Integral Hoisting Method of Hydraulic Cylinder in Confined Space

An overall hoisting and confined space technology, which is applied in the direction of transportation and packaging, load hanging components, etc., to reduce the disassembly process, protect the equipment body, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

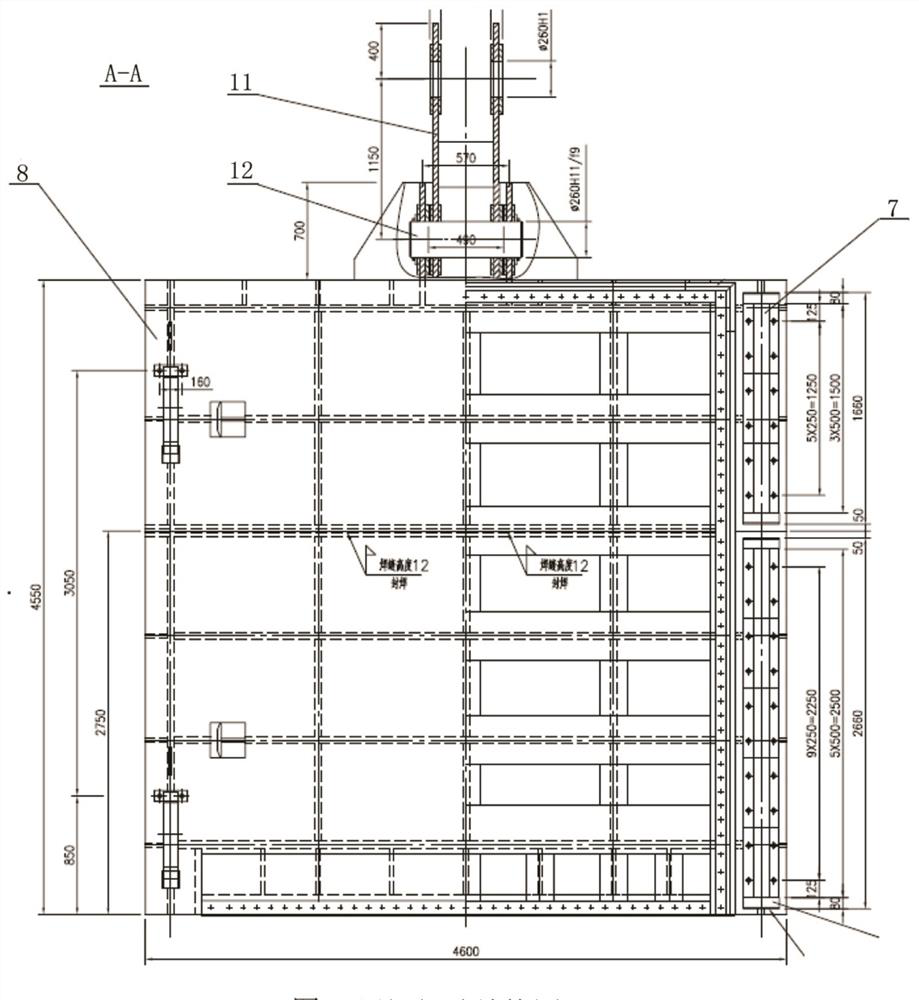

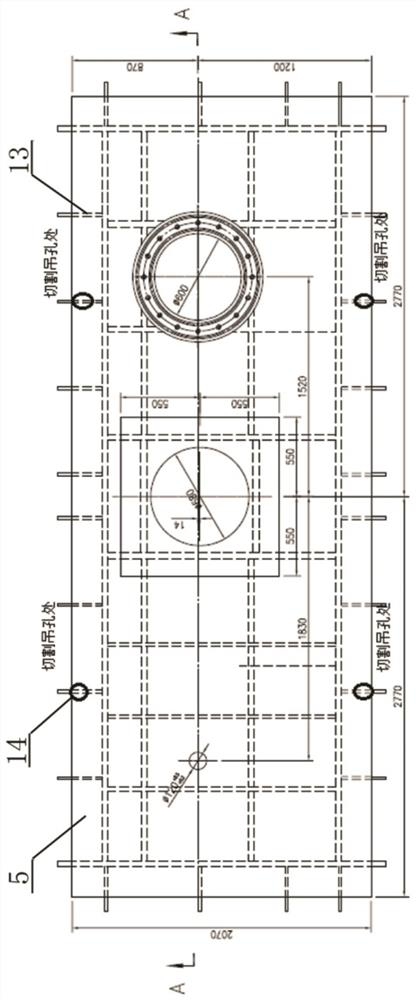

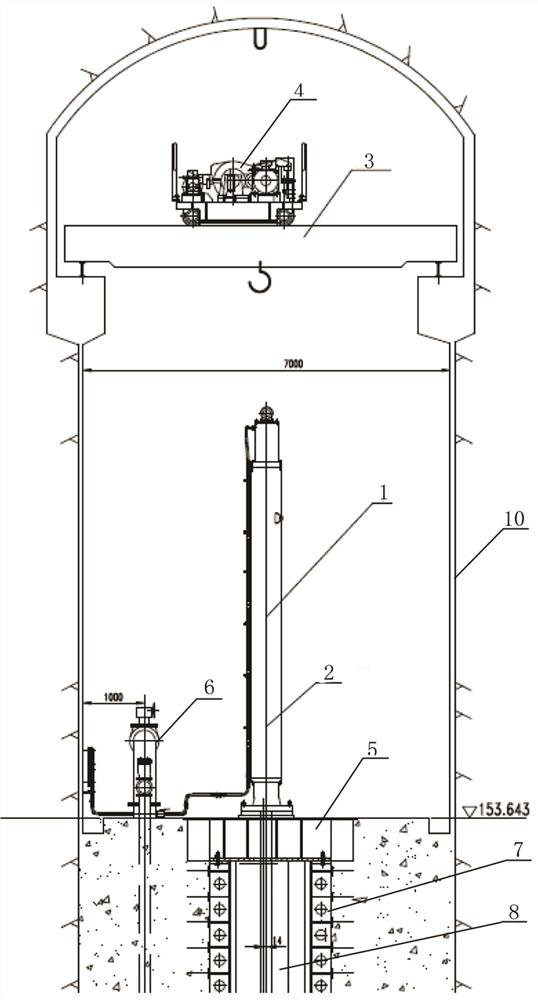

[0027] Example 1: In order to ensure the smooth implementation of the overhaul of the gate system, the existing equipment and systems are analyzed and studied, and the following overall hoisting solutions are obtained.

[0028] (1) After the tailwater tunnel of the unit is emptied, the maintenance personnel strictly follow the safety management regulations for working in a limited space, enter the lower part of the gate groove 7 through the tailwater inlet door, and place two square logs with a height of 200mm directly below the gate. It is used to support the gate body 8, and at the same time, the space at the bottom can drain away the tunnel seepage water. After the gate was implemented on the square timber, the hydraulic cylinder hanger 12 was disassembled. Start the oil station, retract the piston rod of the hydraulic cylinder, and put into hydraulic locking.

[0029] (2) Considering that the hydraulic cylinder 1 and the top cover of the gate slot are forcibly cut, the me...

Embodiment 2

[0039] Embodiment 2: Another overall hoisting method of a hydraulic cylinder in a confined space. First, after the tailwater tunnel of the unit is emptied, the maintenance personnel enter the lower part of the gate groove through the tailwater inlet door, and place the high-level h1 vertically and symmetrically directly below the gate. The bottom positioning frame is used to support the gate body 8, such as Figure 5 The bottom positioning frame shown includes a base 23 and a support member 25. Fixing bolts 24 are installed vertically at symmetrical positions on both sides of the base, and screw holes 27 are vertically arranged on the two support members and are installed on corresponding fixing bolts. , the supporting surfaces 26 on the upper sides of the two supporting members are supported on the bottom of the gate body. The height of the support can be adjusted by rotating the support so as to achieve the most reasonable support height.

[0040] Further drain away the see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com