Field-effect transistor material based on multi-fused ring, and its preparation method and application

A technology of field effect transistors and transistors, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of difficult energy level adjustment, short conjugate length, poor solubility, etc., to improve electron mobility, Good film-forming property and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

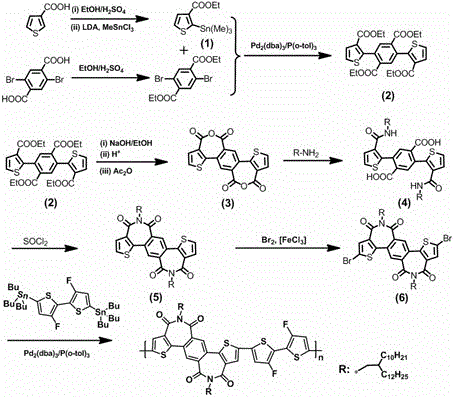

[0035] When X is an S atom, A is R is The prepared chemical structure is The preparation steps of the transistor material PIM-DTF with an n value of 1-100 are as follows:

[0036] (1) Synthesis of Compound 1: In a 250mL round-bottomed flask, 4.76g of diisopropylamine and 100mL of tetrahydrofuran were added under the protection of argon, the mixed solution was cooled to -78°C, and 19.2mL of n-butyllithium was added dropwise thereto Solution, after the dropwise addition, stirred at -78°C for 40min, then dissolved 6.01g of ethyl thiophene-3-carboxylate in 500mL of tetrahydrofuran and added dropwise to the mixed solution in the round bottom flask, after the dropwise addition, continued to stir After 1 hour, 46.1 mL of trimethyltin chloride was added dropwise. After 1 hour of reaction, the reaction liquid was heated to room temperature and stirred for 5 hours. After the reaction was completed, it was extracted with ethyl acetate, washed with water, dried with anhydrous sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com