System and method for increasing comprehensive heat energy utilization rate in hot-process phosphoric acid production process

A production process, the technology of thermal phosphoric acid, applied in the steam generation method using heat carrier, phosphoric acid, phosphorus oxyacid and other directions, can solve the problems such as the inability to generate greater economic benefits, the low efficiency of thermal energy utilization, and the inability to recover costs, etc. Achieve the effect of improving the comprehensive utilization rate of heat energy, increasing the steam production, and avoiding the high temperature of the tower wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

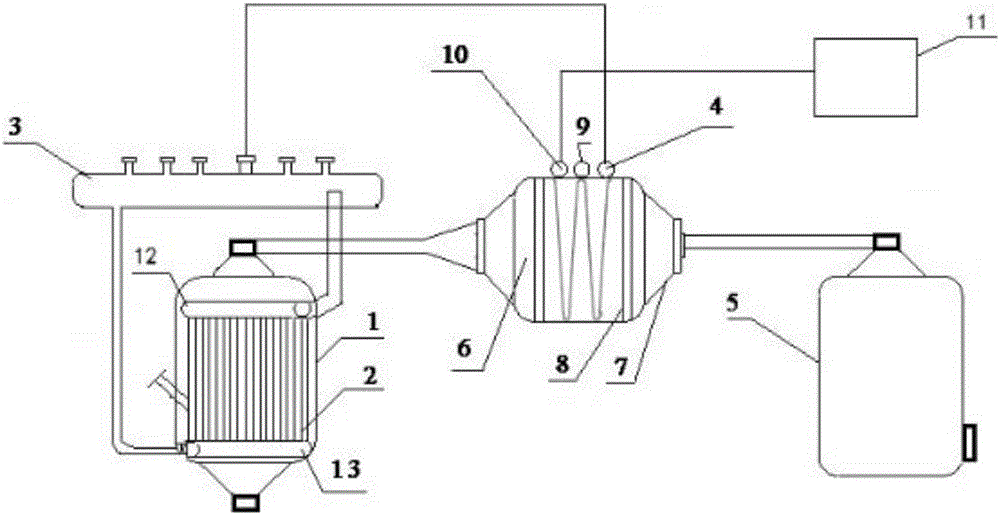

[0034] see figure 1As shown, the embodiment of the present invention provides a system for improving the comprehensive utilization rate of thermal energy in the production process of thermal phosphoric acid, including a reaction tower 1, a superheater 6, a hydration tower 5 and a steam turbine power generation device 11, a reaction tower 1, a superheater 6, The hydration towers 5 are connected in sequence, and the steam turbine power generation device 11 is connected with the superheater 6 .

[0035] The inside of the reaction tower 1 is provided with an upper header 12, a lower header 13 and a plurality of first heat exchange tubes 2, and the outside of the reaction tower 1 is provided with a steam drum 3, and the bottom of the steam drum 3 is provided with a water outlet, and its upper outer wall is provided with There is a steam inlet, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com