Heatable heat-insulating mattress

A technology for heating and thermal insulation, mattresses, applied in the direction of beds, other seating furniture, applications, etc., can solve the problems of easy breeding of bacteria and mites, reduced comfort, easy dampness of mattresses, etc., to achieve sleep quality and physical health benefits, reduce Heat loss, effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

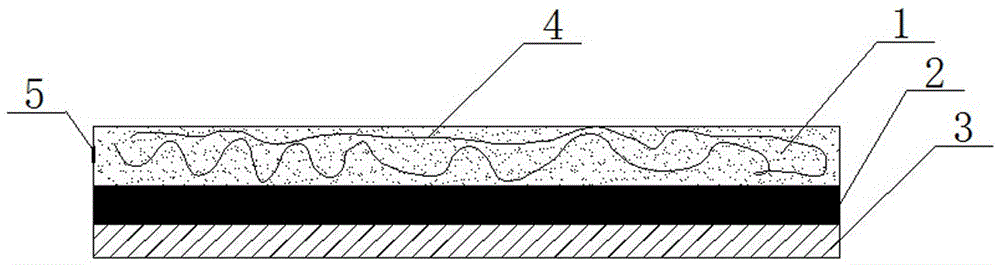

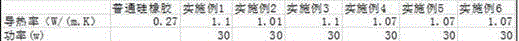

[0022] Specific embodiment 1: as figure 1 As shown, this embodiment discloses a heat-insulating mattress, including a heating layer 1, a heat-insulating layer 2, and a bottom layer 3. The heat-insulating layer 2 is located between the heating layer 1 and the bottom layer 3, and the two layers are different The heating layer 1 includes a heating layer body, a heating wire 4, and a switch 5. The heating layer body is made of heat-conducting silicone rubber, and the heat insulating layer 2 is polyurethane foam. The bottom layer 3 is a non-woven fabric. , the thickness of the heating layer 1 is 20 mm, the thickness of the heat insulation layer 2 is 20 mm, and the heating wire is a copper heating wire.

[0023] The thermally conductive silicone rubber described in this embodiment includes 100 parts of silicone rubber matrix, 1 part of thermally conductive material alumina, 1 part of coupling agent KH570, 1 part of flame retardant, and 1 part of toughening agent styrene-butadiene t...

specific Embodiment 2

[0026] Specific embodiment 2: as figure 1 As shown, this embodiment discloses a heat-insulating mattress, including a heating layer 1, a heat-insulating layer 2, and a bottom layer 3. The heat-insulating layer 2 is located between the heating layer 1 and the bottom layer 3, and the two layers are different The heating layer 1 includes a heating layer body, a heating wire 4, and a switch 5. The heating layer body is made of heat-conducting silicone rubber, and the heat insulating layer 2 is polyurethane foam. The bottom layer 3 is a non-woven fabric. , the thickness of the heating layer 1 is 50 mm, the thickness of the heat insulation layer 2 is 30 mm, and the heating wire is an aluminum fiber heating wire.

[0027] The thermal conductive silicone rubber described in this embodiment includes 100 parts of silicone rubber matrix, 20 parts of thermal conductive material alumina, 5 parts of coupling agent TMC-102, 5 parts of flame retardant, toughening agent styrene-butadiene ther...

specific Embodiment 3

[0029] Specific embodiment 3: as figure 1 As shown, this embodiment discloses a heat-insulating mattress, including a heating layer 1, a heat-insulating layer 2, and a bottom layer 3. The heat-insulating layer 2 is located between the heating layer 1 and the bottom layer 3, and the two layers are different The heating layer 1 includes a heating layer body, a heating wire 4, and a switch 5. The heating layer body is made of heat-conducting silicone rubber, and the heat insulating layer 2 is polyurethane foam. The bottom layer 3 is a non-woven fabric. , the thickness of the heating layer 1 is 100 mm, the thickness of the heat insulation layer 2 is 50 mm, and the heating wire is a carbon fiber heating wire.

[0030] The thermally conductive silicone rubber described in this embodiment includes 100 parts of a silicone rubber matrix, 50 parts of a thermally conductive material alumina, 10 parts of a coupling agent TMC-102, 10 parts of a flame retardant, and 10 parts of a toughenin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com