Organic liquid mulch film and production method thereof

An organic liquid and mulch technology, applied in the fields of forestry, agricultural fertilizer and mulch, can solve the problems of low work efficiency, high manufacturing cost, residual fields, etc., and achieve the effects of low manufacturing cost, convenient transportation and simple structure

Inactive Publication Date: 2017-02-01

魏朝辉

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, in the known cultivation of crops and flowers, the mulch used is plastic mulch and inorganic chemical liquid mulch. Although plastic mulch has the advantages of increasing ground temperature, suppressing weeds, and reducing soil moisture evaporation, the disadvantage is that the mulch is During laying, the labor intensity of farmers is high, and the work efficiency is low, and the manufacturing cost is also high. It takes at least two people per mu to spend two to three days to complete the laying, including the mulching after laying, followed by this kind of Plastic mulch cannot be degraded, and if it is left in the field, it will cause soil pollution. After a few years, it will reduce the yield of crops and even affect the quality of crops. Although the liquid mulch synthesized by inorganic chemistry can achieve the function of plastic mulch, it still cannot be completely degraded and will still be damaged. The field remains, so the technology of organic liquid mulch film that can not only have heat preservation, water retention, degradability, fertility, and insecticidal functions has been plaguing the industry.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

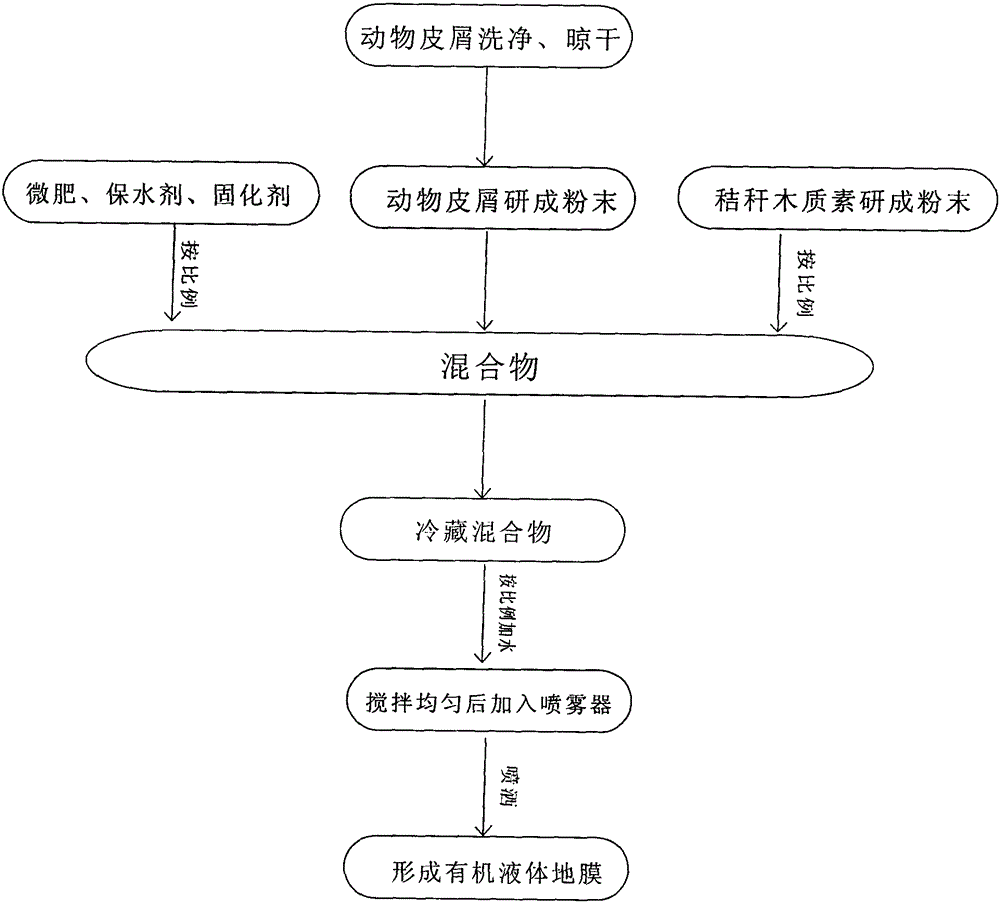

[0007] In the example, first wash the animal dander, boil it into a liquid gel, dry it into a solid state, and grind it into a powder. Add micro-fertilizer, insecticide, water-retaining agent, and curing agent in proportion, and stir evenly for 9 minutes. When making organic liquid mulch, take out the stirred mixture and mix it with tap water at normal temperature 10.6 times its weight. Liquid Mulch.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an organic liquid mulch film and a production method thereof. The organic liquid mulch film is produced through mixing 6 g of animal dander, 5 g of crop straw lignin, 0.11 g of a microelement fertilizer, 0.03 g of a pesticide, 0.09 g of a water retaining agent and 0.14 g of a curing agent according to a certain ratio. The production method comprises the following steps: washing the animal dander, boiling the animal dander to form liquid gel, airing the liquid gel to form solid gel, grinding the solid gel to form powder, screening the crop straw lignin, grinding the screened crop straw lignin to form powder, sequentially adding the microelement fertilizer, the pesticide, the water retaining agent and the curing agent in proportion, uniformly stirring for 9 min, preserving the above obtained stirring mixture in a refrigerator, taking the stirring mixture, mixing the stirring mixture with normal-temperature tap water with the weight 10.6 times the weight of the stirring mixture, uniformly stirring, and adding the obtained mixture solution into a sprayer to apply the solution in order to form the organic liquid mulch film.

Description

technical field [0001] The invention relates to the fields of forestry, agricultural fertilizers and plastic films, in particular to a liquid plastic film with organic fertilizers and a preparation method. Background technique [0002] At present, in the known cultivation of crops and flowers, the mulch used is plastic mulch and inorganic chemical liquid mulch. Although plastic mulch has the advantages of increasing ground temperature, suppressing weeds, and reducing soil moisture evaporation, the disadvantage is that the mulch is During laying, the labor intensity of farmers is high, and the work efficiency is low, and the manufacturing cost is also high. It takes at least two people per mu to spend two to three days to complete the laying, including the mulching after laying, followed by this kind of Plastic mulch cannot be degraded, and if it is left in the field, it will cause soil pollution. After a few years, it will reduce the yield of crops and even affect the qualit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K17/52A01G13/02C05G3/04C09K101/00C05G3/80

Inventor 魏朝辉

Owner 魏朝辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com