Rigid electric drive rear axle wheel rim assembly for microcirculation vehicle

An assembly and rigid technology, which is applied in the field of rigid electric drive rear axle wheel side assemblies for micro-cycle vehicles, can solve the problems of high maintenance and maintenance costs, difficult assembly and maintenance, and short wheel side maintenance cycles. The effect of short wheel maintenance cycle, high assembly accuracy and improved wheel maintenance mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

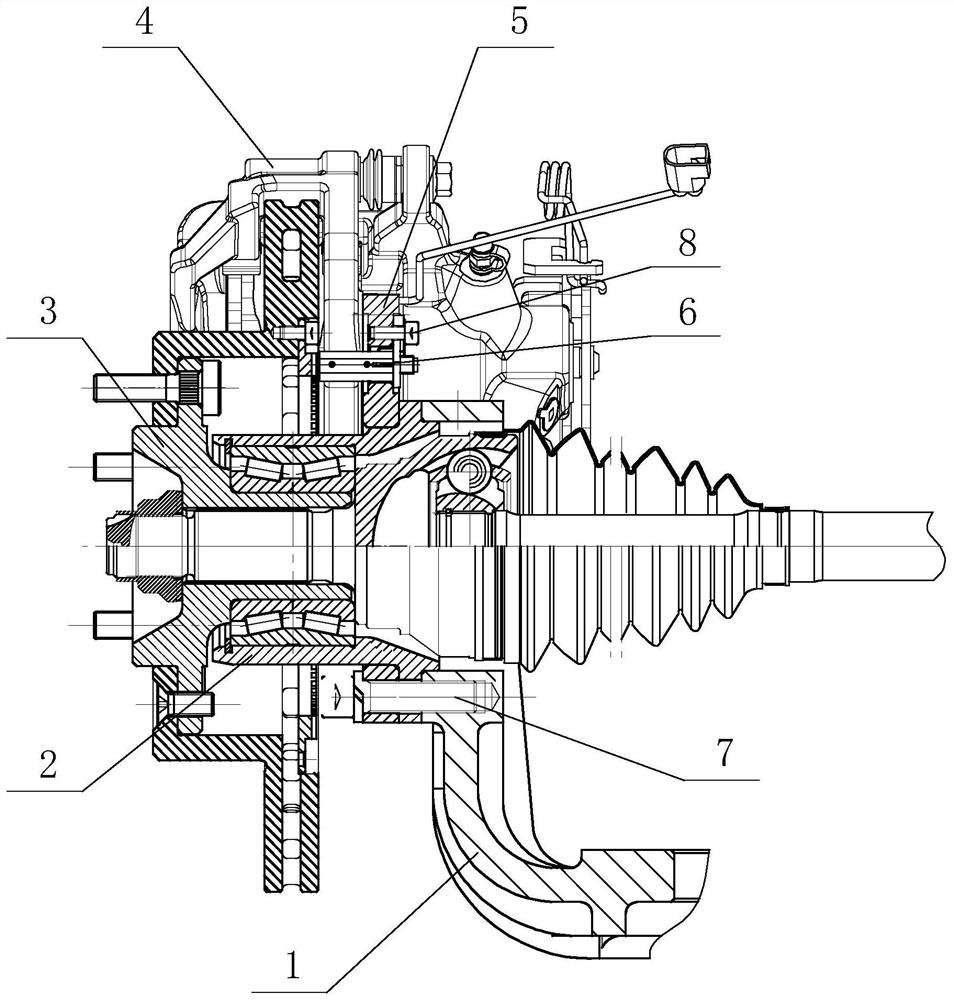

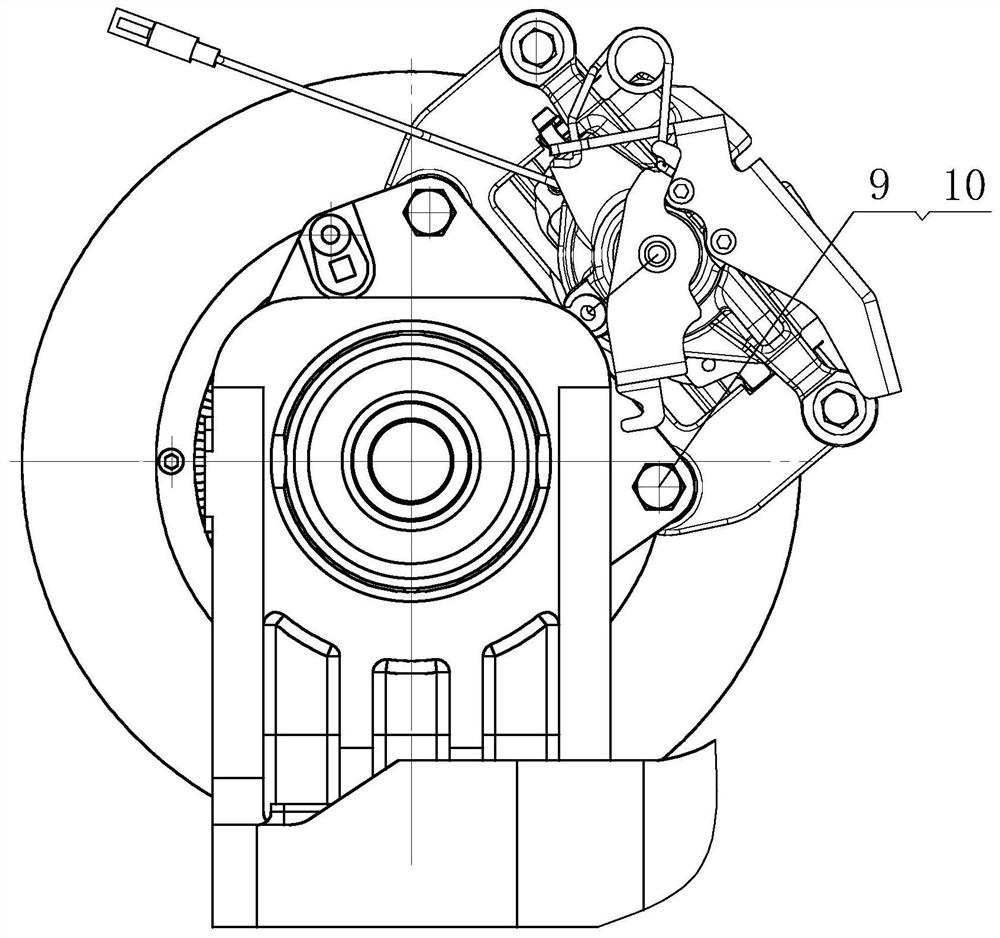

[0039] A rigid electric drive rear axle wheel assembly for a microcirculation vehicle, including a support frame 1, a bearing seat assembly 2, a wheel hub and brake disc assembly 3, a hydraulic brake caliper assembly 4, a mounting plate 5, and an ABS sensor 6, of which:

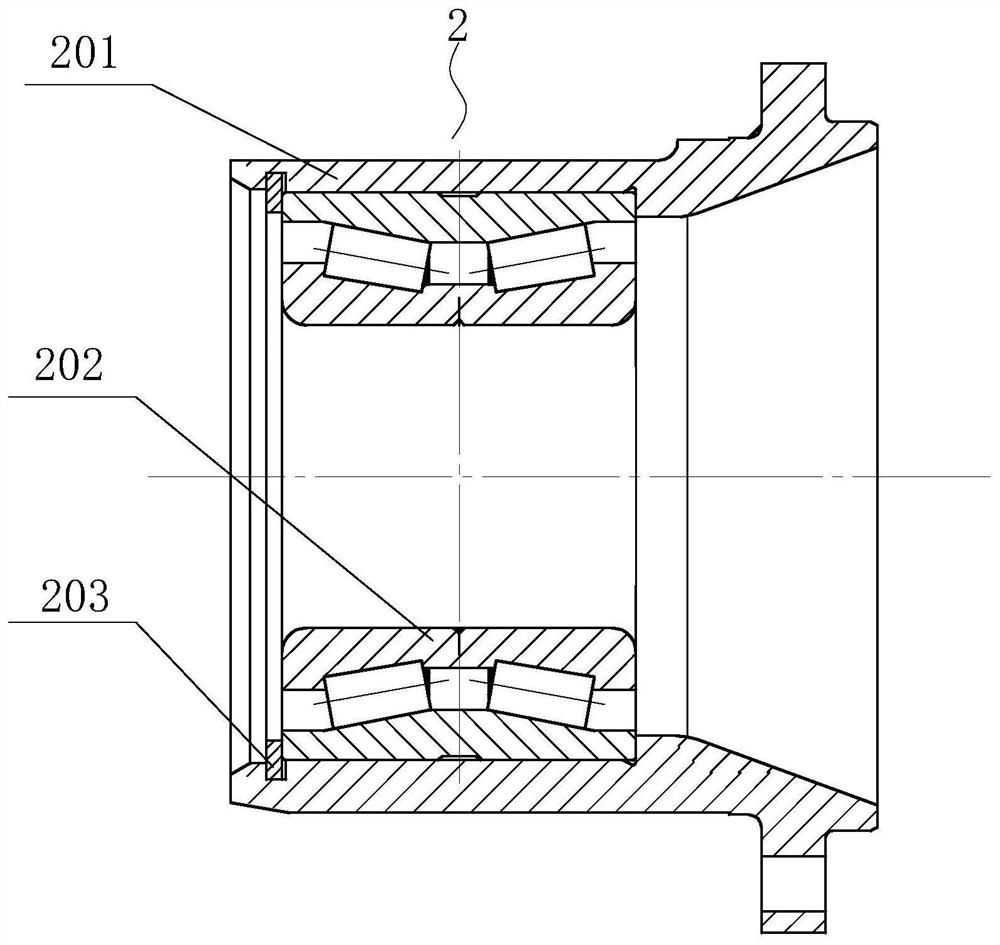

[0040] The bearing seat assembly 2 is an integral unit bearing. The bearing seat assembly 2 includes a bearing seat body 201, a unit bearing 202, and a hole retaining ring 203. The outer circle of the bearing seat body 201 is provided with a The notch 2014 of the mounting plate 5 and the light hole 2015 for passing through the hexagon socket head cap screw I; one end of the inner hole of the bearing seat body 201 is a bearing hole 2011, and the other end is a tapered hole 2012 for installing the drive shaft, and the tapered hole The diameter of the small end of 2012 is smaller than the diameter of the bearing hole 2011, and the bearing seat body 201 is also provided with a groove 2013 at the outer end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com