Online dynamic balance correction method of large-size draught fan impeller

A technology of fan impeller and correction method, applied in static/dynamic balance test, machine/structural component test, measurement device, etc., can solve problems such as wasting time and affecting normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

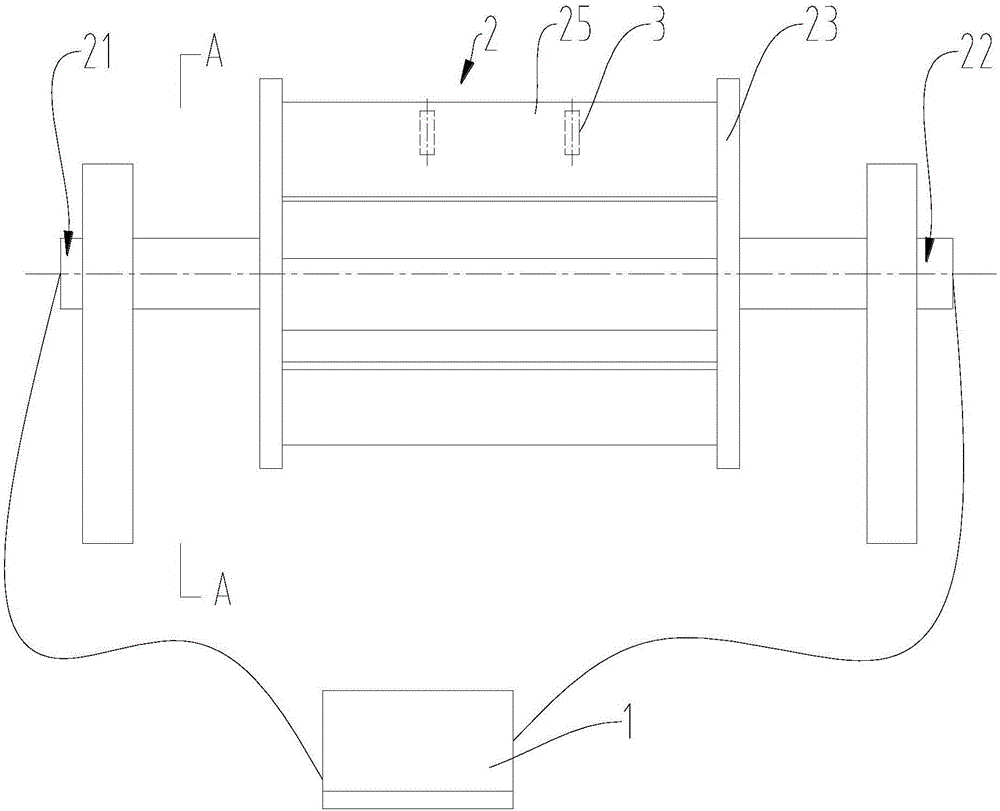

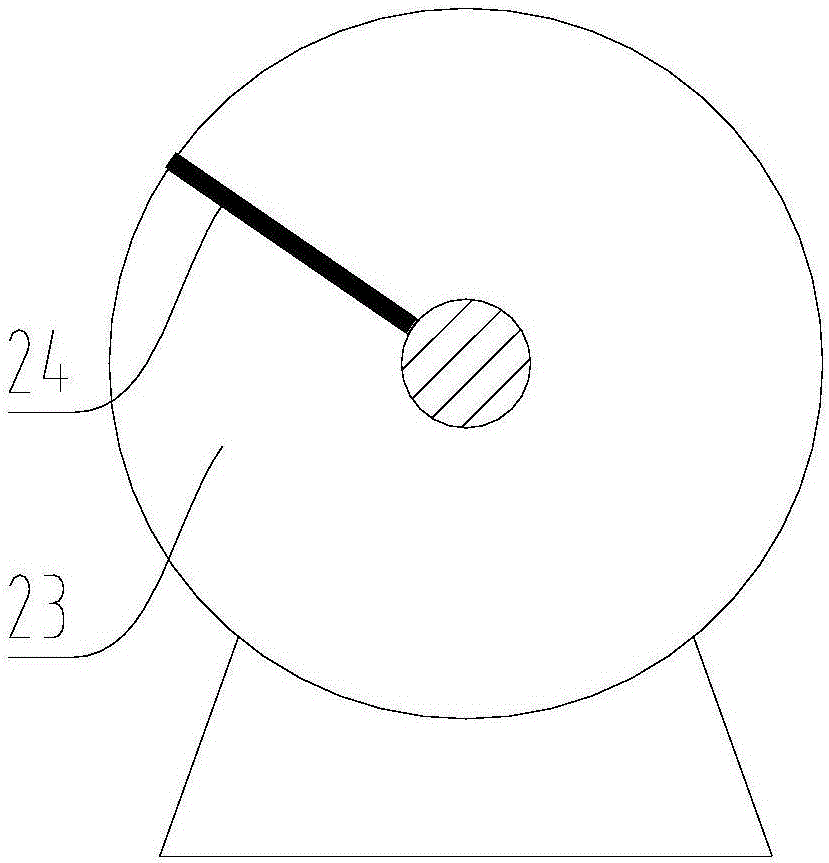

[0031] An ironworks has adopted the above method three times to carry out on-site dynamic balance correction on the impeller of the circulating fan of the CDQ system after repair. Fan model: 25151Z / 1024, fan speed n=1500r / min, fan mass W=7800Kg.

[0032] the first time:

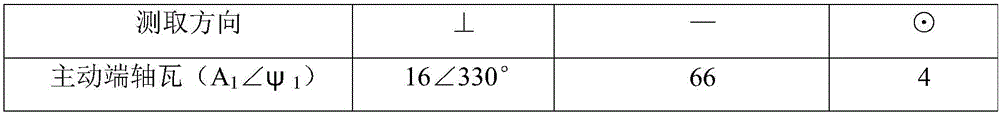

[0033] First of all, the original vibration amplitude and phase of the bearing bush at the driving end 21 and the passive end 22 of the fan impeller are measured with the vibration detection balance instrument 1 on site, as shown in Table 1:

[0034] Table 1 The original vibration amplitude and phase of the fan bearing

[0035]

[0036]

[0037] In Table 1: ⊥ means the vertical direction, — means the horizontal direction, and ⊙ means along the impeller axis.

[0038] It can be seen from Table 1 that the vertical vibration phases of the bearing pad at the active end and the bearing pad at the passive end are basically the same, but the vibration amplitudes are greatly different. It is a typical dynami...

Embodiment 2

[0071] Example 2: A certain ironworks adopted the above method to perform on-line dynamic balance correction on the impeller of the repaired coke screening and dust removal fan. The coke screening fan model: CGR218-73DIF, the conveying medium is coke dust and flue gas; fan speed n=1600r / min, rotor mass W=8100Kg; radius R=1250mm.

[0072] First of all, the original vibration amplitude and phase of the bearing bush at the driving end 21 and the passive end 22 of the fan impeller are measured with the vibration balance instrument 1 on site, as shown in Table 7:

[0073] Table 7 Original vibration amplitude and phase of fan bearing

[0074] Measure direction ⊥ — ⊙ Drive end bearing bush (A 1 ∠ψ 1 )

17∠330° 67 5 Bearing bush at passive end (A 2 ∠ψ 2 )

9∠320° 35 18

[0075] For the impeller of the C-series coke dust removal fan, the mass of the rotor is W=8100Kg; the radius R=1250mm; the speed n=1600r / min; the above parameters are brough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com