X80 and below steel grade pipeline steel for deep-sea drilling marine riser and preparation method thereof

A technology for riser and pipeline steel, which is applied to pipeline steel below X80 steel grade, which requires uniform vertical and horizontal strength and dual hardness requirements. X80 pipeline steel and its manufacturing field can solve the problem of not mentioning the transverse tensile properties and longitudinal and transverse tensile strength. Uniformity, there is no mention of scour surface hardness requirements, etc., to achieve the effect of uniform vertical and horizontal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

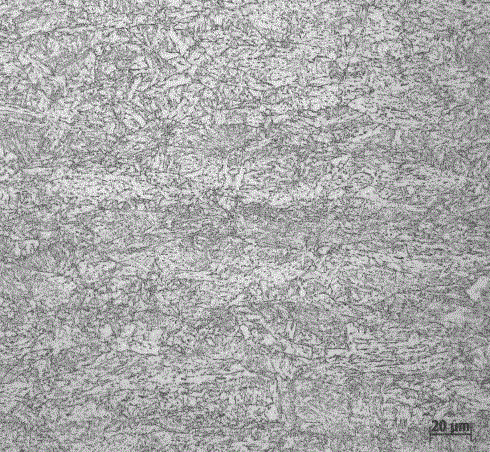

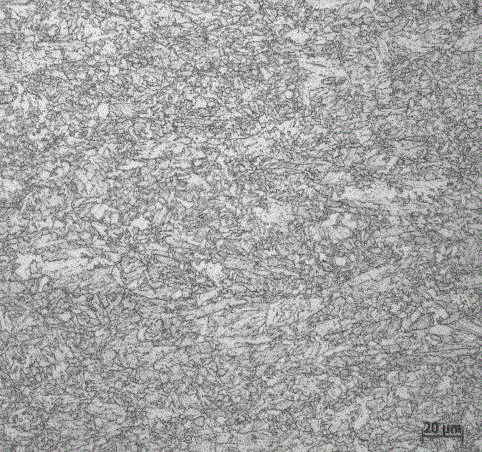

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

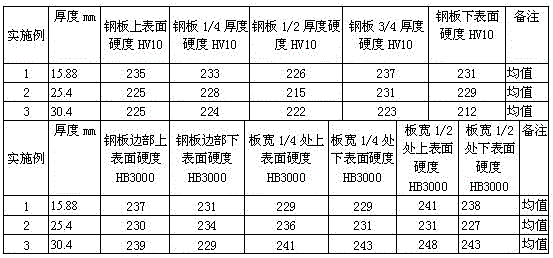

[0036] The smelting chemical composition of the pipeline steel for deep-sea drilling riser of each embodiment of the present invention is shown in Table 1 (wt%), and the rest is Fe and unavoidable impurity elements.

[0037] Table 1

[0038] Example C mn Si S P Nb Ti V Alt Mo+Cu+Ni+Cr B Ca 1 0.06 1.85 0.30 0.0005 0.008 0.03 0.015 0.06 0.028 ≤0.70 - ≤0.01 2 0.04 1.50 0.45 0.0005 0.009 0.025 0.018 0.05 0.030 ≤0.70 - ≤0.01 3 0.08 1.70 0.25 0.0015 0.007 0.04 0.021 0.02 0.035 ≤0.70 - ≤0.01

[0039] The corresponding technological process of the above-mentioned embodiment is converter or electric furnace smelting→external refining→continuous casting→slab reheating→specific TMCP process+air cooling to room temperature; deep desulfurization is carried out by feeding Ca wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com