Fiber-reinforced lined composite pipe, and manufacturing method and device therefor

A fiber-reinforced and manufacturing method technology is applied in the field of fiber-reinforced lined composite pipes and their manufacturing, which can solve the problems of inability to produce large diameters, unguaranteed quality, low efficiency, etc., and achieve the advantages of saving raw materials, high production costs and reducing processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

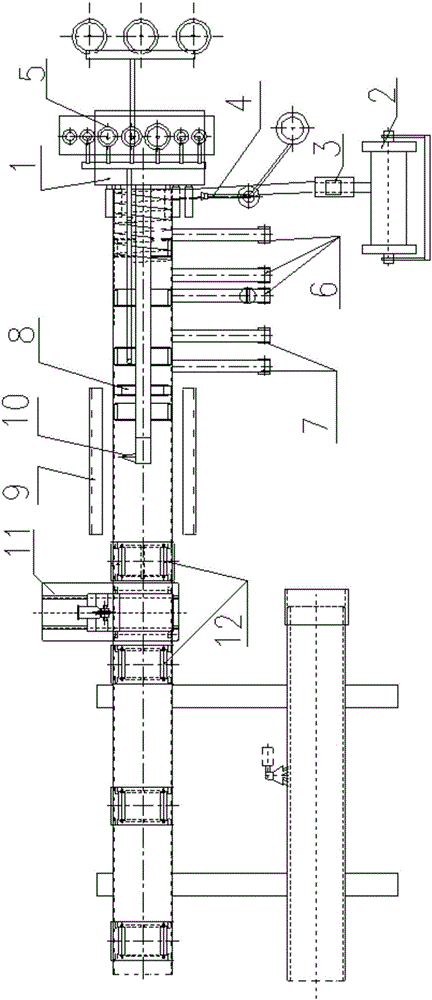

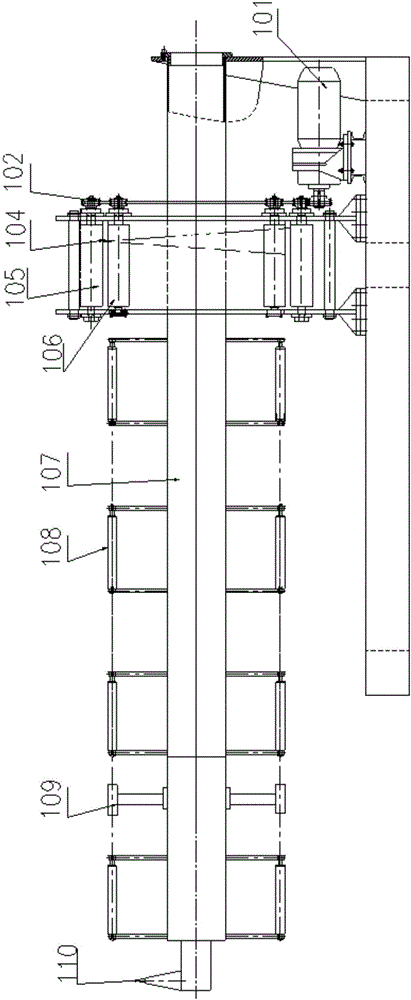

[0038] Such as Figure 4 Shown is a flow chart of the method for manufacturing a fiber-reinforced lining composite pipe provided by the present invention. Figure 4 It can be seen that the method of the present invention includes the following steps:

[0039] Continuously winding the strip to form a lined pipe with increasing length;

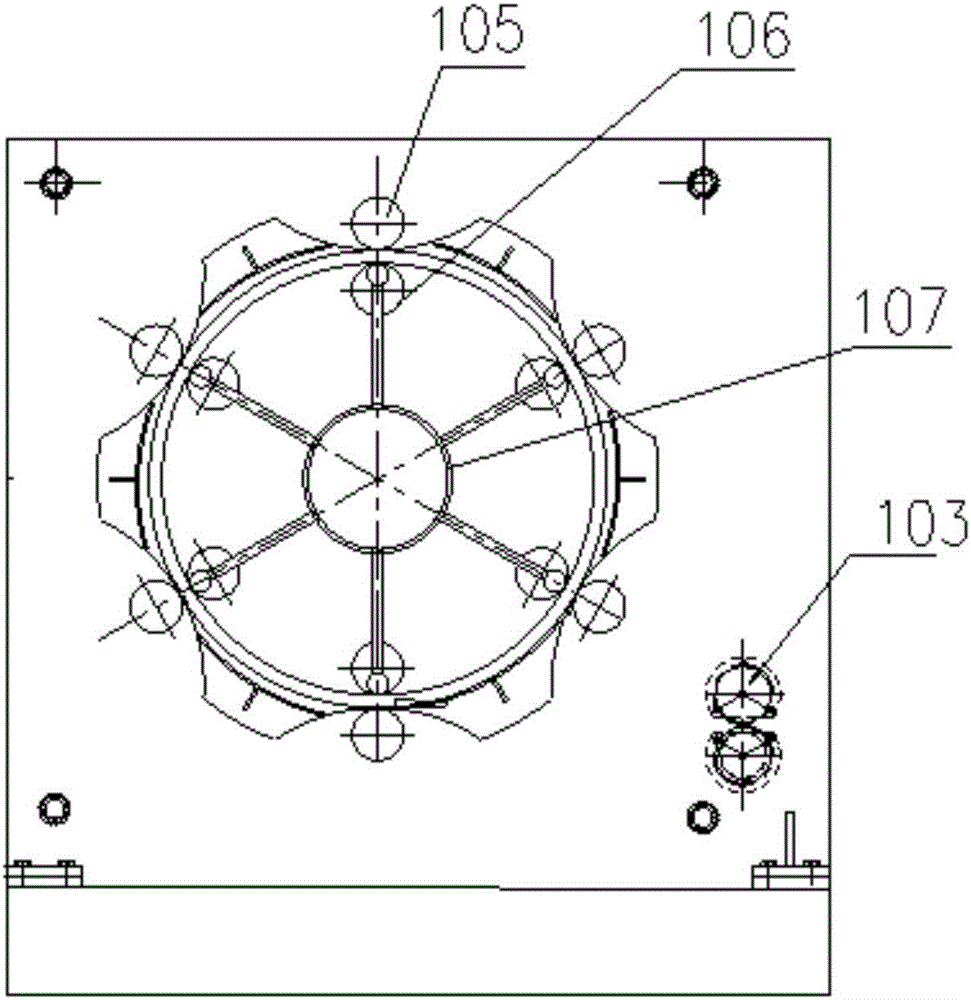

[0040] When forming the lining pipe with increasing length, the lining pipe is used as the internal support, and the fiber-reinforced material is simultaneously wound outside the lining pipe to form a reinforcement layer on the outer surface of the lining pipe;

[0041] While forming the reinforcement layer on the outer surface of the inner liner pipe, simultaneously wrap the protective decoration material outside the reinforcement layer to form a protective decoration layer on the outer surface of the reinforcement layer, so that the inner liner pipe is processed into a composite pipe;

[0042] After the composite pipe is formed, the composite pipe is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com