Method for preparing slow release-type tebuthiuron granular herbicide

A herbicide and slow-release technology, which is applied in the field of preparation of slow-release buthilone herbicide granules, can solve the problems of adverse environmental impact, long half-life, polluted soil surface water and groundwater, etc., and achieves reduction of phytotoxicity and storage and transportation costs Low, safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

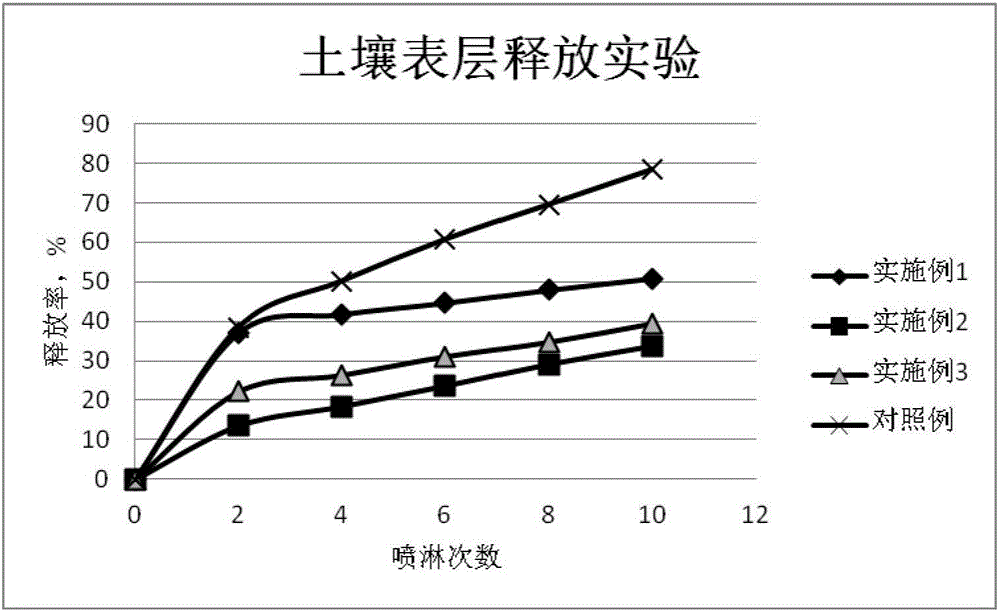

Embodiment 1

[0026] Take 200g of the original drug of buthiuron, dissolve it in 1L of dichloromethane, and prepare a solution of buthiuron in dichloromethane with a concentration of buthiuron of 200g / L; take 350g of expanded vermiculite and 50g of zeolite, and crush them into mixed carrier powder of 20-100 mesh ; Add the mixed carrier powder to the tetrathhiuron dichloromethane solution, stir in a closed reaction vessel at room temperature for 24 hours, and obtain the mixed solution of the tetrathhiuron mixed carrier powder; add 8 g of sodium silicate to the mixed solution of the tetrathhiuron-carrier powder, and continue to stir for 1 hour until mixed evenly; the mixed solution of tetrathhiuron-carrier powder after being uniformly mixed with sodium silicate is subjected to the first vacuum distillation until there is no obvious liquid residue, and passed through a 18-24 mesh sieve to obtain tetrabuthiuron-carrier powder particles; tetrathhiuron-carrier The powder granules were dried for th...

Embodiment 2

[0028] Take 60g of the original drug of buthiuron, dissolve it in 1L of acetone, and prepare a solution of buthiuron in acetone with a concentration of buthiuron of 60g / L; take 540g of expanded vermiculite and 60g of zeolite, and grind them into 100-200 mesh mixed carrier powder; mix the mixed carrier powder Add to the tetrathhiuron-acetone solution, stir in a closed reaction container at room temperature for 10 hours to obtain the tetrathhiuron-mixed carrier powder mixture; add 10 g of hydroxypropyl cellulose to the tetrathhiuron-carrier powder mixture, and continue to stir for 6 hours until the mixture is uniform; After being evenly mixed with hydroxypropyl cellulose, the tetrathhiuron-carrier powder mixture was distilled under reduced pressure for the first time until there was no obvious liquid residue, and passed through a 18-24 mesh sieve to obtain tetrathhiuron-carrier powder particles; The organic solvent was removed by drying under reduced pressure for the second time ...

Embodiment 3

[0030] Take 105g of the original drug of buthiuron, dissolve it in 1L of methanol, and prepare a buthiuron methanol solution with a concentration of buthiuron of 105g / L; take 570g of expanded vermiculite and 30g of zeolite, and pulverize them into a mixed carrier powder of 200-325 meshes; mix the carrier powder Add the tetrathhiuron methanol solution, and stir in a closed reaction vessel at normal temperature for 12 hours to obtain the tetrathhiuron-mixed carrier powder mixture; add 12 g of microcrystalline cellulose to the tetrathhiuron-carrier powder mixture, and continue to stir for 5 hours until the mixture is uniform; After the microcrystalline cellulose is evenly mixed, the tetrathhiuron-carrier powder mixed solution is subjected to the first vacuum distillation until no obvious liquid remains, and passed through a 18-24 mesh sieve to obtain the tetrathhiuron-carrier powder particles; the tetrathhiuron-carrier powder particles are subjected to the second The organic solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com