Intelligent maintenance system for concrete outer wall

A curing system and concrete technology, applied in the field of concrete, can solve the problems of low labor efficiency, large wall damage, and no effect of concrete temperature drop, and achieve the effects of saving labor costs, improving maintenance quality, and reducing cracking risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

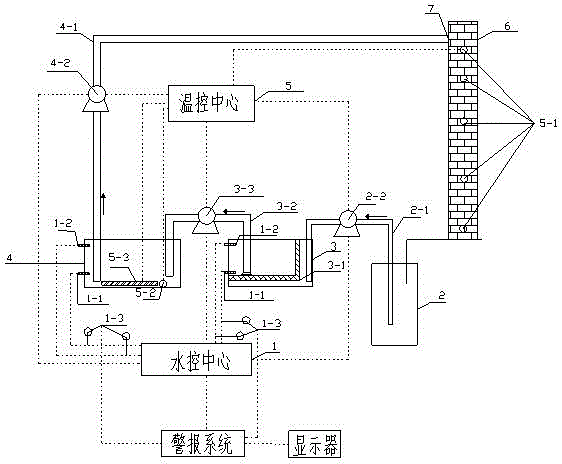

[0040] Such as figure 1 As shown, this embodiment provides an intelligent maintenance system for concrete exterior walls, including the external water source 2, water collection tank 3, heat preservation tank 4, intelligent water level system, intelligent temperature control system, alarm system and wall maintenance system. The external water source 2, water collection tank 3, and heat preservation tank 4 are connected to the concrete exterior wall 6 through the external water source outlet pipe 2-1, the water collection tank outlet pipe 3-2, and the heat preservation tank outlet pipe 4-1 in sequence. The water collection tank 3 is divided into a water inlet area and a water collection area, and a filtering device 3-1 is arranged between the water inlet area and the water collection area. The sump 3 is arranged under the ground, and the notch is flush with the ground.

[0041] The intelligent water level system includes a water control center 1, a flow controller, and a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com