Preset slurry grouting sleeve for building, prefabricated member connecting structure and prefabricated member connecting method

A kind of grouting material and technology for construction, which is applied in the direction of building components, building reinforcements, building structures, etc. It can solve the problems that the grouting effect or quality cannot be effectively detected, the assembly rate of prefabricated buildings is affected, and the sleeve and the steel bar are not easy to connect. , to achieve the effect of overcoming the large dispersion of grouting quality, reducing the material of grouting pipe and grouting pipe, and stabilizing the quality of grout with precise ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

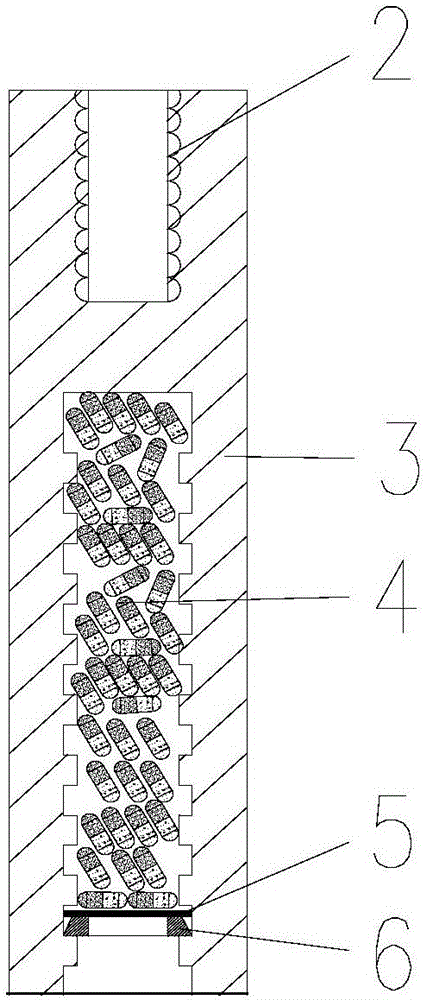

[0039] A kind of preset grouting material sleeve for construction, such as figure 1 As shown, it includes a sleeve body 3, the upper part of the sleeve body 3 has a threaded connection hole 2 for threaded connection with the upper steel bar 1, the sleeve body 3 has a slurry cavity, and the slurry cavity is provided with multiple A slurry bag 4, the slurry bag 4 is packaged in the slurry chamber by a sealed tin foil 5, in order to ensure that the sealed tin foil 5 is damaged during transportation, a protective rubber plug 6 is installed at the bottom of the sleeve body 3, and the preferred rubber plug is Perforated rubber stopper.

[0040] The slurry capsule 4 includes at least two types of slurry capsules. The slurry in each capsule does not coagulate, but at least two slurry capsules are mixed together with the slurry that is crushed and ruptured by the lower steel bars to form a coagulable capsule. After various kinds of slurry are mixed together and solidified, the upper s...

Embodiment 2

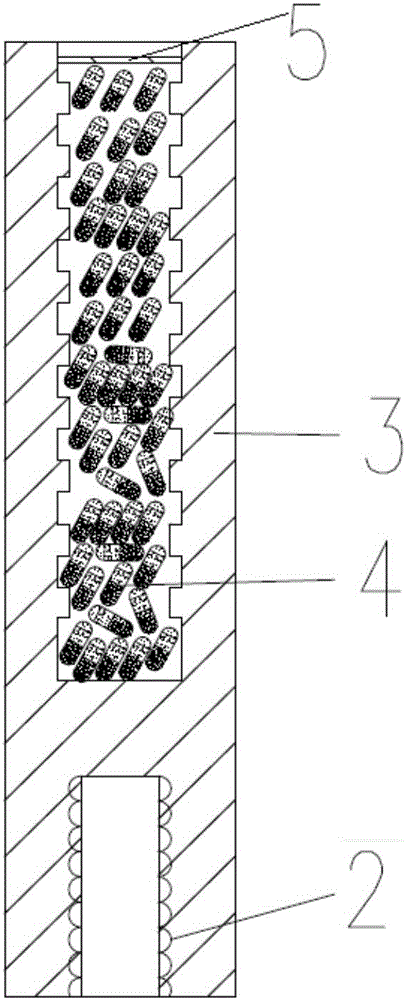

[0046] A kind of preset grouting material sleeve for construction, such as image 3 As shown, the sleeve body 3 is included, the bottom of the sleeve body 3 has a threaded connection hole 2 for threaded connection with the lower steel bar 7, the sleeve body 3 has a slurry cavity, and the slurry cavity is provided with multiple A slurry bag 4, the slurry bag 4 is packaged in the slurry cavity by a sealed tin foil 5.

[0047] The slurry capsule 4 includes at least two types of slurry capsules, the slurry in each capsule does not coagulate, but at least two slurry capsules are mixed together with the slurry crushed and broken by the upper steel bar to form a condensable capsule. After various kinds of slurry are mixed together and solidified, the upper steel bar and the lower steel bar are fixedly connected together.

[0048] The slurry bladder 4 is preferably a double slurry bladder.

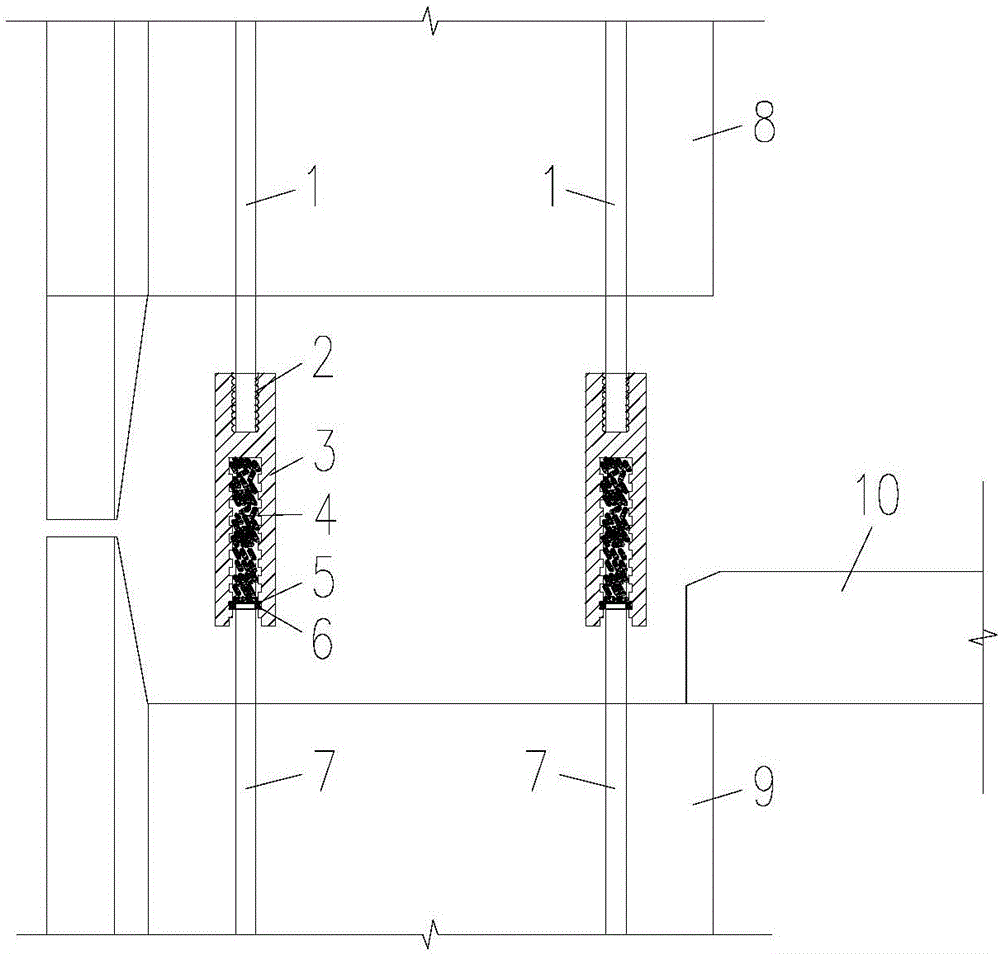

[0049] A prefabricated connection structure, such as Figure 4 As shown, it includes an upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com