A Microparticle Separator Based on Negative Magnetophoresis Technology

A technology of microparticles and sorters, which is applied in the field of microfluidic systems, can solve the problems of poor sorting efficiency and difficulty in adapting the sorter to high-precision sorting of 1-20 micron particles, so as to ensure the sorting accuracy and avoid The integration of heater and control system ensures the effect of sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

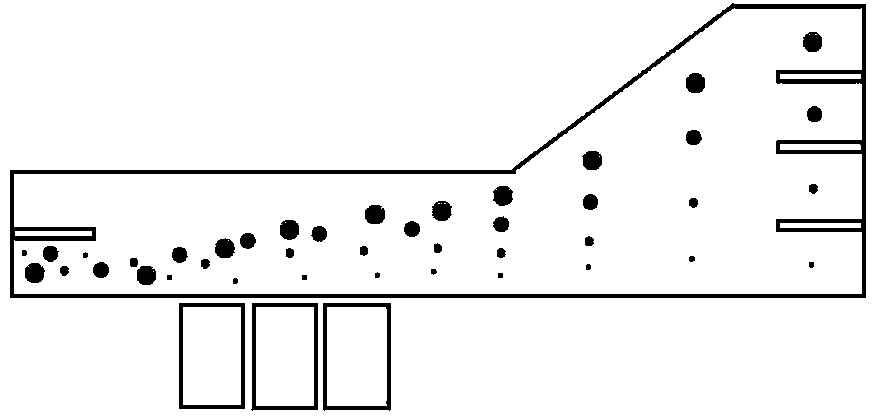

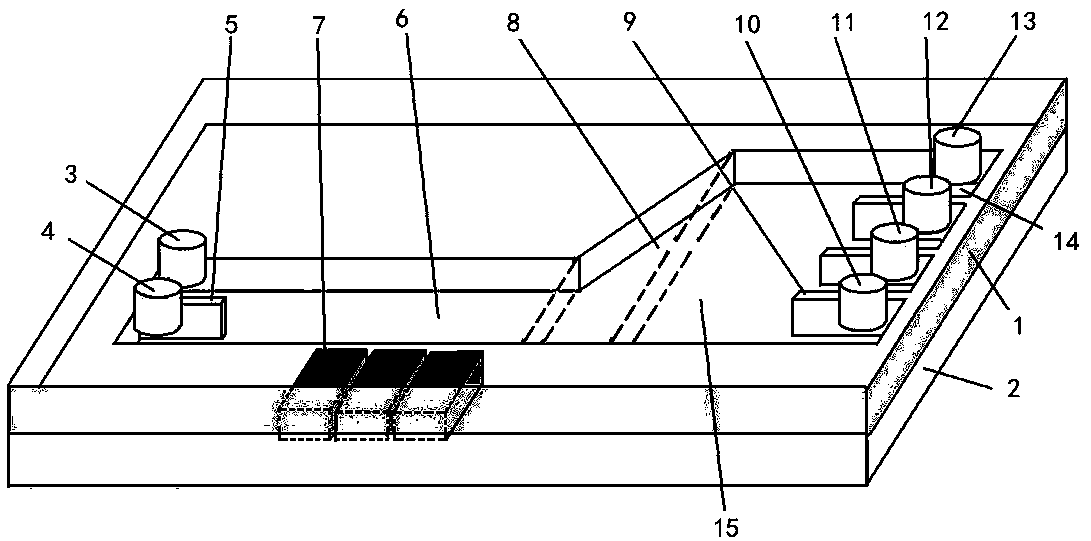

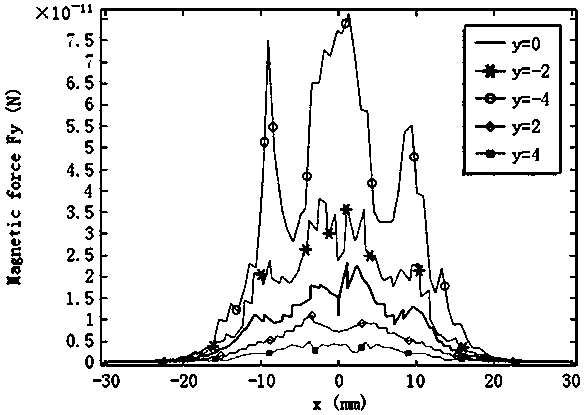

[0028] Example 1, assuming that the magnetic fluid containing 3, 7, and 15 micron particles is introduced at the inlet 2, and the particle density is 1055 kg / m 3 , the entrance speed is 1-5mm / s, sorting after entering the sorting channel with a height of 600 microns, three permanent magnets (maximum magnetic strength 0.57T), can produce 488, 155, 25 microns in the straight channel part The lateral migration distance is derived at exit 10, exit 2 11 and exit 4 13 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com