Low-load palladium-platinum core-shell structure catalyst and preparation method and application thereof

A core-shell structure, low-load technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. High volume, cumbersome operation, etc., to achieve the effect of reusable raw materials, low environmental cost, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Will Pd 2 (dba) 3 (0.22g, 2.4×10 -4 mol) was added into PC (100mL), under 3MPa hydrogen environment and room temperature, stirred and reacted for 2h to obtain a solution containing Pd nanoparticles, Al 2 o 3 Carrier (100g) was added to the obtained solution containing Pd nanoparticles, stirred for 12h, filtered with suction, and the filter cake was vacuum-dried at 100°C for 5h to obtain Pd / Al 2 o 3 Catalyst 100g.

[0031] The loading amount of metal Pd in the obtained catalyst was 0.03wt%.

Embodiment 2

[0033] H 2 PtCl 6 ·6H 2 O (0.13g, 2.5×10 -4 mol) was added to PC (100mL), under 3MPa hydrogen environment and room temperature, stirred and reacted for 2h to obtain a solution containing Pt nanoparticles, Al 2 o 3 Carrier (100g) was added to the obtained solution containing Pd nanoparticles, stirred for 12h, filtered with suction, and the filter cake was vacuum-dried at 100°C for 5h to obtain Pt / Al 2 o 3 Catalyst 100g.

[0034] The loading amount of metal Pt in the obtained catalyst was 0.03wt%.

Embodiment 3

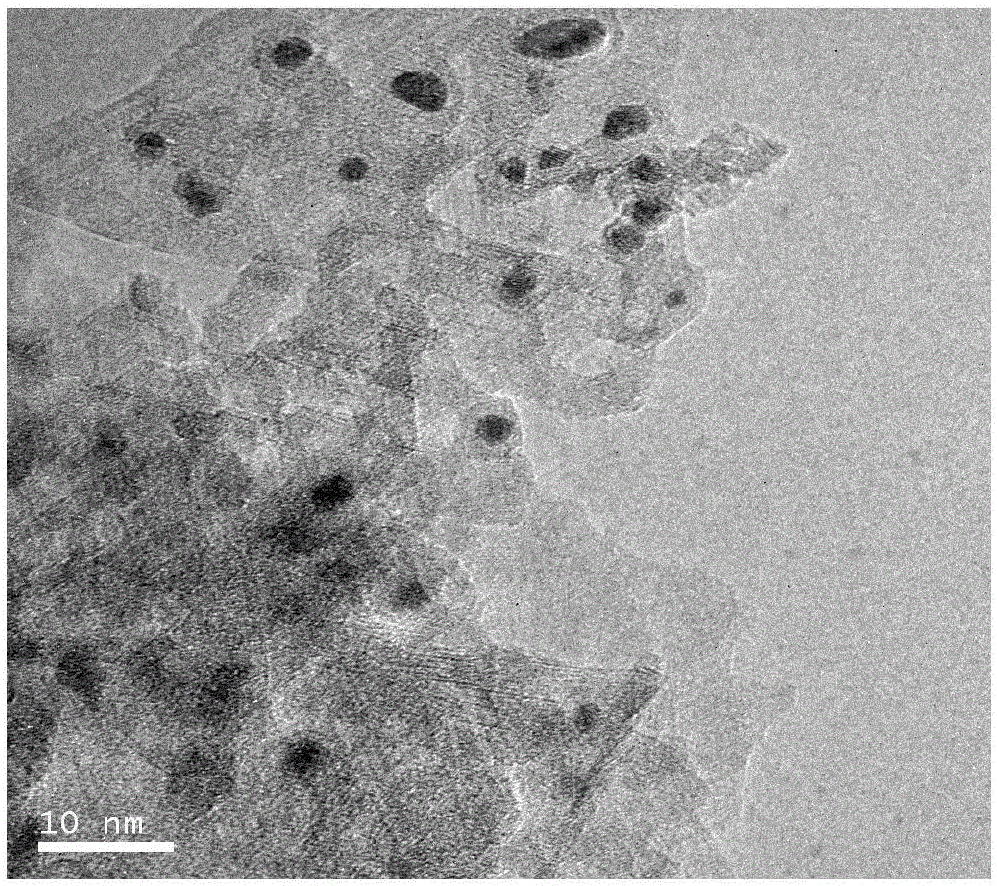

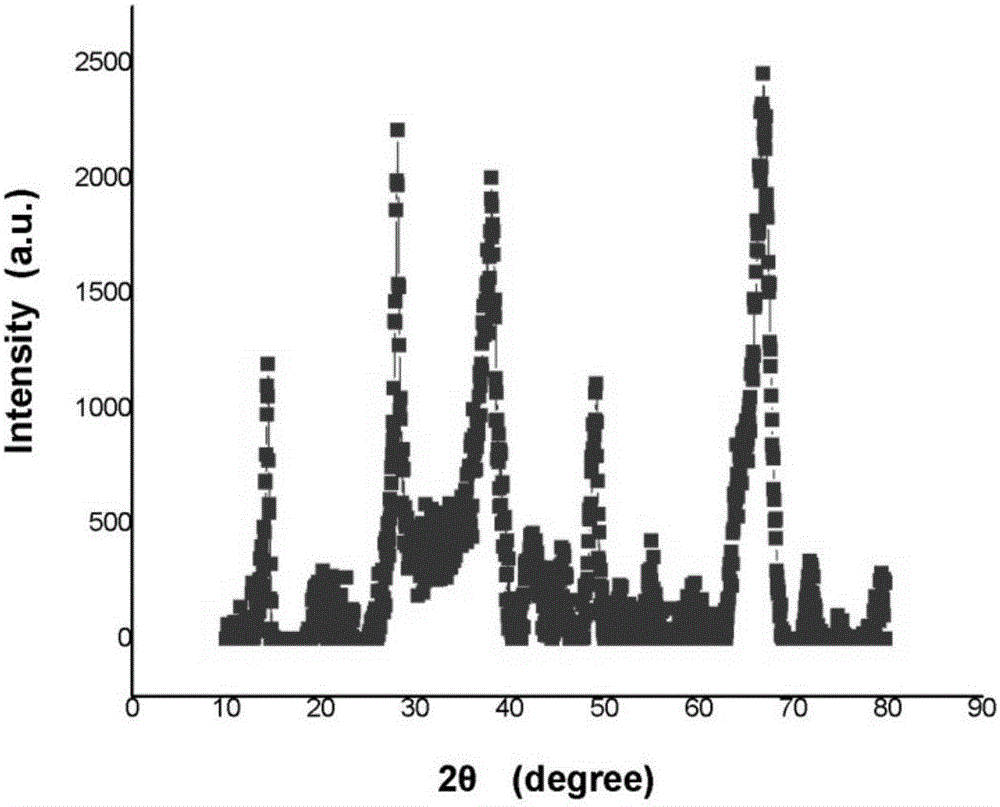

[0036] Will Pd 2 (dba) 3 (0.023g, 2.5×10 -5 mol) mixed with propylene carbonate (100mL), under 3MPa hydrogen atmosphere and room temperature, stirred for 2h to obtain a solution containing Pd nanoparticles; 2 PtCl 6 ·6H 2 O (0.027g, 5.2×10 -5mol) was added to the obtained solution containing Pd nanoparticles, and stirred and reacted for 2 hours under 3MPa hydrogen atmosphere and room temperature to obtain a solution containing the active component of the core-shell structure; the solution and the carrier Al 2 o 3 (100g) mixed, stirred for 12h, suction filtered, and the filter cake was vacuum-dried (100°C, dried for 5h) to obtain Pd@Pt / Al 2 o 3 Catalyst 100g.

[0037] The total loading of metals Pd and Pt in the obtained catalyst was 0.03 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com