A combination support reinforcement system and installation and construction method of stiff concrete inclined wall formwork

A formwork support and concrete technology, which is applied to the connection of formwork/formwork/work frame, the preparation of building components on site, and construction, etc., can solve the problem of no operating space, large one-time rental of steel pipe fasteners, affecting construction period, etc. problems, to achieve the effect of simple construction process operation, simple structure design, and reduced amortization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

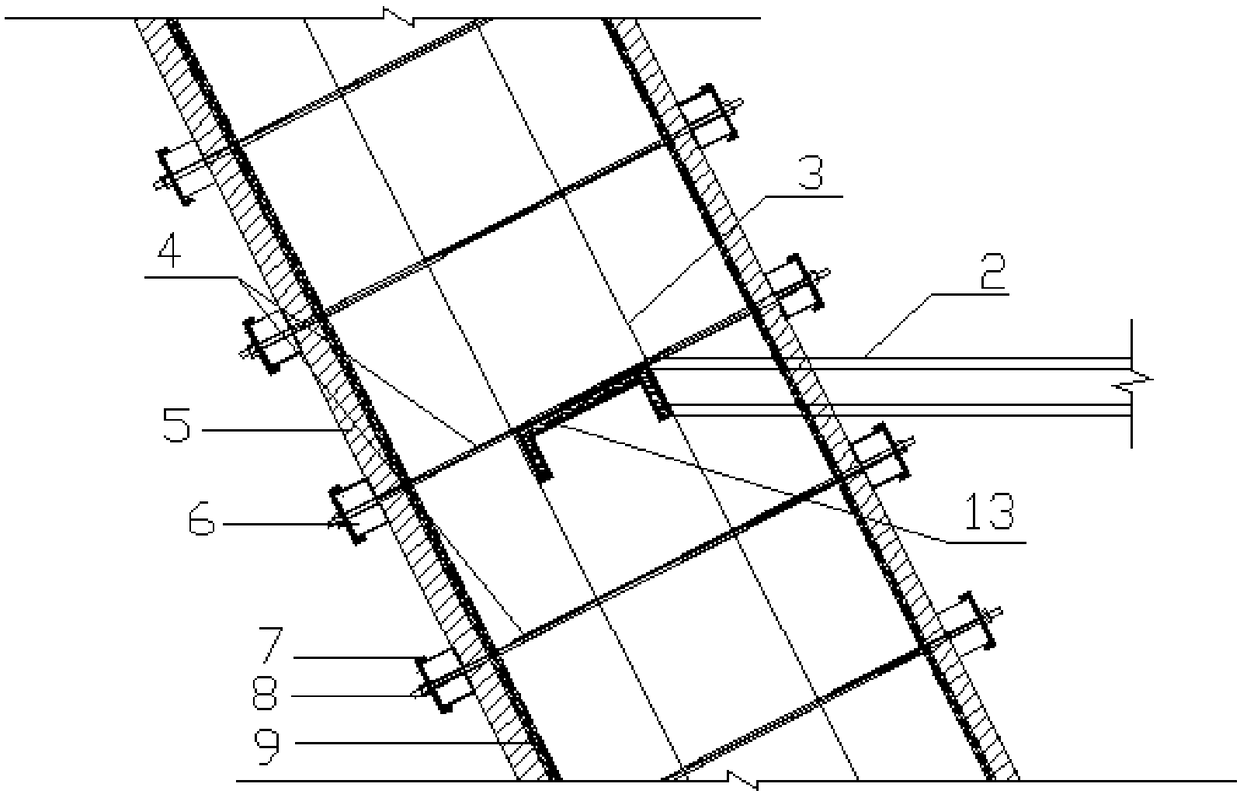

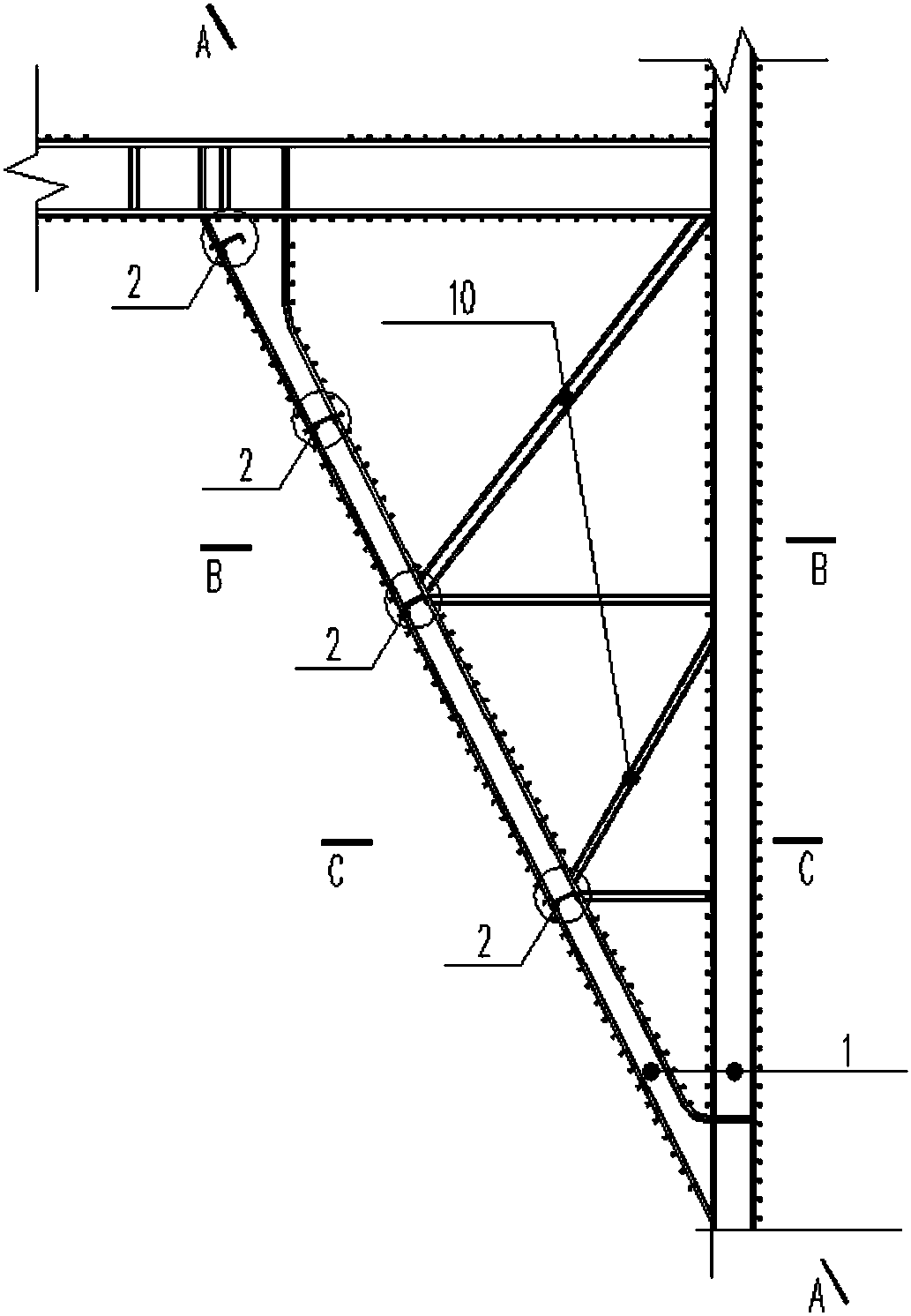

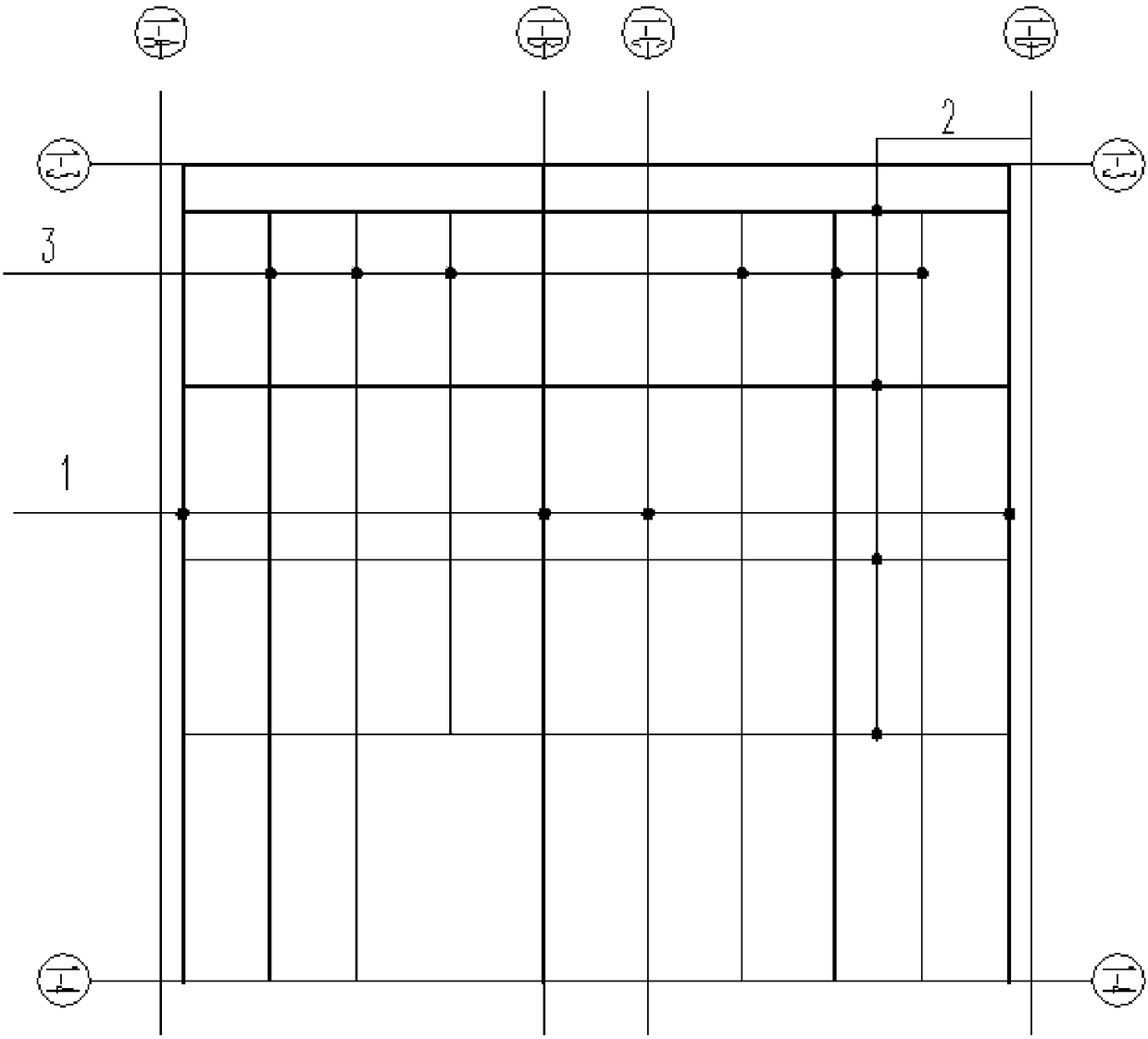

[0031] like figure 1 and Figure 2-1 As shown, a stiff concrete inclined shear wall formwork support and reinforcement system includes a vertical shear wall and an inclined shear wall connected to the vertical shear wall and inclined upward relative to the vertical shear wall. The vertical shear wall and the inclined shear wall are provided with a main steel frame 1 built into the outline of the wall, and the outside of the main steel frame is provided with a formwork 9, and the outside of the formwork is provided with a horizontal main flute 6 for supporting and reinforcing the formwork and the vertical secondary flute 5, the horizontal main flute 6 is perpendicular to the vertical secondary flute 5, the main steel frame 1 is welded with a pull screw 4, and the two ends of the pull screw pass through the template 9 and The horizontal main flute and the vertical secondary flute are integrally fixed with the formwork. The inclined shear wall is provided with a vertical steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com