Package method of diode pumping laser module

A diode module, pump laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of unguaranteed distribution uniformity, inconvenient operation, low packaging efficiency, etc., achieve simple and efficient packaging steps, and improve distribution. uniformity, the effect of improving pump performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

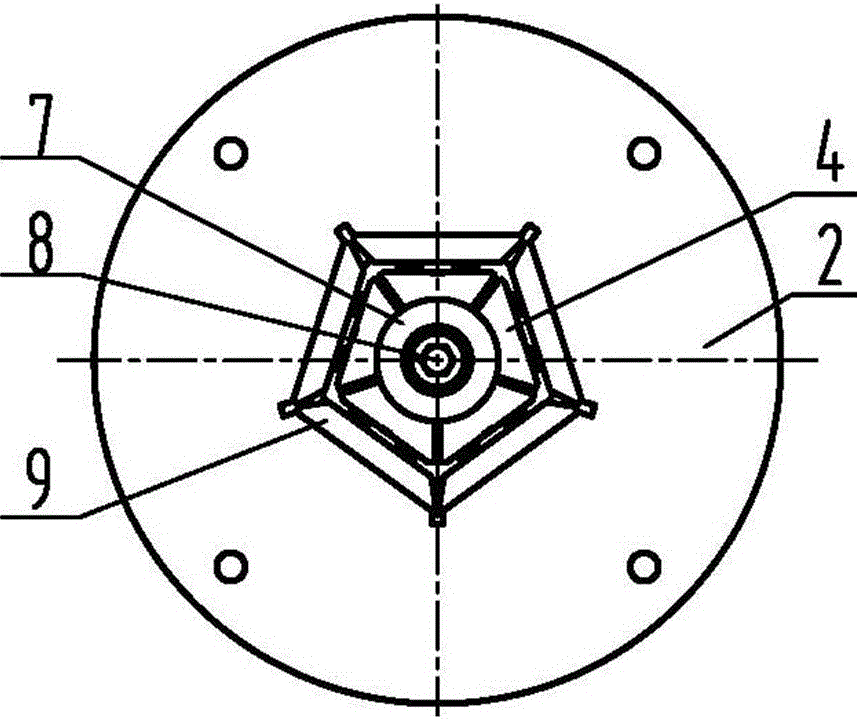

[0056] 1a. Install the cooler 2 on the upper surface of the installation base 1;

[0057] 1b. Bind the device entity 4 into a regular pentagon with O-ring 5, N=5;

[0058]1c. Install the upper pressing block 7 and the lower pressing block 3 in the inner cavity of the device entity 4, and then tighten the long screws 8 to fix the device entity 4, the upper pressing block 7 and the lower pressing block 3 into a device module;

[0059] 1d. Insert the device module vertically into the cooler 2 and the installation base 1. The cylinder at the lower end of the lower pressure block 3 is fitted and positioned with the positioning hole at the bottom of the installation base 1. The gap L1 and gap L2 meet L1-L2= 2mm;

[0060] 1e. Place five diode modules 9 on the upper surfaces of the corresponding regular pentagonal bosses;

[0061] 1f. Continue to tighten the long screw 8, the upper pressing block 7 and the lower pressing block 3 are close to each other, and the five identical triang...

Embodiment 2

[0066] Embodiment 2 is basically the same as Embodiment 1, the main difference is that N=7, L1-L2=2.5mm, and a heptagonal diode-pumped laser module is obtained.

Embodiment 3

[0068] Embodiment 3 is basically the same as Embodiment 1, the main difference is that N=9, L1-L2=3mm, and a nonagonal diode-pumped laser module is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com