A kind of preparation method of titanium silicon molecular sieve with hierarchical pores

A technology of titanium-silicon molecular sieves and channels, which is applied in the direction of molecular sieve compounds, molecular sieve catalysts, molecular sieve characteristic silicates, etc., can solve the problems that PVA cannot play the template role, phase separation, precursor solution weakening, etc., and achieve excellent catalytic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Under the condition of continuous stirring, 23.4g tetrapropylammonium hydroxide (20wt%) was slowly added in 15.0g tetraethyl orthosilicate, after tetraethyl orthosilicate was completely hydrolyzed, a colorless and transparent solution A was obtained; then , the mixed solution B of 0.72g titanium source and 2.4g isopropanol is slowly added in solution A to obtain colorless and transparent solution C; ) after being fully mixed, the solution was transferred to a hydrothermal reaction kettle, first crystallized at 90° C. for 24 hours, and then heated to 160° C. for 24 hours. After the obtained product was centrifuged and washed, it was dried at 110°C overnight, and finally the obtained solid was calcined at 550°C for 6 hours to finally obtain the multi-level channel TS-1.

Embodiment 2

[0032] Under the condition of continuous stirring, 23.4g tetrapropylammonium hydroxide (20wt%) was slowly added in 15.0g tetraethyl orthosilicate, after tetraethyl orthosilicate was completely hydrolyzed, a colorless and transparent solution A was obtained; then , the mixed solution B of 0.72g titanium source and 2.4g isopropanol was slowly added to solution A to obtain a colorless and transparent solution C; after solution C was removed from alcohol at 80°C for 2h, it was mixed with PVA solution of the same quality (10.0wt%) ) after being fully mixed, the solution was transferred to a hydrothermal reaction kettle, first crystallized at 90° C. for 24 hours, and then heated to 160° C. for 24 hours. After the obtained product was centrifuged and washed, it was dried at 110°C overnight, and finally the obtained solid was calcined at 550°C for 6 hours to finally obtain the multi-level channel TS-1.

Embodiment 3

[0034] Under the condition of continuous stirring, 23.4g tetrapropylammonium hydroxide (20wt%) was slowly added in 15.0g tetraethyl orthosilicate, after tetraethyl orthosilicate was completely hydrolyzed, a colorless and transparent solution A was obtained; then , the mixed solution B of 0.72g titanium source and 2.4g isopropanol was slowly added to solution A to obtain a colorless and transparent solution C; after solution C was removed from alcohol at 80°C for 2h, it was mixed with PVA solution of the same quality (15.0wt%) ) after being fully mixed, the solution was transferred to a hydrothermal reaction kettle, first crystallized at 90° C. for 24 hours, and then heated to 160° C. for 24 hours. After the obtained product was centrifuged and washed, it was dried at 110°C overnight, and finally the obtained solid was calcined at 550°C for 6 hours to finally obtain the multi-level channel TS-1.

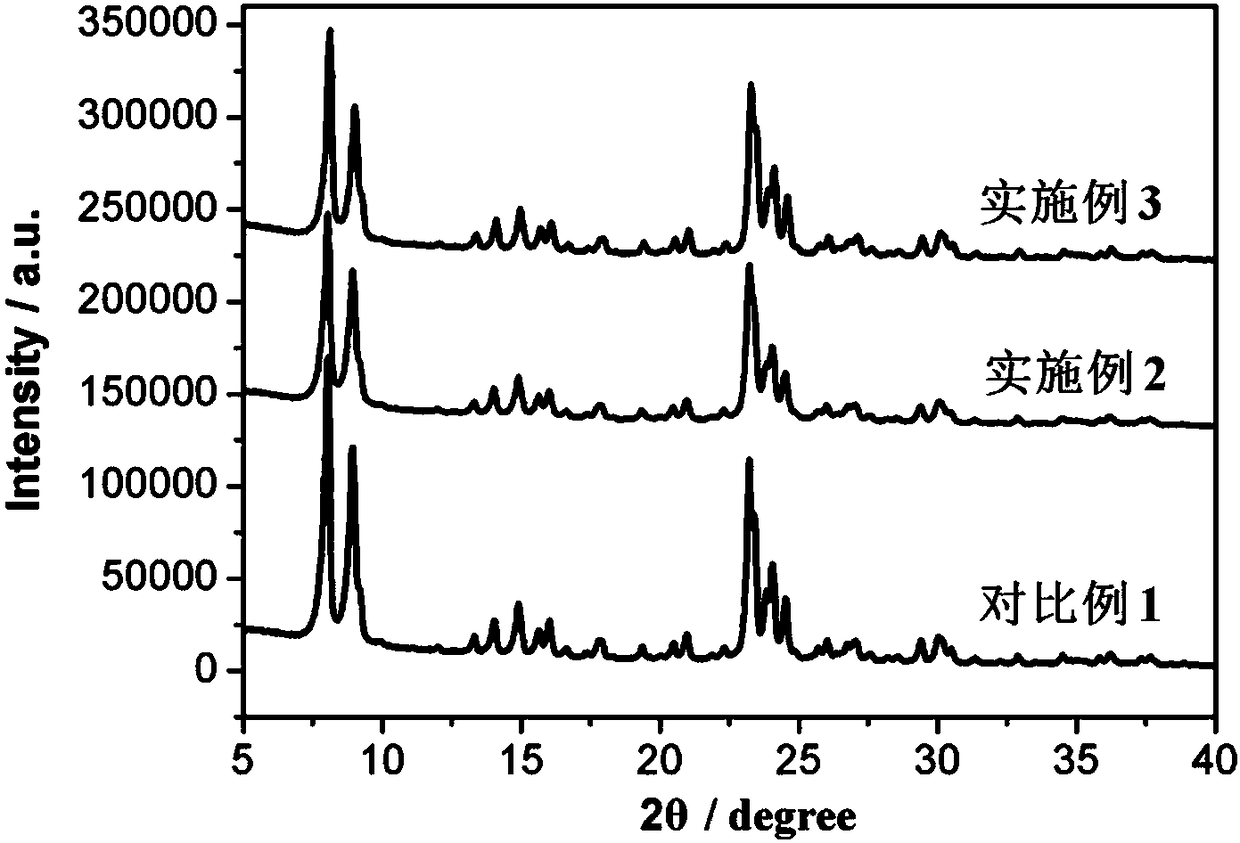

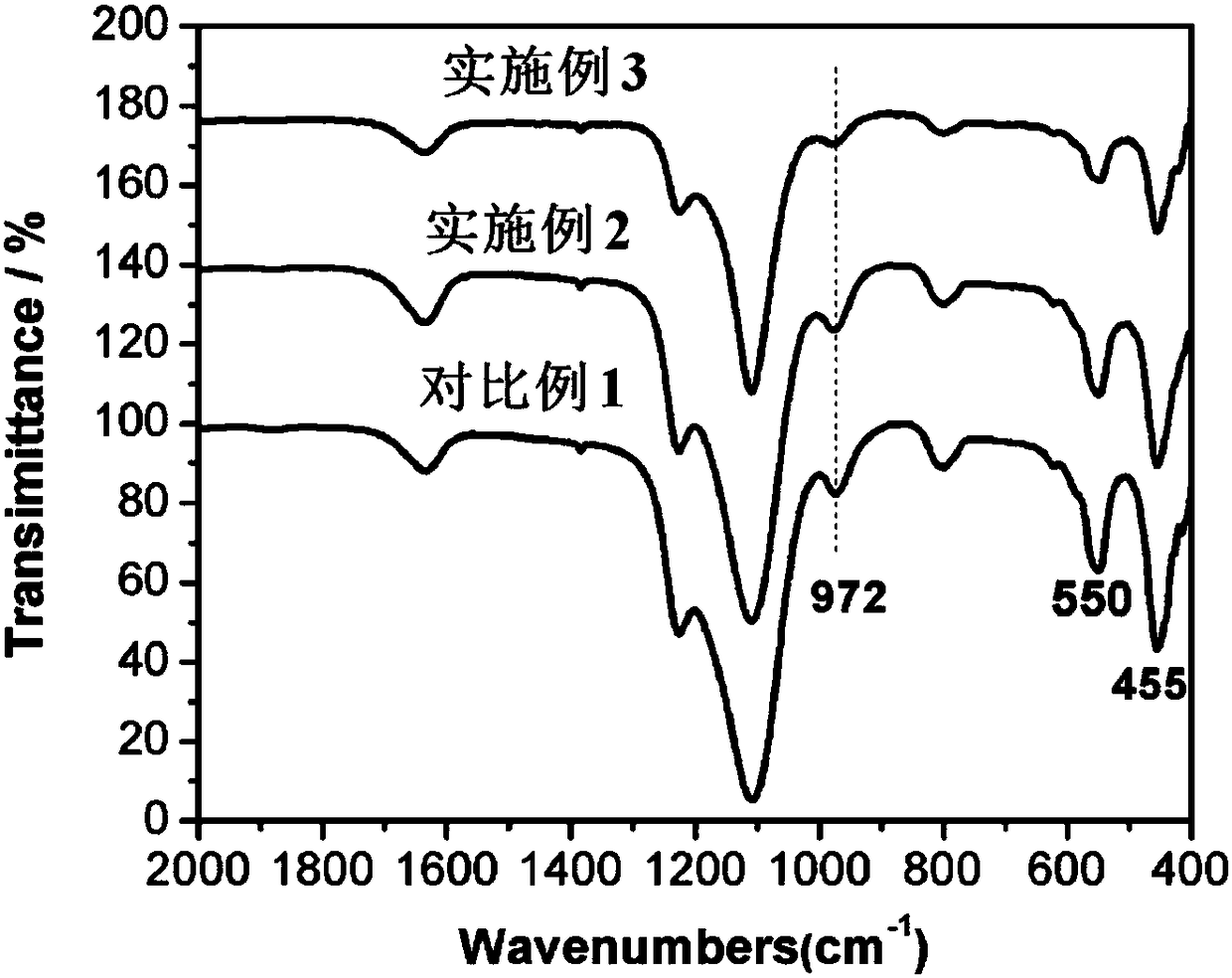

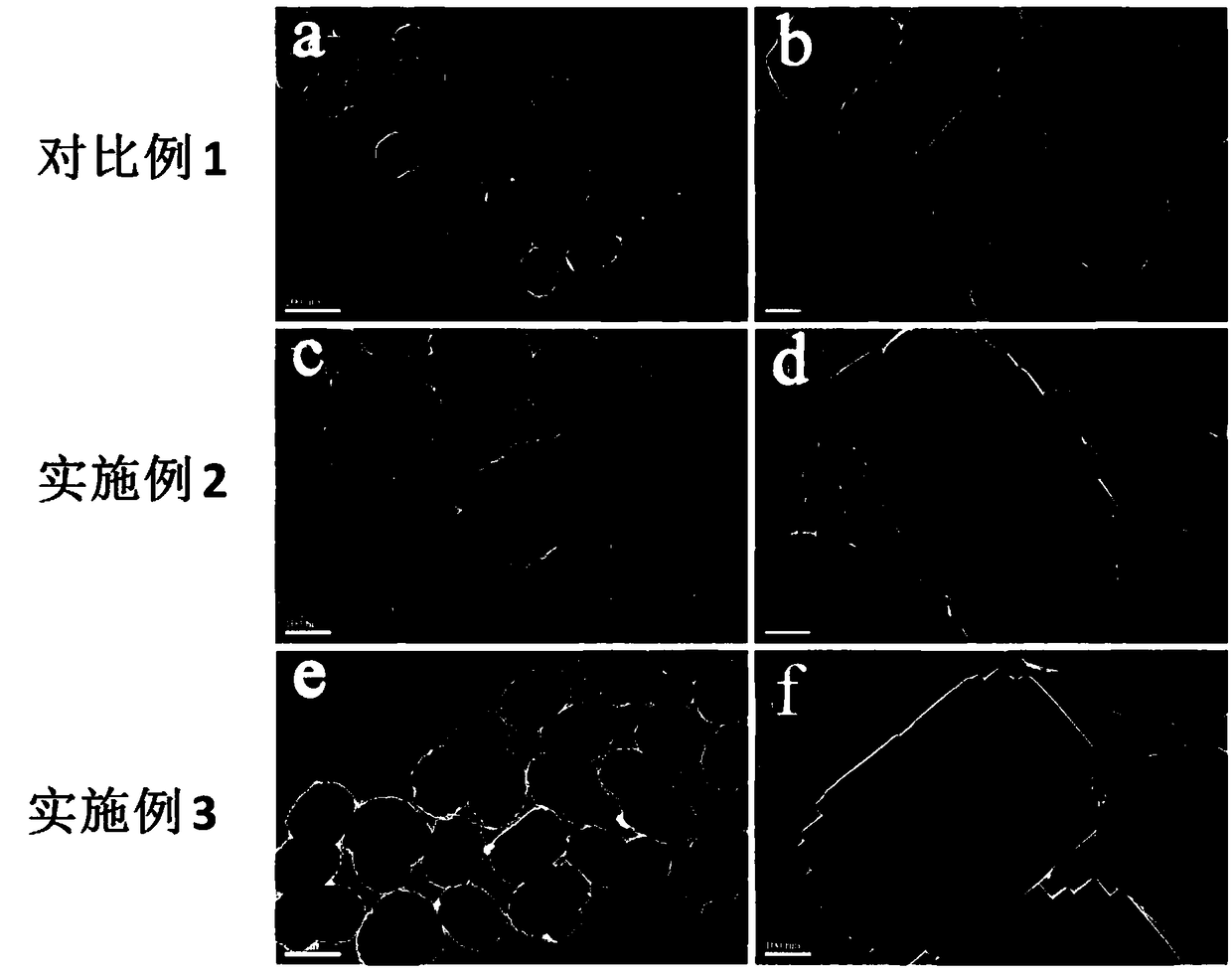

[0035] figure 1 It is the XRD spectrum of the titanium-silicon molecular sieve T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com