Device for improving gas energy of light gas gun by using microwave

A light gas cannon and gas technology, which is applied to weapons without explosives, electromagnetic launchers, offensive equipment, etc., can solve the problems of increasing system security, restricting the use efficiency of light gas cannons, and requiring too high pressure resistance , to achieve the effect of reducing time spent, low additional quality, and reducing time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

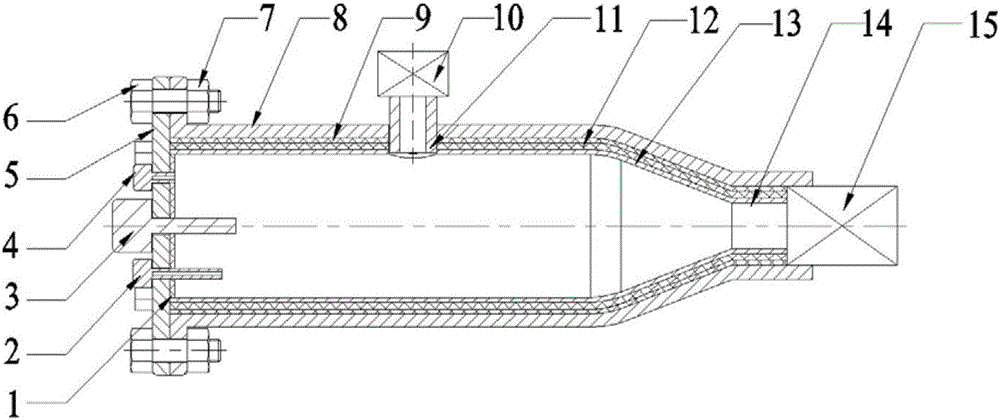

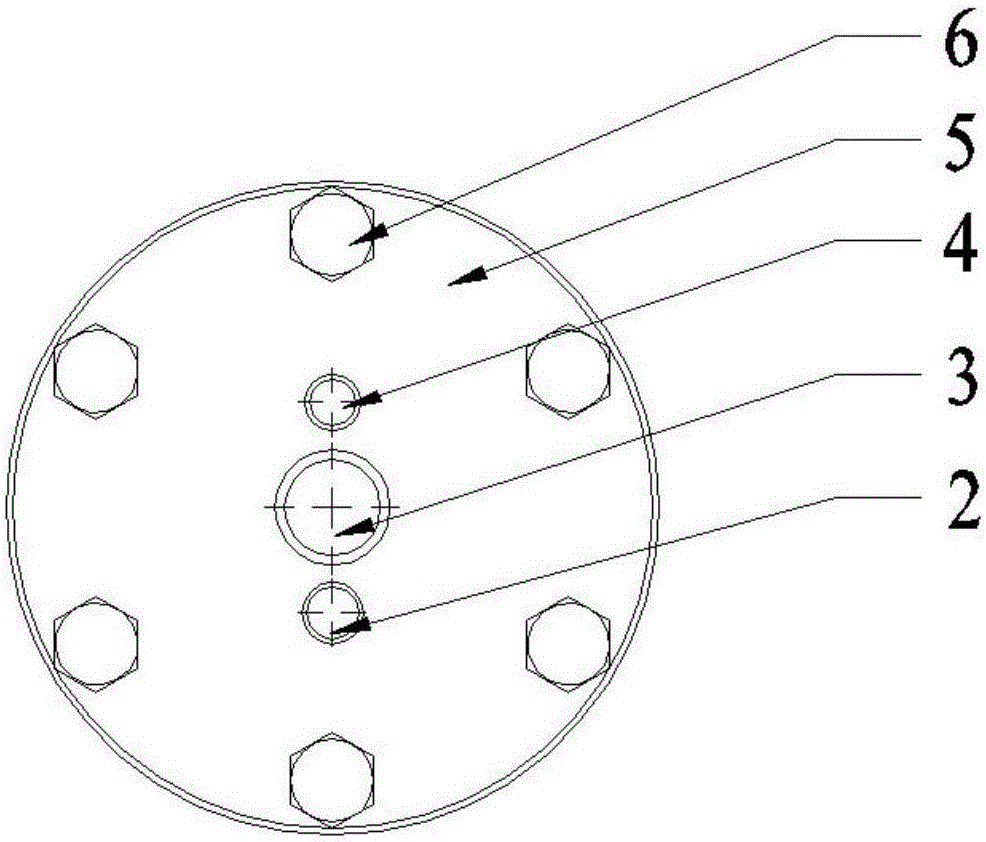

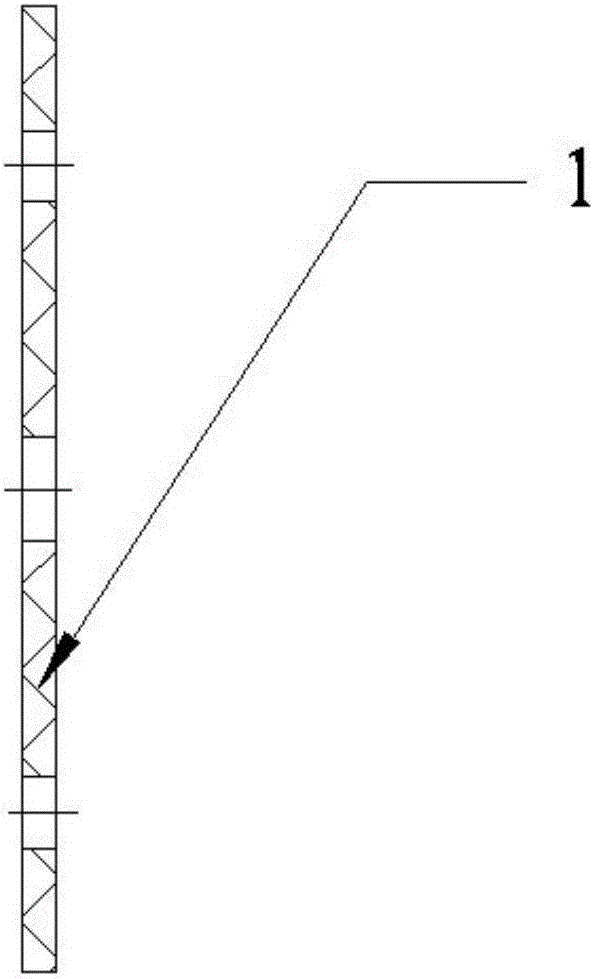

[0037] like Figure 1-6 As shown, a device that uses microwaves to increase the gas energy of a light gas gun includes a first coating 1, a microwave source 3, a flange 5, a structural layer 8, a second coating 9, an inflation interface 11, a coating base 12, The wave-absorbing layer 13 and the deflation interface 14; the structural layer 8 adopts a hollow cylinder structure, and one end of the structural layer 8 is fixedly connected with the flange 5, and the first coating 1 for heat preservation is pasted on the flange 5, and the flange Both the plate 5 and the first coating 1 are provided with holes for installing the microwave source 3, the inner side of the structural layer 8 is transitionally matched with one side of the second coating 9, and the other side of the second coating 9 is glued to the side of the coating layer 12. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com