Electric hot water bag

An electric hot water bottle and electric heating wire mesh technology are applied in the directions of heating appliances for treatment, cooling appliances for treatment, contraceptives, etc., which can solve the problem that the PVC film cannot be shaped, the position of the electric heating wire mesh is not fixed, and the welding technology High requirements and other problems, to achieve the effect of strong plasticity, low clamping technology requirements, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

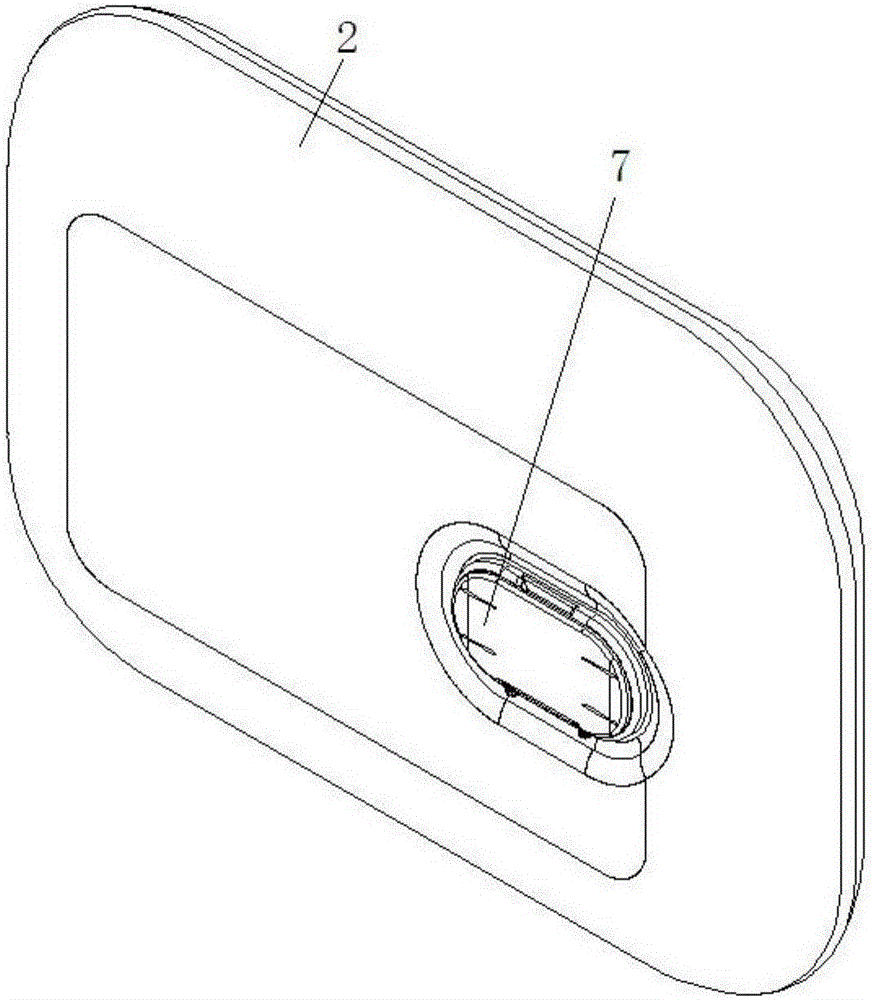

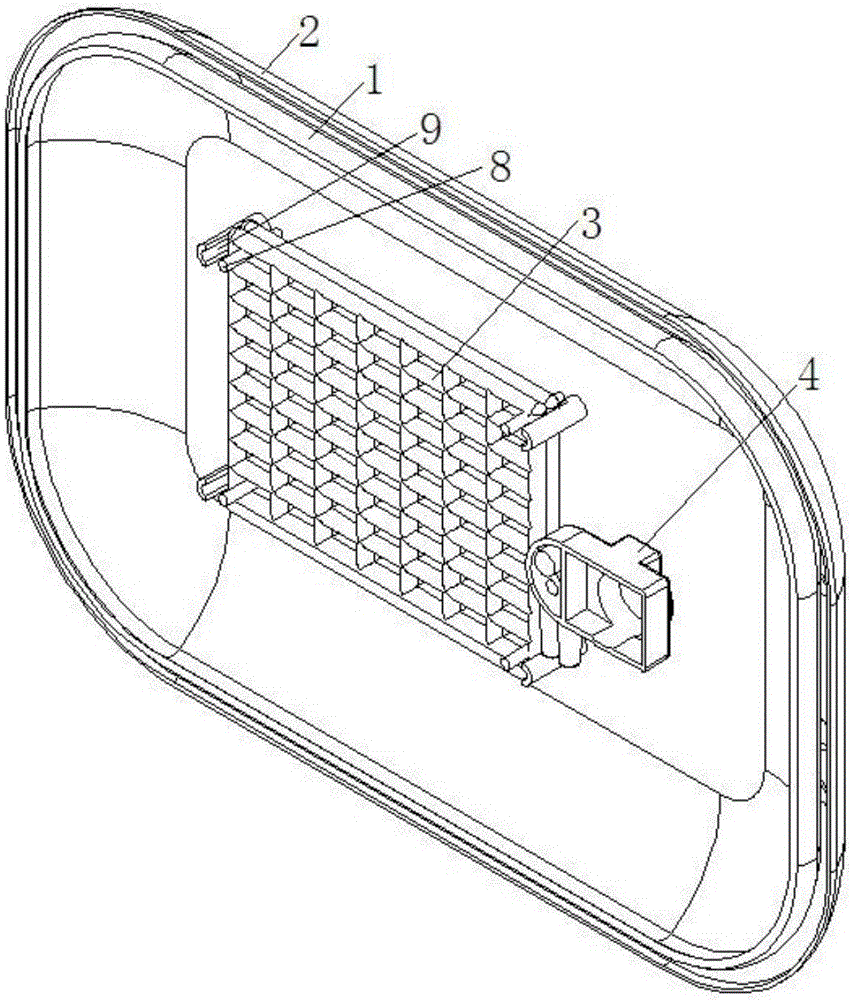

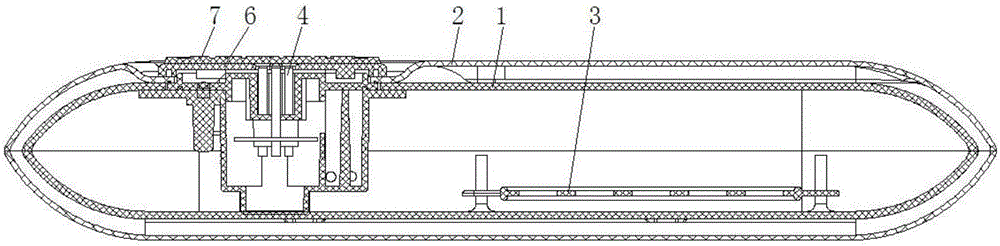

[0036] See Figure 1~5 , an electric hot water bag of the present invention, its overall shape is square, with an inner tank 1 for filling liquid, a shell 2 wrapped outside the inner tank 1, an electric heating wire mesh 3 distributed in the inner tank 1 and installed inside Socket 4 in line 1. Both the inner tank 1 and the outer shell 2 are injection molded from soft materials, and a closed air interlayer is formed between the inner tank 1 and the outer shell 2. The inner tank 1 and the outer shell 2 are respectively assembled by upper and lower shells. The peripheries of the upper and lower shells are assembled with each other by a welding process, and the peripheries of the upper and lower shells of the shell 2 are joined together by a welding process or an adhesive process or a buckle connection process. The shell 2 has a variety of splicing processes and strong operability. Low production cost.

[0037] See figure 2 and Figure 7 , the heating wire mesh 3 has a squar...

Embodiment 2

[0054] See Figure 10 and Figure 11 , the upper shell of the outer shell 2 and the upper shell of the inner tank 1 are connected to each other through several buckle parts 5, and the lower shell of the outer shell 2 and the lower shell of the inner tank 1 are also connected by several snap fasteners. The fasteners 5 are snapped together.

[0055] The buckle 5 is made of soft material, and the buckle 5 and the shell 2 are integrally injection molded, the injection molding process steps of the buckle 5 and the shell 2 are simple, and the yield is high; the head 5-1 of the buckle 5 It is pressed into the groove 1-1 at the corresponding position on the liner 1, the operation is simple, the technical requirements for the clamping connection are low, and the qualified rate is high.

[0056] Alternatively, the buckle 5 is made of a hard material, and the buckle 5 and the shell 2 are injection molded respectively, and the tail of the buckle 5 is provided with a through hole 2 5-2 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com