Motor

A technology of motors and rotors, applied in the field of motors, can solve problems such as difficult formation of magnetic circuits, and achieve the effect of reducing cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0036] (The overall structure of the motor)

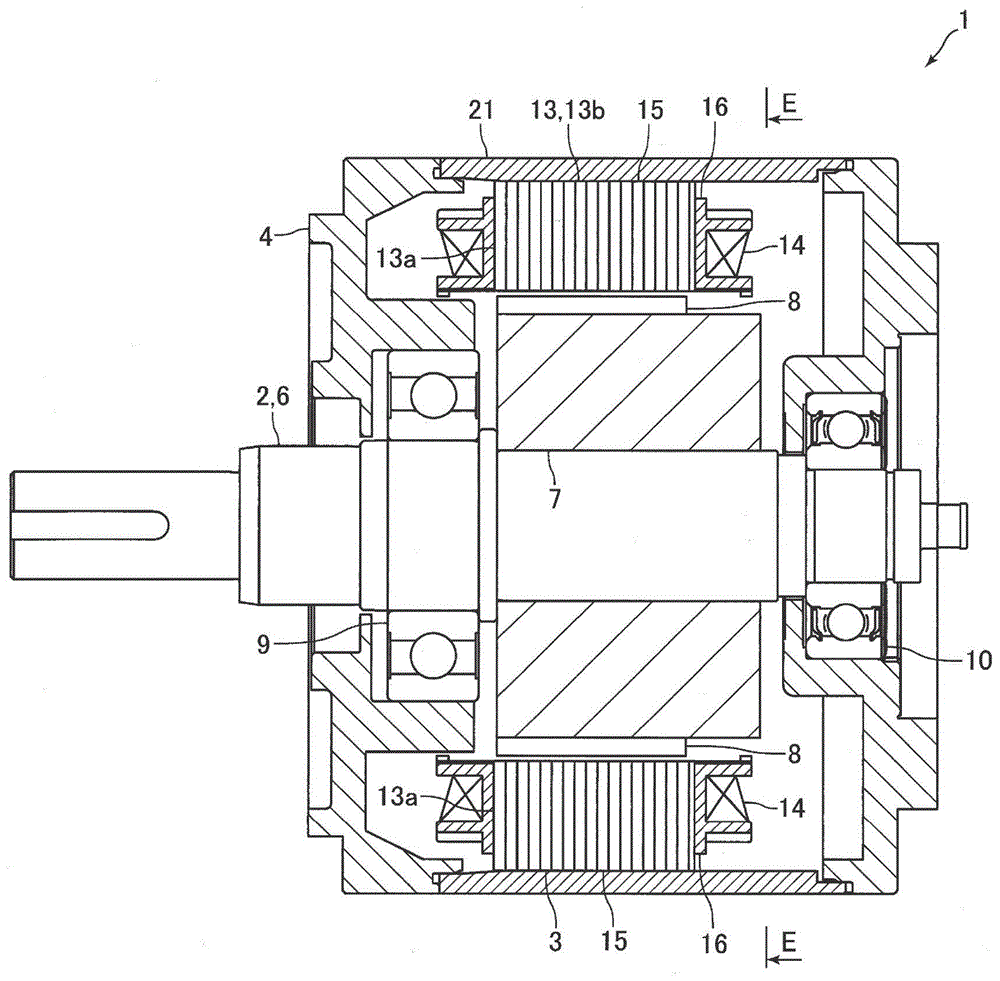

[0037] figure 1 It is a cross-sectional view of the motor 1 according to the embodiment of the present invention. figure 2 From figure 1 A diagram of the rotor 2 and the stator 3 shown in the E-E direction. image 3 Yes figure 2 A plan view of the permanent magnet 8 and the split core 15 shown.

[0038] The motor 1 of the present embodiment is an inner rotor type motor, and the outer diameter of the motor 1 is about 130 mm. Also, the capacity of the motor 1 is 850W to 2kW. like figure 1 As shown, the motor 1 includes a rotor 2 , a stator 3 arranged on the outer peripheral side (radial outer side) of the rotor 2 , and a motor case 4 . In the following description, the radial direction of the motor 1 (that is, the radial direction of the rotor 2 and the radial direction of the stator 3 ) is referred to as the “radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com