Manufacturing method of light guide plate

A manufacturing method and technology of light guide plates, applied in optics, light guides, optical components, etc., can solve the problems of increasing time and cost, achieve good manufacturing accuracy, save product development time, and save product development time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the accompanying drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

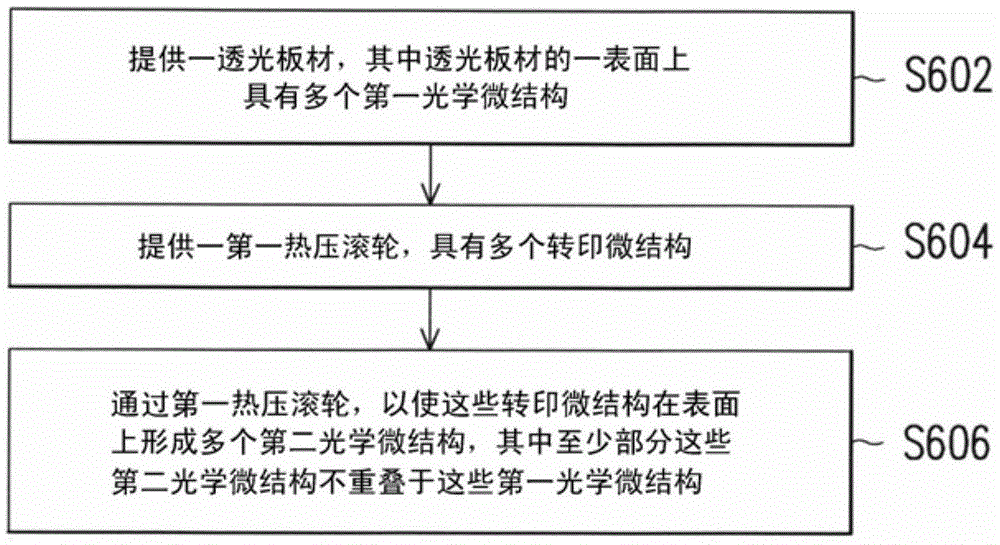

[0026] figure 1 It is a flowchart of a manufacturing method of a light guide plate according to an embodiment of the present invention. Figure 2A to Figure 2D is showing figure 1 Schematic diagram of the steps in the fabrication method. Please refer to Figure 1 to Figure 2D , first, provide Figure 2A A light-transmitting plate 110 is shown, wherein there are a plurality of first optical microstructures 112 on a surface 110a of the light-transmitting plate 110 (step S602), the thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com