A real-time monitoring system for flue-cured tobacco leaf processing

A real-time monitoring, flue-cured tobacco leaf technology, applied in the control/adjustment system, simultaneously controlling multiple variables, tobacco and other directions, can solve problems such as heavy workload and achieve good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

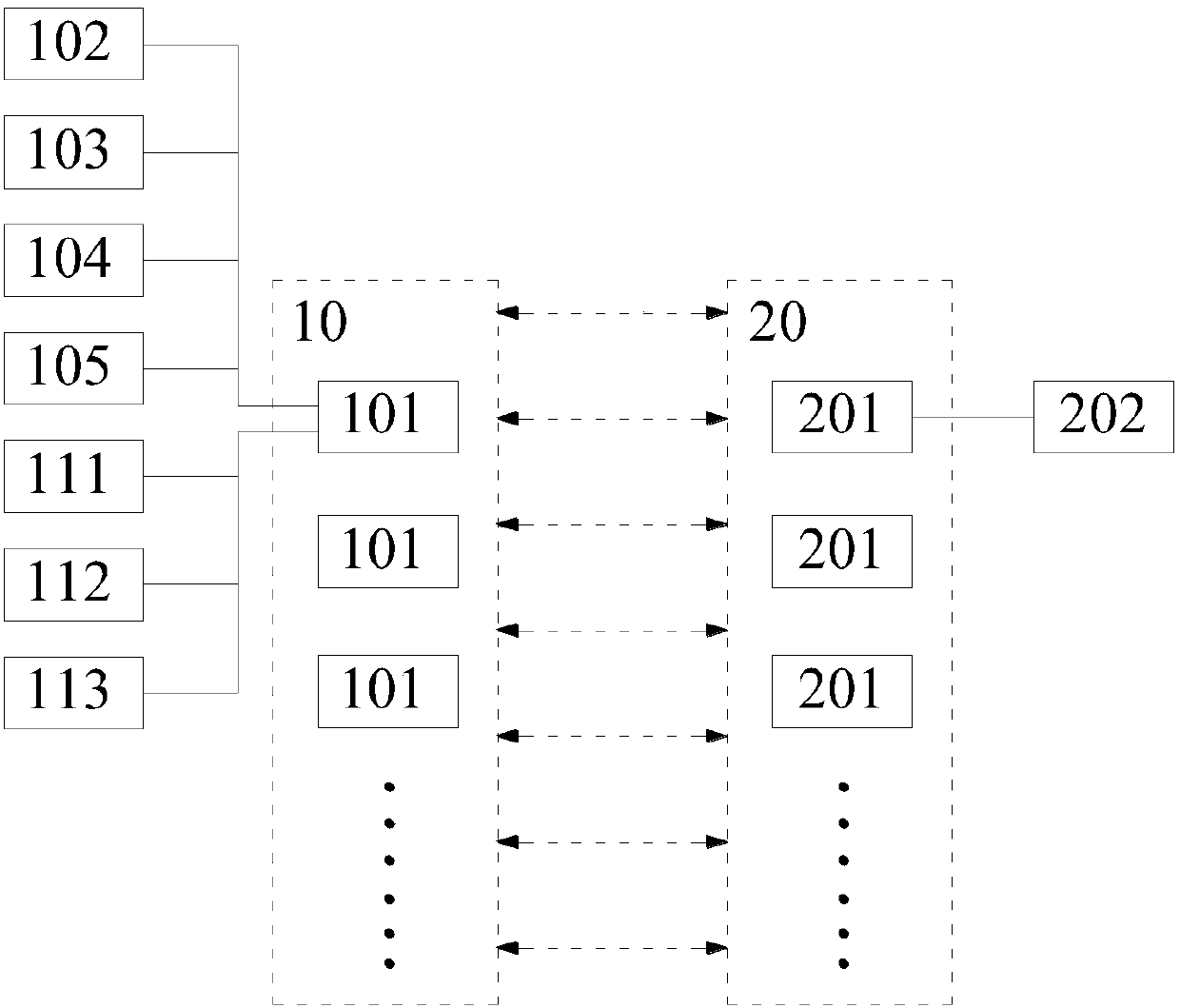

[0015] Such as figure 1 A real-time monitoring system for flue-cured tobacco leaf processing shown includes a user group 10 composed of a plurality of user hosts 101 and an expert group 20 composed of a plurality of expert systems 201; each expert system 201 is established by server authentication; each user Host 101 is respectively connected to temperature sensor 102, humidity sensor 103, air volume detector 104, odor sensor 105 and collects the data of temperature sensor 102, humidity sensor 103, air volume detector 104, odor sensor 105; Described user host 101 randomly selects experts The system 201 sends the data of the temperature sensor 102, the humidity sensor 103, the air flow detector 104, and the odor sensor 105 and obtains the corresponding result value, then displays it to the user, and adjusts the evaluation value of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com