Transformer capable of controlling magnetic flux leakage

A transformer and flux leakage technology, applied in the field of transformer manufacturing, can solve problems such as overheating of metal structural parts, overheating of transformer oil tank connecting bolts, etc., and achieve the effect of solving local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

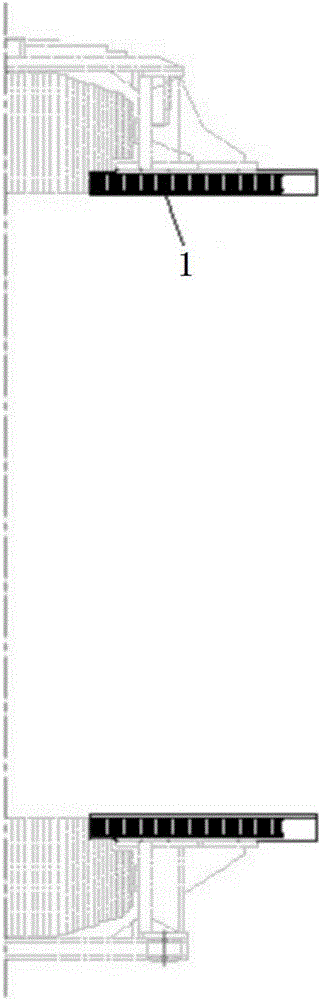

[0022] Such as figure 1 As mentioned above, the lobe-shaped magnetic shield 1 is arranged on the body of the transformer and in the iron yoke pad at the lower end. The lobe-shaped magnetic shield 1 is divided into three thicknesses of 50mm, 65mm and 80mm according to the capacity of the transformer.

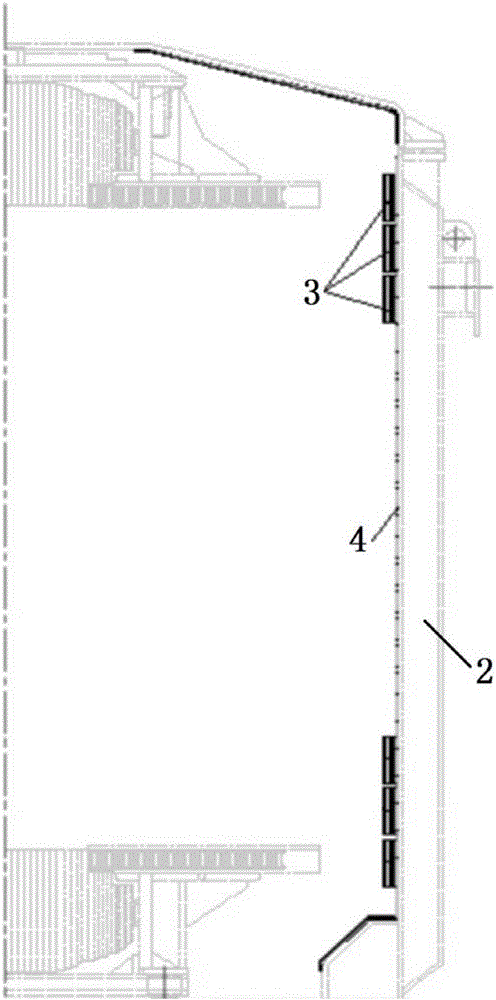

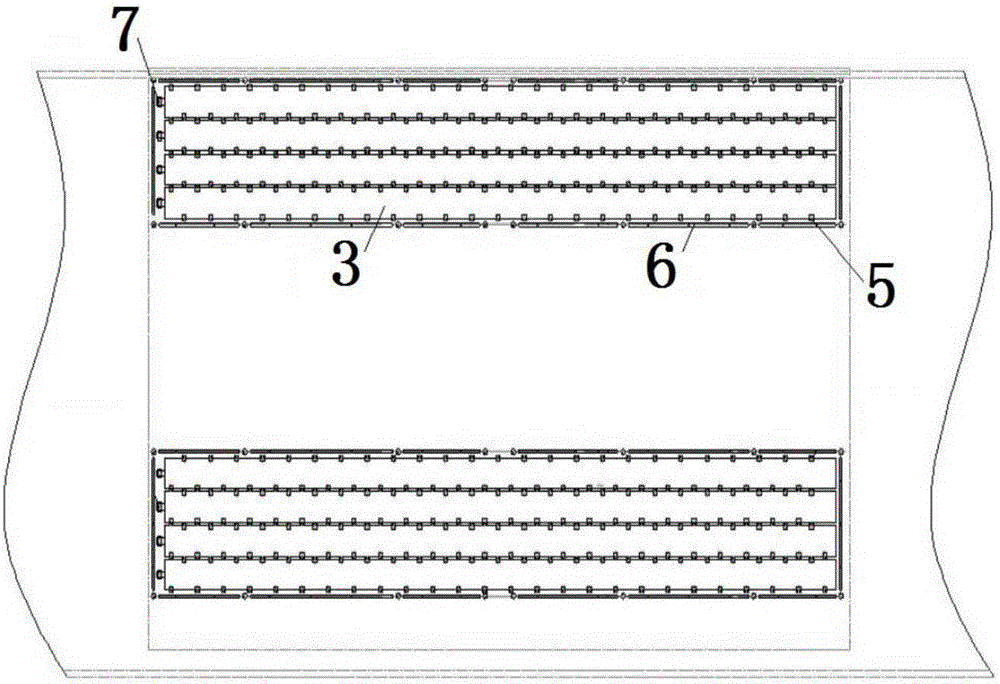

[0023] Such as figure 2 — Figure 4 As mentioned above, the 6mm copper shielding 4 arranged on the inner wall of the transformer oil tank 2 and the strip-shaped magnetic shielding composed of at least one magnetic shielding strip 3 laid on the upper and lower ends of the copper shielding 4 respectively, the magnetic shielding strip 3 passes through the curved plates 5 around it Lay on the surface of the copper shielding 4, the copper shielding 4 is provided with an opening, the bent plate 5 passes through the opening and is welded on the inner wall of the fuel tank, the magnetic shielding strip 3 is wrapped from the inside to the outside through the 0.5mm paper slot 9 and the 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com