Dome roof tank provided with fire fighting facility

A technology of fire-fighting facilities and vaulted tanks, applied in containers, packaging, fire rescue, etc., can solve problems such as damage, achieve the effect of suppressing flames and preventing secondary explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

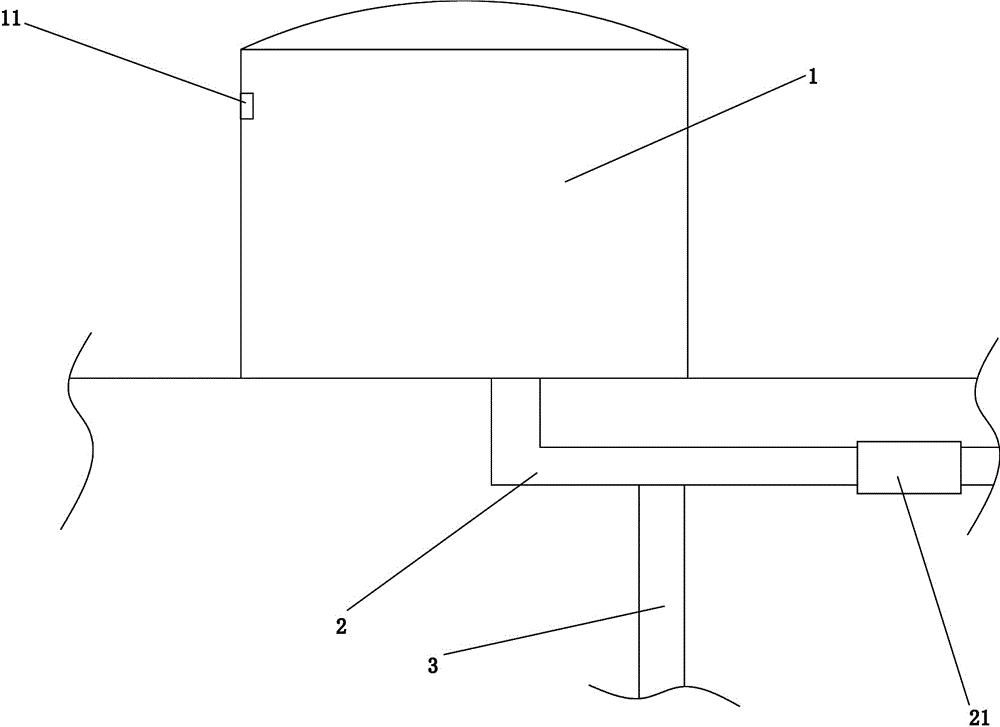

[0017] Example 1, such as figure 1 As shown, a vaulted tank with fire-fighting facilities includes a tank body 1, the bottom of the tank body 1 is provided with a delivery pipe 2, the delivery pipe 2 is buried under the ground, and the delivery pipe 2 is also A pressure valve is provided, and the pressure valve is an electronic pressure valve 21 . The tank body 1 is provided with a pressure detector 11, and the bottom of the tank body 1 is also provided with a fire extinguishing agent delivery pipe 3 buried under the ground, and the fire extinguishing agent delivery pipe 3 is connected to the delivery pipe 2 The connecting section between the fire extinguishing agent delivery pipe 3 and the delivery pipe 2 is upstream of the electronic pressure valve 21 . The electronic pressure valve 21 starts to work after receiving the signal from the pressure detector 11 , and the conveying pipe 2 transports the storage in the tank 1 to the outside according to the instruction of the pres...

Embodiment 2

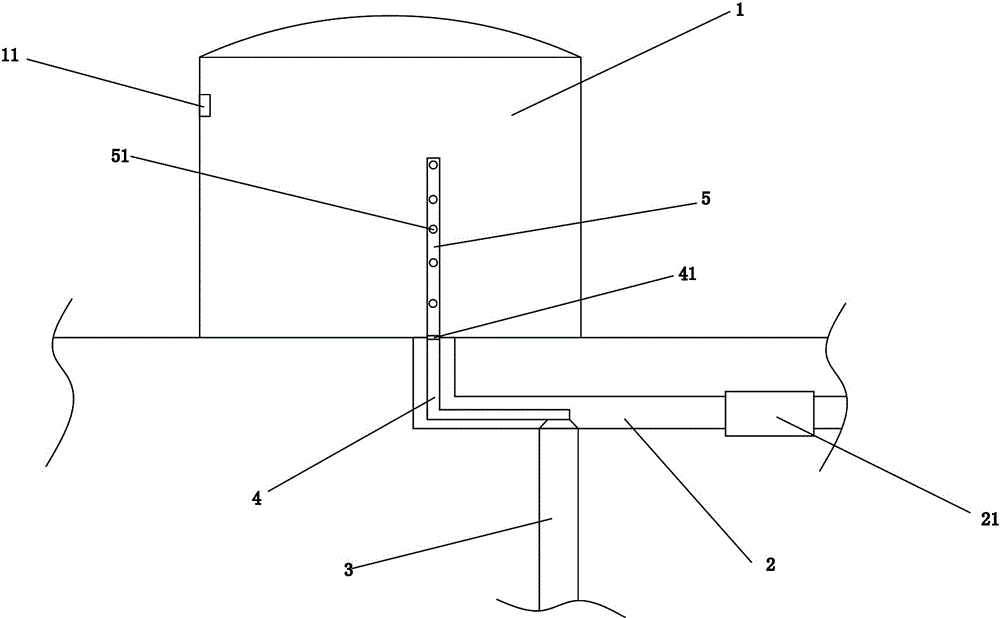

[0019] Example 2, such as figure 2 As shown, a vaulted tank with fire-fighting facilities includes a tank body 1, the bottom of the tank body 1 is provided with a delivery pipe 2, the delivery pipe 2 is buried under the ground, and the delivery pipe 2 is also A pressure valve is provided, and the pressure valve is an electronic pressure valve 21 . The tank body 1 is provided with a pressure detector 11, and the bottom of the tank body 1 is also provided with a fire extinguishing agent delivery pipe 3 buried under the ground, and the fire extinguishing agent delivery pipe 3 is connected to the delivery pipe 2 The connecting section between the fire extinguishing agent delivery pipe 3 and the delivery pipe 2 is upstream of the electronic pressure valve 21 . The delivery pipe 2 is provided with a connecting thin tube 4, one section of the connecting thin tube 4 is connected to the fire extinguishing agent delivery pipe 3, and the other end protrudes into the tank body 1, and th...

Embodiment 3

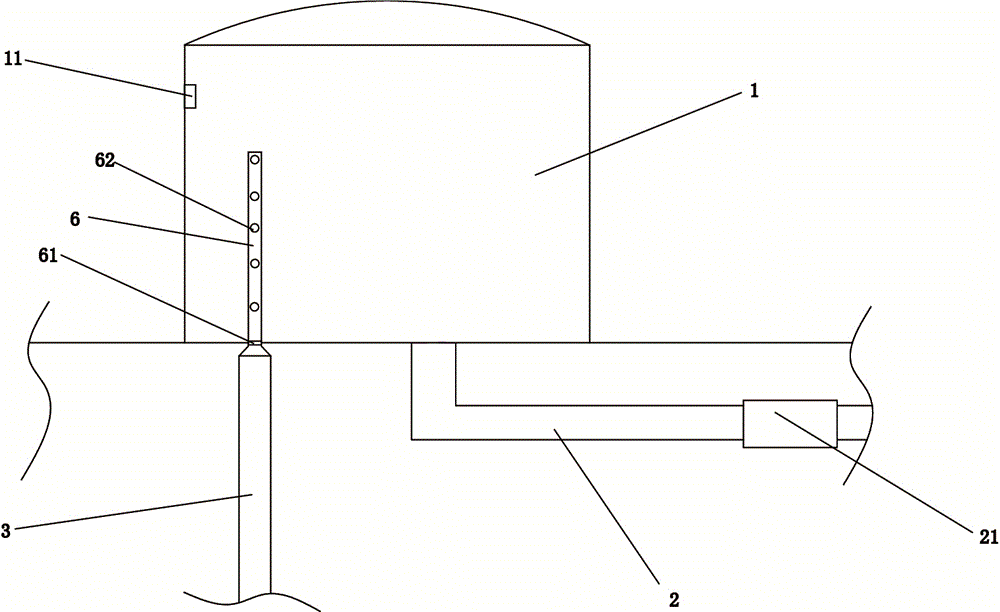

[0021] Example 3, such as image 3 As shown, a vaulted tank with fire-fighting facilities includes a tank body 1, the bottom of the tank body 1 is provided with a delivery pipe 2, the delivery pipe 2 is buried under the ground, and the delivery pipe 2 is also A pressure valve is provided, and the pressure valve is an electronic pressure valve 21 . The tank body 1 is provided with a pressure detector 11, and the bottom of the tank body 1 is also provided with a fire extinguishing agent delivery pipe 3 buried under the ground, and the fire extinguishing agent delivery pipe 3 communicates with the bottom of the tank body 1 A check valve 61 is provided between the fire extinguishing agent delivery pipe 3 and the bottom of the tank body 1 . The fire extinguishing agent delivery pipe 3 is provided with a second injection pipe 6 extending into the tank body 1, and several one-way valves 62 are uniformly arranged on the wall of the second injection pipe 6 .

[0022]The vaulted tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com