Ecologic foamed decoration plate containing alga and calcium, and production method and application thereof

A decorative board and ecological technology, applied in the field of algae calcium ecological foamed decorative board and its preparation, to achieve the effects of improved purification rate, standardized control of appearance quality and performance, and convenient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

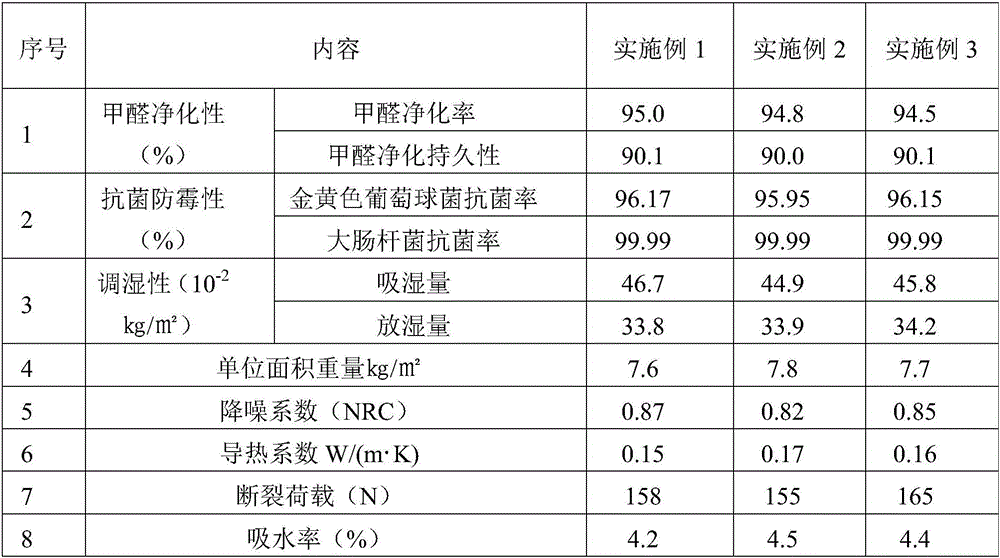

Embodiment 1

[0034] An algal calcium ecological foaming decorative board, which is made of the following raw materials in parts by weight: 84 parts of calcium-containing inorganic substrates (calcium sulfate hemihydrate), 10 parts of algae substrates (diatomaceous earth), photocatalytic mineral powder 6 parts of body (mixed by negative ion powder and shell powder in a weight ratio of 1:1), 0.1 part of foaming agent (made from deionized water, sodium lauryl sulfate, and sodium bicarbonate in a weight ratio of 97:1.5:1.5) obtained), 62 parts of compound glue (obtained by compounding deionized water, polyvinyl alcohol emulsion, potassium methyl silicate waterproofing agent, and surface defoamer of inorganic decorative board according to 100:0.8:0.1:0.6), length 1.2 parts of glass fiber chopped strands of 18-22 mm.

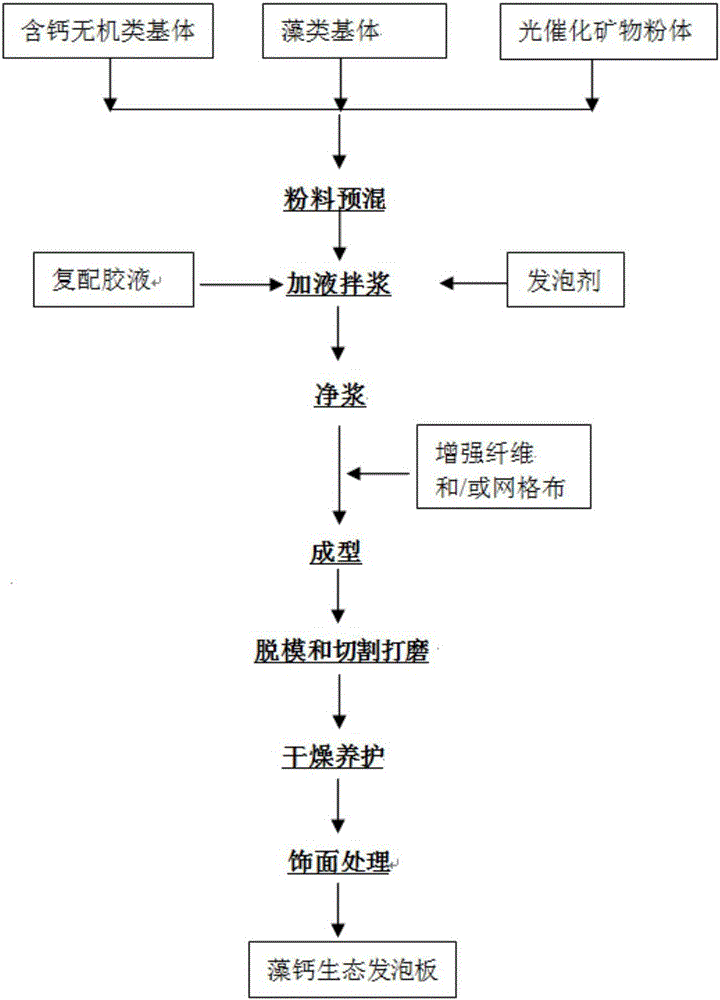

[0035] The steps of preparing the algae calcium ecological foam decorative board through the above-mentioned raw materials are as follows:

[0036] S1. Powder premixing: mix the ...

Embodiment 2

[0043] An algal calcium ecological foam decorative board, which is made of the following raw materials in parts by weight: 82 parts of calcium-containing inorganic substrates (calcium phosphate), 5 parts of algae substrates (seaweed), and 5 parts of photocatalytic mineral powder (nano-titanium dioxide), 0.05 parts of foaming agent (obtained by compounding deionized water, sodium lauryl sulfate, and sodium bicarbonate at a weight ratio of 97:0.1:0.1), 60 parts of compound glue (by deionized Water, polyvinyl alcohol emulsion, potassium methyl silicate waterproofing agent, inorganic decorative board surface defoamer compounded at 100:1.0:1.1:1.2), 0.8 part of chopped plant fiber with a length of 18-22 mm.

[0044] The steps of preparing the algae calcium ecological foam decorative board through the above-mentioned raw materials are as follows:

[0045] S1. Powder premixing: mix the calcium-containing inorganic matrix, the algae matrix and the photocatalytic mineral powder uniform...

Embodiment 3

[0052] An algal calcium ecological foam decorative board, which is made of the following raw materials in parts by weight: 90 parts of calcium-containing inorganic substrates (calcium aluminate), 8 parts of algal substrates (diatomite and seaweed 1:1 by weight) ratio mixing), 8 parts of photocatalytic mineral powder (mixed by attapulgite, shell powder, sepiolite, negative ion powder, etc. by weight ratio), 0.18 parts of foaming agent (made of deionized water, sodium lauryl sulfate, Sodium bicarbonate is compounded according to the weight ratio of 99:1.2:1.2), 75 parts of compound glue (composed of deionized water, polyvinyl alcohol emulsion, potassium methyl silicate waterproofing agent, inorganic decorative board surface defoamer according to 100:1.2:1.8:2.0), 4.2 parts of chopped mineral fiber with a length of 18-22mm, and 2.8 parts of glass fiber mesh cloth with a specification of 4×4mm.

[0053] The steps of preparing the algae calcium ecological foam decorative board thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com