Battery feeding mechanism and full-automatic ring cutting machine provided with battery feeding mechanism

A battery and tray technology, applied in manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problems of heavy smoke in the workshop, inability to seal, poor suction effect, etc., achieve easy waste management, improve processing speed, and process speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

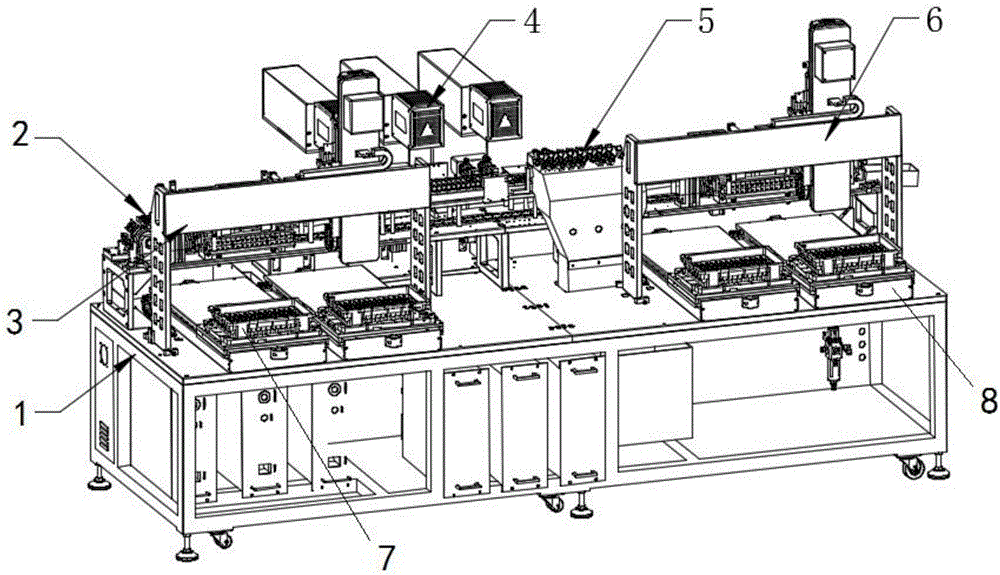

[0054] Figure 3 to Figure 10 A specific embodiment of the fully automatic ring cutting machine of the present invention is shown, which is used to cut off the heat-shrinkable tube of the corresponding part of the cylindrical battery A to expose the negative metal shell of the battery, So that the negative terminal of the battery can be inserted into the spring piece installed in the plastic clamp to realize contact and conduction. The fully automatic ring cutting machine includes a frame 1, which is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com