Stator iron core, stator, motor and preparation method for stator iron core

A stator core and iron core technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problem of large cogging torque, etc., and achieve the effect of low cogging torque and high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

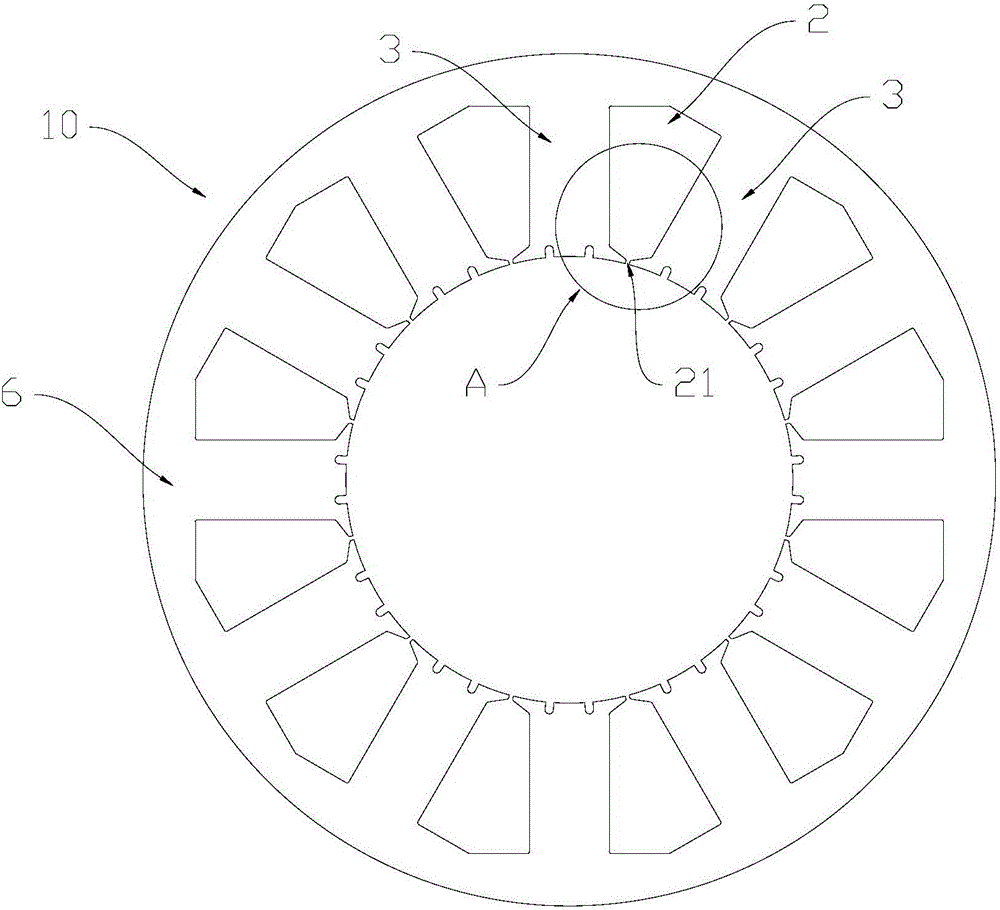

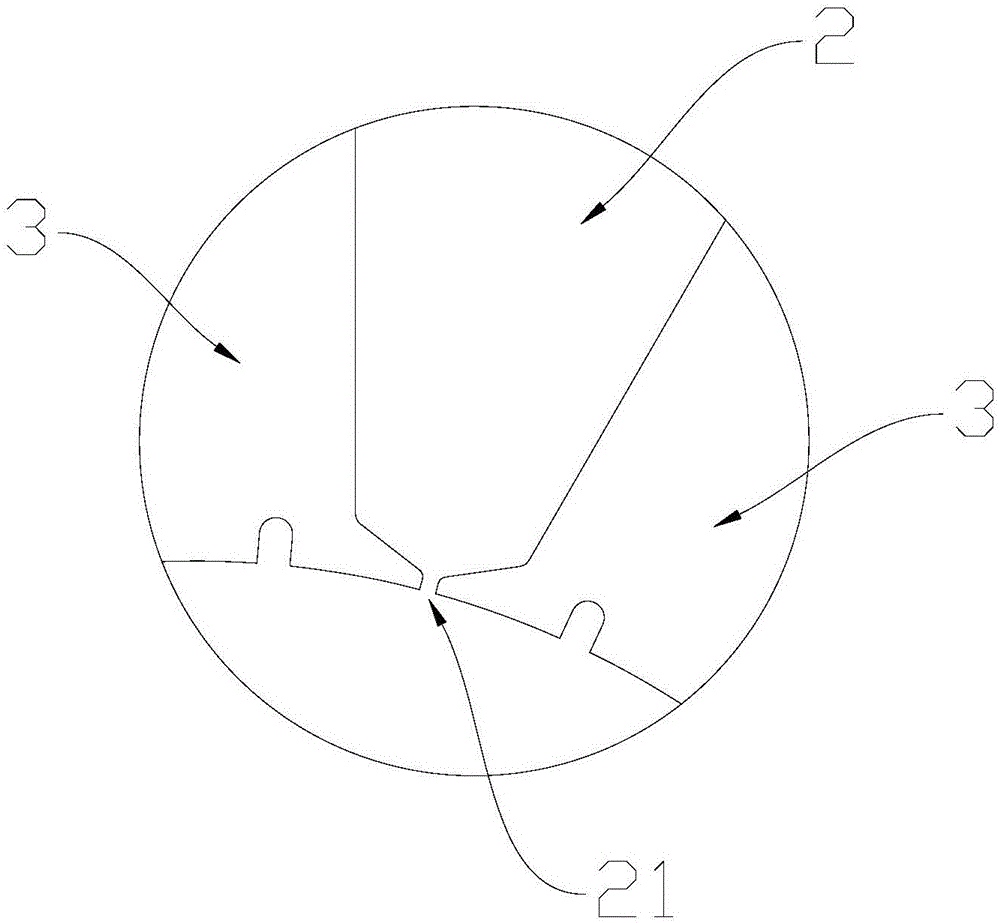

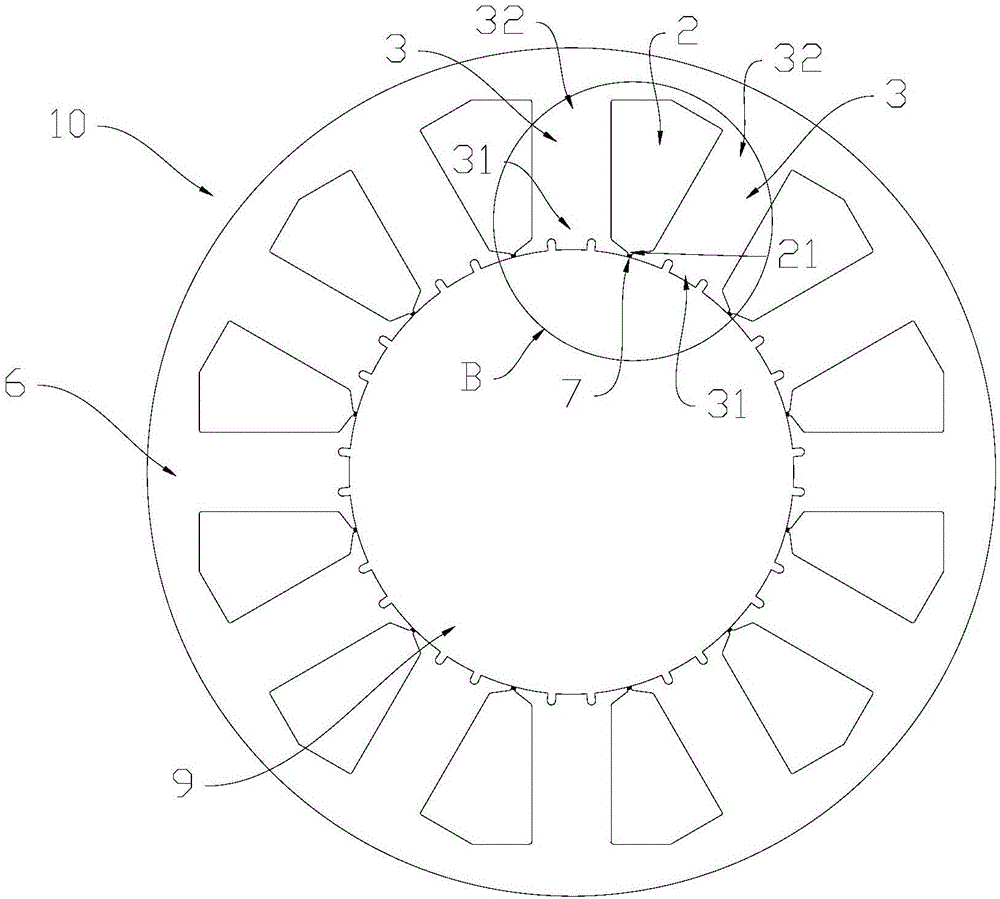

[0036] refer to Figure 3 to Figure 6 As shown, the stator core 10 according to the present invention includes a body 1 and a plurality of stator slots 2 arranged on the body 1 . A plurality of said stator slots 2 are arranged along the circumferential direction. Each of said stator slots 2 has a notch 21 . A magnetic conduction part is provided at the notch 21 of the stator slot 2 .

[0037] The magnetically permeable part can reduce or even close the notch 21 of the stator slot 2, so that even the magnetic permeability of the magnetic field at the notch 21 can be consistent with that of the stator teeth 3, thereby reducing the cogging torque. For example, through simulation calculations, refer to Figure 7 and Figure 8 Shown, under the same test condition, the cogging torque value of the servomotor in the prior art is 139.64mN. Part) the cogging t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com