Method for determining humus and component contents thereof in sludge compost

A humus and composting technology, applied in the field of humus determination, can solve the problems of incomplete extraction, long extraction cycle, and lack of standard specifications for humus, and achieve the effects of overcoming incomplete extraction, improving measurement accuracy, and simple and quick determination methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

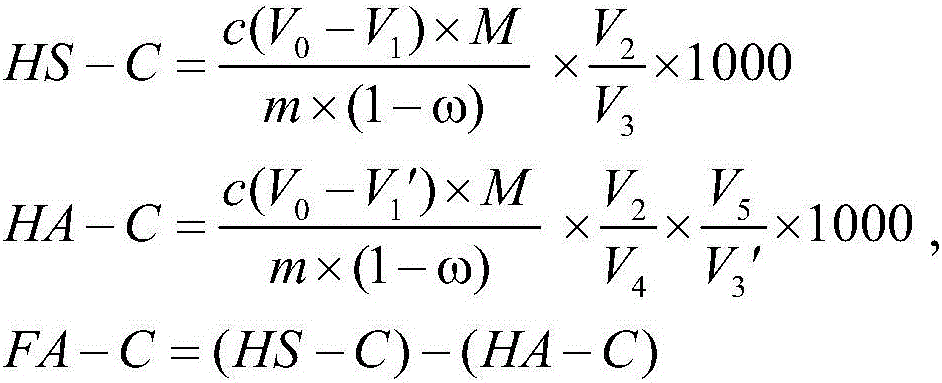

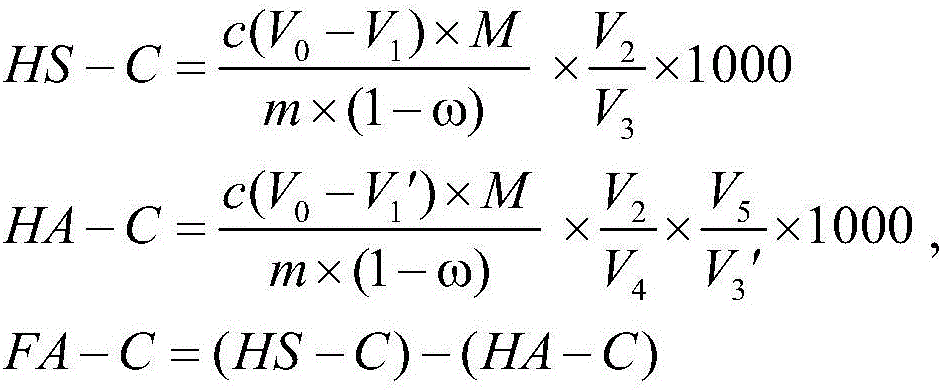

Method used

Image

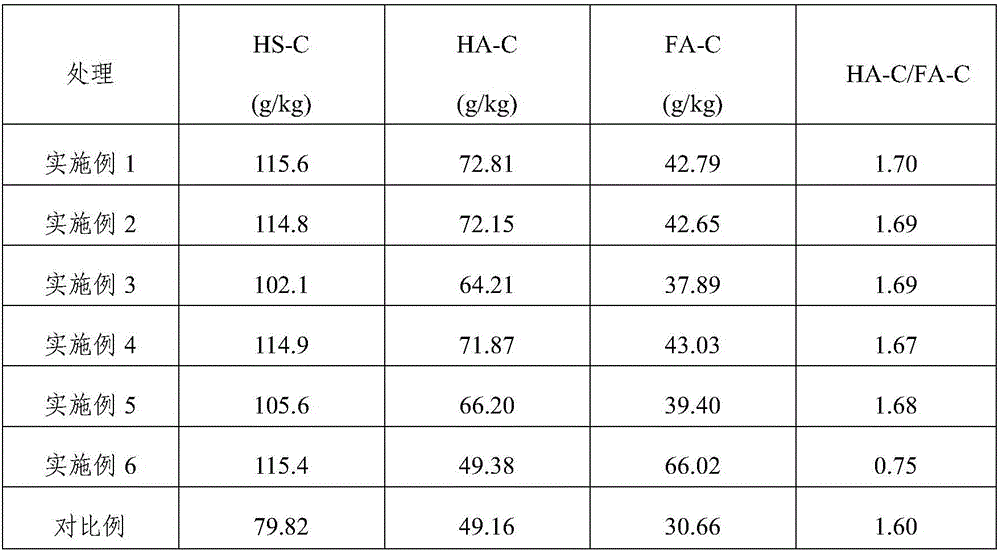

Examples

Embodiment 1

[0045] The present embodiment provides a method for measuring humus and component content thereof in sludge compost, which comprises the following steps:

[0046] S1, air-dry and pulverize the sludge compost, pass through a 100-mesh sieve to obtain a sludge compost sample, and then measure the water content ω of the sludge compost sample;

[0047] S2, take 5g of the sludge compost sample described in step S1, add 50mL extract solution therein, carry out 30min boiling water bath after mixing, add deionized water after cooling to 200mL, and then under the centrifugal speed of 4000r / min Centrifugal 10min, gained supernatant is humic substance solution, and volume is V 2 , from which the volumes V are taken, respectively 3 and V 4 The first humic substance solution and the second humic substance solution; Another equivalent amount of the leach solution is carried out in the boiling water bath, and then the volume is V 3 and V 4 The first blank sample and the second blank sampl...

Embodiment 2

[0065] This embodiment is basically the same as Embodiment 1, the difference is only in:

[0066] The time of the boiling water bath described in step S2 is 25min;

[0067] The volume of the first humic substance solution is 8mL;

[0068] In step S3, the pH value of the second humic substance solution is adjusted to 2.

Embodiment 3

[0070] This embodiment is basically the same as Embodiment 1, the difference is only in:

[0071] The time of the boiling water bath described in step S2 is 20min;

[0072] The volume of the first humic substance solution is 8mL;

[0073] The volume of the first humic acid solution is 15mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com