Constant temperature and constant humidity system device suitable for precision casting environment

A constant temperature and humidity, precision casting technology, applied in the field of precision casting, can solve problems such as uncontrollable accuracy of constant temperature and humidity machines, low humidity in the position of dehumidifiers, unstable reheating system, etc., so as to save transportation energy consumption and reduce The effect of dehumidification, temperature and humidity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

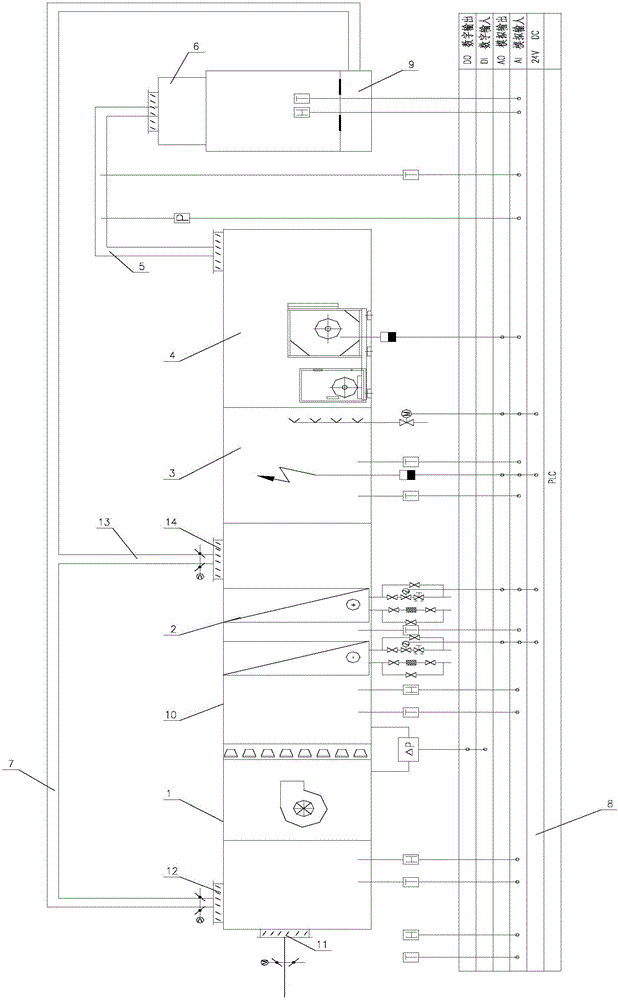

[0024] A precision casting (automobile grinding wheel pressurized) constant temperature and humidity shell workshop covers an area of 25 square meters, and the process requires a temperature of 21±1°C and a relative humidity of 60±3%. , The room dehumidification capacity is 15kg / h. The constant temperature system with dehumidification section is selected, and the constant temperature and humidity system device suitable for precision casting environment is adopted, and the designed air supply volume is 3000m 3 / h (traditional air volume needs to reach 8000m 3 / h), after dehumidification by the dehumidification device 1, the moisture content of the air is ≤4g / kg, after being processed by the cooling load processing device 2, the temperature drops by 19°C, and then enters the temperature and humidity fine-tuning device 3, and the temperature and humidity PLC controller 8 according to the indoor temperature and humidity The inspection is compared with the value of the temperatu...

Embodiment 2

[0026] Precision casting (aircraft engine blades) constant temperature and humidity workshop covers an area of 160㎡, and the process requires a temperature of 24±1°C and a relative humidity of 40±3%. The humidity in the room is 45kg / h, and a precision casting constant temperature and humidity system and device are selected with a constant temperature system with a dehumidification section, and the design air supply volume is 10,000m 3 / h (traditional air volume needs to reach 25000m 3 / h), once the return air or fresh air is dehumidified by the dehumidification device 1, the moisture content is ≤4g / kg, and the dry air after dehumidification is cooled to 19°C by the cooling load processing device, and then enters the temperature and humidity fine-tuning device 3, and the temperature and humidity are controlled by PLC The device 8 compares the value of the temperature and humidity detection after the cooling load processing device 2 according to the inspection of the indoor te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com