Fuel oil feed inlet gasket rubber compound

A feeding port and gasket technology, applied to products, educts, reagents, etc., can solve problems such as short-term failure of products, degradation of rubber properties and other properties, and insufficient aging resistance

Active Publication Date: 2017-02-08

TIANJIN HUANYU RUBBER & PLASTIC CO LTD

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the automobile industry, machinery manufacturing, oil extraction, oil refining and other industrial production, it is necessary to use rubber products in the process of oil transmission such as fuel oil, lubricating oil, hydraulic oil, etc. However, the rubber produced by nitrile rubber (NBR) All products have deficiencies in aging resistance

If rubber products are in contact with oil medium for a long time during use, the oil can penetrate into the product to cause volume expansion, resulting in a decrease in the chemical and other properties of the rubber, resulting in short-term failure or failure of the product; and some exposed to the air Products must also withstand the influence of ozone and high temperature, so it is imminent to find a material that is resistant to oil, high temperature and ozone

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0052] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the best embodiments.

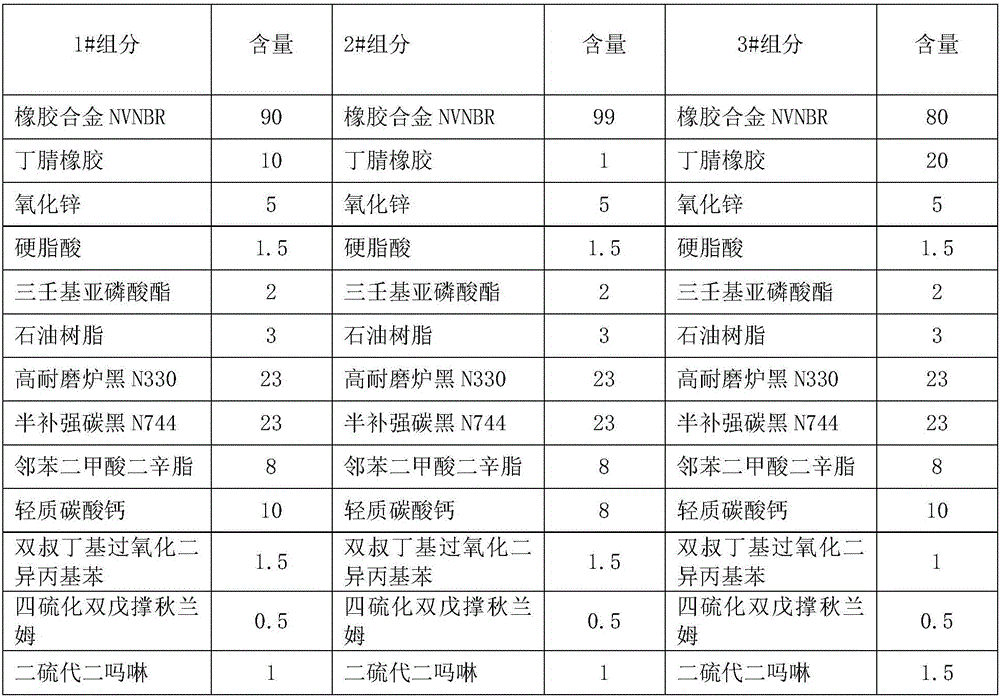

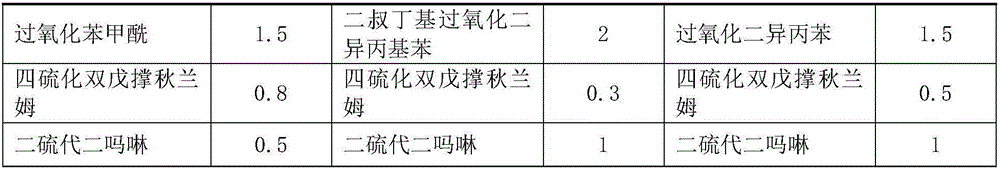

[0053] Table 1 shows the different amounts of each component, in parts by mass kg:

[0054] Table 1

[0055]

[0056]

[0057]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of rubber and specifically relates to a fuel oil feed inlet gasket rubber compound. The fuel oil feed inlet gasket rubber compound comprises the following ingredients (by weight): 100 parts of a mixture of rubber alloy NVNBR and nitrile rubber, 4-6 parts of zinc chloride, 1-1.5 parts of stearic acid, 1-3 parts of trinonylphosphite, 2-4 parts of petroleum resin, 40-50 parts of a strengthening agent, 8-10 parts of a plasticizer, 8-10 parts of light calcium carbonate, 1-2 parts of a cross-linking agent, 0.3-0.8 part of a promoter and 0.5-1.5 parts of sulfur-donor. Mass content of the rubber alloy NVNBR is 30-35 wt%. Mass ratio of butyronityile to polyvinyl chloride is 7:3. The invention provides the fuel oil feed inlet gasket rubber compound which can satisfy superior resistance to fuel oil D and No. IRM903 fuel oil, satisfy superior resistance to high temperature 100 DEG C and thermal ageing performance and has no crack or fracture at low temperature of minus 30 DEG C under the condition of 3min brittleness and has ozone resistance.

Description

technical field [0001] The invention belongs to the technical field of rubber, and in particular relates to a rubber material for a gasket of a fuel filling port. Background technique [0002] In the automobile industry, machinery manufacturing, oil extraction, oil refining and other industrial production, it is necessary to use rubber products in the process of oil transmission such as fuel oil, lubricating oil, hydraulic oil, etc. However, the rubber produced by nitrile rubber (NBR) The products all have deficiencies in aging resistance. If rubber products are in contact with oil medium for a long time during use, the oil can penetrate into the product to cause volume expansion, resulting in a decrease in the chemical and other properties of the rubber, resulting in short-term failure or failure of the product; and some exposed to the air Products must also withstand the effects of ozone and high temperature, so it is urgent to find a material that is both oil-resistant a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L9/02C08L27/06C08L57/02C08K13/02C08K3/22C08K5/09C08K5/524C08K3/04C08K5/12C08K3/26C08K5/14C08K5/40

CPCC08L9/02C08L2205/035C08L2205/025C08L2201/08C08L27/06C08L57/02C08K13/02C08K2003/2296C08K5/09C08K5/524C08K3/04C08K5/12C08K2003/265C08K5/14C08K5/40Y02P20/143

Inventor 刘振宁耕

Owner TIANJIN HUANYU RUBBER & PLASTIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com