Resistive macromolecule humidity-sensitive material and preparation method thereof

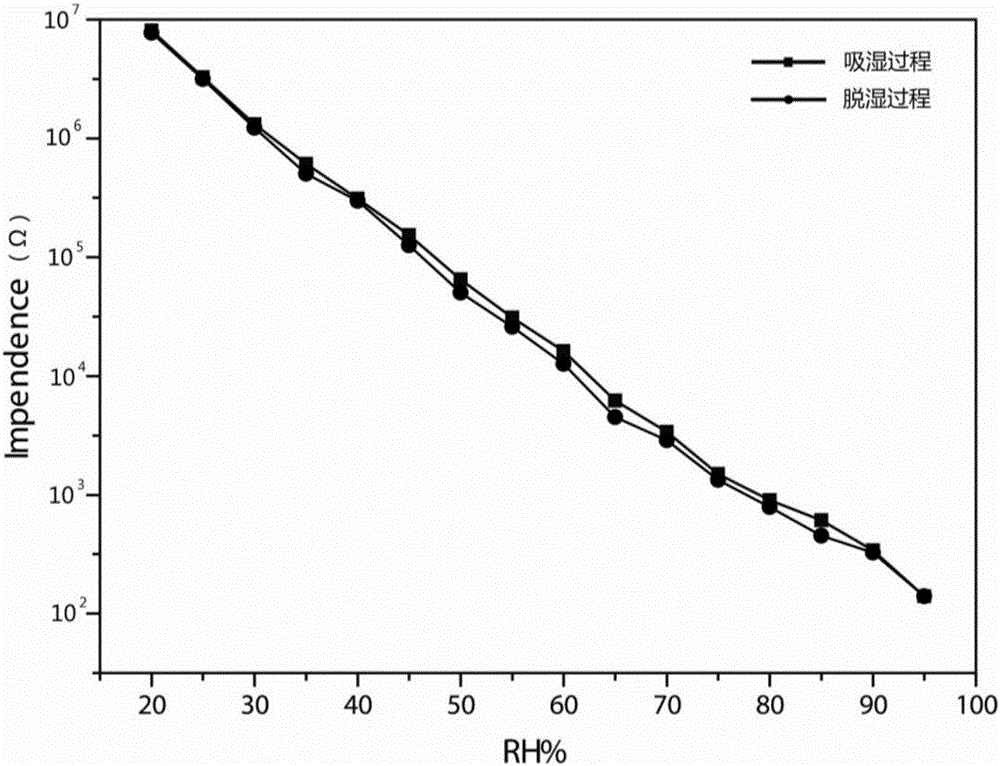

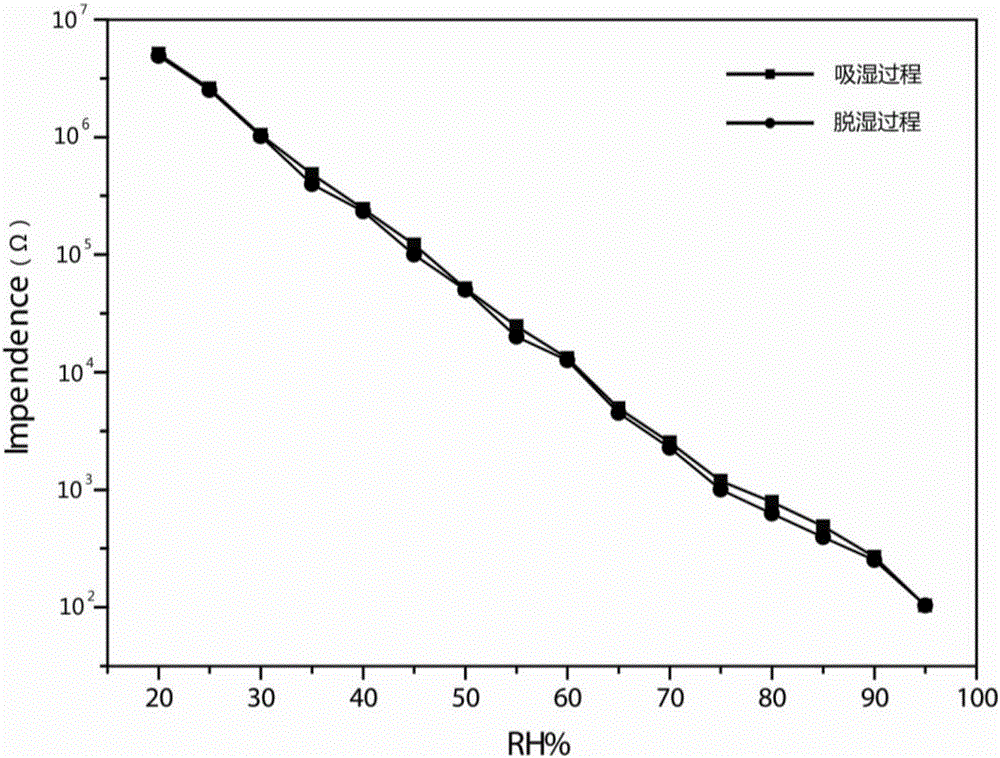

A moisture-sensitive material, resistance-type technology, applied in the analysis of materials, material analysis through electromagnetic means, material resistance, etc., can solve problems such as hindering popularization and application, poor high-humidity resistance and long-term stability, and easy slip loss. Achieve good humidity response, high humidity resistance and long-term stability, and improve water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

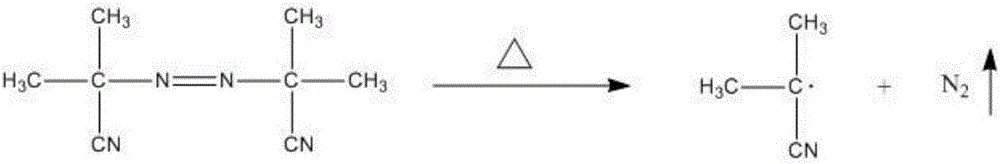

[0037] Take 20 parts of acryloyloxyethyltrimethylammonium chloride, 10 parts of acrylamide, 10 parts of methyl methacrylate, 2 parts of lithium acrylate, and 0.5 parts of initiator AIBN, and place it in a Add methanol to the four-necked flask of the condenser tube and the nitrogen protection device to completely dissolve the reactants, and then react at a constant temperature of 65-85° C. for 4 hours. After the reaction is finished, the obtained product is washed with ether, and then vacuum-dried at room temperature to obtain a resistive polymer moisture-sensitive material.

Embodiment 2

[0039] Take 20 parts of methacryloyloxyethyltrimethylammonium chloride, 40 parts of diethylaminoethyl methacrylate, 10 parts of styrene, 2 parts of sodium styrene sulfonate, 1 part of initiator AIBN, and place in a Methanol was added to a four-necked flask with a thermometer, a stirrer, a reflux condenser and a nitrogen protection device to completely dissolve the reactant, and then reacted at a constant temperature of 65-85° C. for 6 hours. After the reaction, the obtained product was washed with ether and dried in vacuum at room temperature to obtain a resistive polymer moisture-sensitive material.

Embodiment 3

[0041] Take 20 parts of methacryloylpropyltrimethylammonium chloride, 20 parts of dimethyl allylamine, 10 parts of methyl acrylate, 5 parts of sodium styrene sulfonate, and 0.8 parts of initiator AIBN, and put them in the Add methanol to a four-necked flask equipped with a thermometer, a stirrer, a reflux condenser and a nitrogen protection device to completely dissolve the reactants, and then react at a constant temperature of 65-85° C. for 6 hours. After the reaction, the obtained product was washed with ether and dried in vacuum at room temperature to obtain a resistive polymer moisture-sensitive material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com