Three-dimensional printing device with injector head capable of being vibrated

A printing device and spray head technology, which is applied in coating devices, manufacturing auxiliary devices, processing and manufacturing, etc., can solve the problems of loose structure of 3D printed parts, weak product compactness, poor mechanical properties, etc., and achieve quality and Improvement of appearance quality, improvement of quality and appearance quality, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

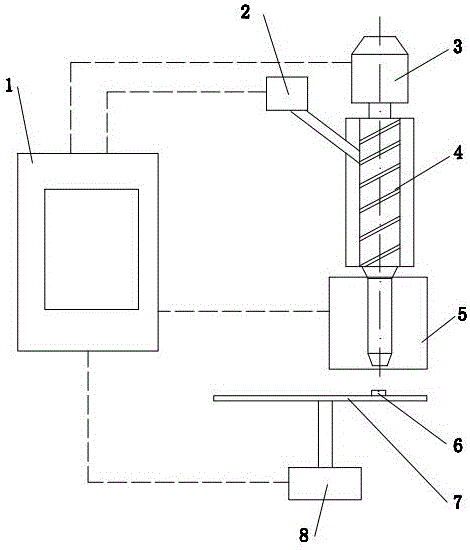

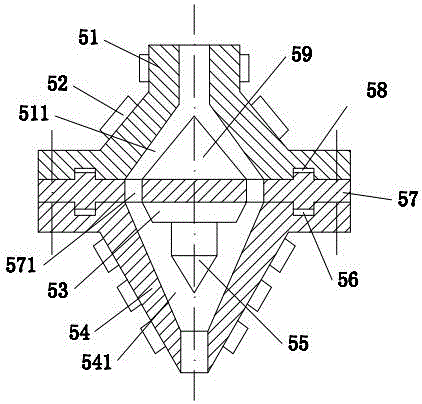

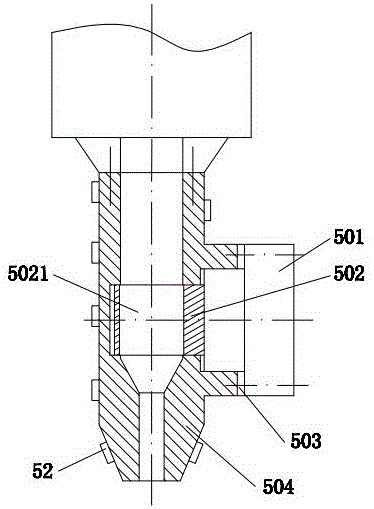

[0038] like figure 1 As shown, it is a 3D printing device with a vibrating ejector head, including a control system 1, a powder supply system 2, a motor drive system 3, a screw extrusion system 4, a first ejector head 5, a workbench 7 and a working table. Table moving system 8; wherein the first injection head 5 is connected to the lower end of the screw extrusion system 4 and communicated with its discharge port, and the motor drive system 3 drives the screw to rotate to complete the screw, extrusion and melting of the material And transport materials to the first injection head 5, the motor drive system 3, the screw extrusion system 4 and the first injection head 5 are integrated and can move horizontally in the X-axis and Y-axis directions above the workbench 7 , the workbench moving system 8 drives the workbench 7 to move vertically up and down, and the control system 1 controls the powder supply system 2, the motor drive system 3, the screw extruding system 4, the first s...

Embodiment 2

[0045] like Figure 9 As shown, it is a 3D printing device in which the ejection head can vibrate, including a control system 1, a worktable 7, a worktable moving system 8, a second ejection head 9, a wire feeding mechanism 10, a guide sleeve 12 and a wire winding material The wire feeding reel 13; wherein the wire material 11 on the wire feeding reel 13 passes through the guide sleeve 12, and the wire feeding motor on the wire feeding reel 13 drives the wire material 11 passing through the guide sleeve 12 to enter the wire feeding mechanism 10 , the second injection head 9 is connected to the lower end of the wire feeding mechanism 10 and communicates with its discharge port. Horizontal movement in the axial direction, the workbench moving system 8 drives the workbench 7 to move vertically up and down, and the control system 1 controls the workbench moving system 8, the second spray head 9, the wire feeding mechanism 10 and the wire feeding plate 13 respectively The work of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com