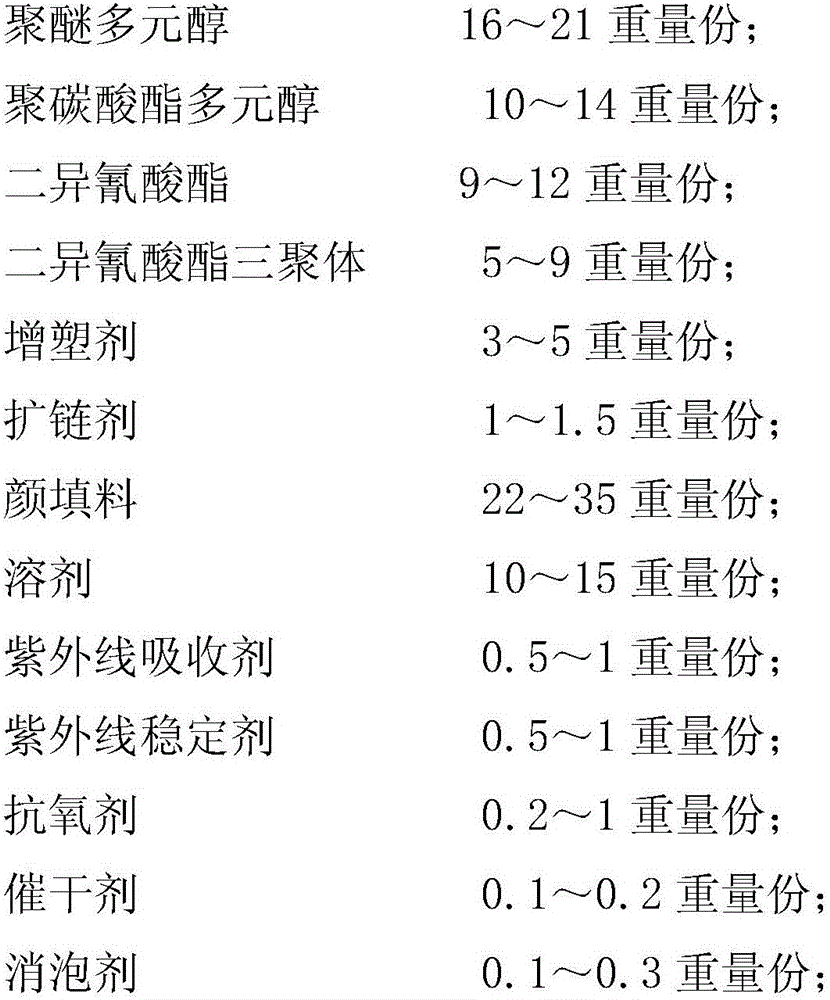

[0024] A one-component exposed polyurethane waterproof coating, its raw material components are: 21 parts by weight of polyether diol DL-2000, 10 parts by weight of polycarbonate diol T5652, 5 parts by weight of diphthalic acid diol Isononyl ester, 1.5 parts by weight of 1,4-butanediol, 15 parts by weight of talc, 10 parts by weight of titanium dioxide R-706, 2 parts by weight of nano-silica, 12 parts by weight of diisocyanate HMDI, 8 parts by weight of HDI trimer, 9 parts by weight of butyl acetate, 5 parts by weight of propylene glycol methyl ether acetate, 0.5 parts by weight of Tinuvin-928, 0.5 parts by weight of Tinuvin-770, 0.2 parts by weight of Irganox-245 , 0.2 parts by weight of BYK-066N, 0.1 parts by weight of drier T-12.

[0025] 1) Add polyether polyols, polycarbonate polyols, plasticizers, pigments and fillers into the reaction vessel, disperse evenly, stir and heat up to 100-110°C, dehydration at a relative vacuum of -0.08-0.1MPa 2 ~3 hours;

[0026] 2) Lower ...

Embodiment 2

[0044] A one-component exposed polyurethane waterproof coating, its raw material components are: 13 parts by weight polyether diol DL-2000, 3 parts by weight polyether diol 330N, 14 parts by weight polycarbonate diol T5652 , 5 parts by weight of diisononyl phthalate, 1.5 parts by weight of 1,4-butanediol, 16 parts by weight of talc, 10 parts by weight of titanium dioxide R-706, 2 parts by weight of nano-dioxide Silicon, 11 parts by weight of diisocyanate HMDI, 8 parts by weight of HDI trimer, 10 parts by weight of butyl acetate, 5 parts by weight of propylene glycol methyl ether acetate, 0.5 parts by weight of Tinuvin-928, 0.5 parts by weight of Tinuvin -770, 0.2 parts by weight of Irganox-245, 0.2 parts by weight of BYK-066N, 0.1 parts by weight of drier T-12.

[0045] 1) Add polyether polyols, polycarbonate polyols, plasticizers, pigments and fillers into the reaction vessel, disperse evenly, stir and heat up to 100-110°C, dehydration at a relative vacuum of -0.08-0.1MPa 2 ...

Embodiment 3

[0052] A single-component exposed polyurethane waterproof coating, its raw material components are: 15 parts by weight of polyether diol DL-2000, 13 parts by weight of polycarbonate diol T5652, 5 parts by weight of diphthalic acid diol Isononyl ester, 1 weight part of 1,4-butanediol, 22 weight parts of talcum powder, 10 weight parts of titanium dioxide R-706, 2.5 weight parts of nano silicon dioxide, 10 weight parts of diisocyanate HMDI, 5 parts by weight of HDI trimer, 10 parts by weight of butyl acetate, 5 parts by weight of propylene glycol methyl ether acetate, 0.5 parts by weight of Tinuvin-928, 0.5 parts by weight of Tinuvin-770, 0.2 parts by weight of Irganox-245 , 0.2 parts by weight of BYK-066N, 0.1 parts by weight of drier T-12.

[0053] 1) Add polyether polyols, polycarbonate polyols, plasticizers, pigments and fillers into the reaction vessel, disperse evenly, stir and heat up to 100-110°C, dehydration at a relative vacuum of -0.08-0.1MPa 2 ~3 hours;

[0054] 2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com