A method for combination tanning with less chromium after immersion of compound enzyme preparation

A compound enzyme preparation, combined with tanning technology, is applied in chemical treatment before tanning, small raw hide/large hide/leather/fur treatment, tanning treatment, etc. Scavenging, reducing the effect of chromium salt consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The used technological process of the present invention is as shown in table 1, and the specific operation steps of each operation of the tanning workshop section of tanning process and materials used are as follows:

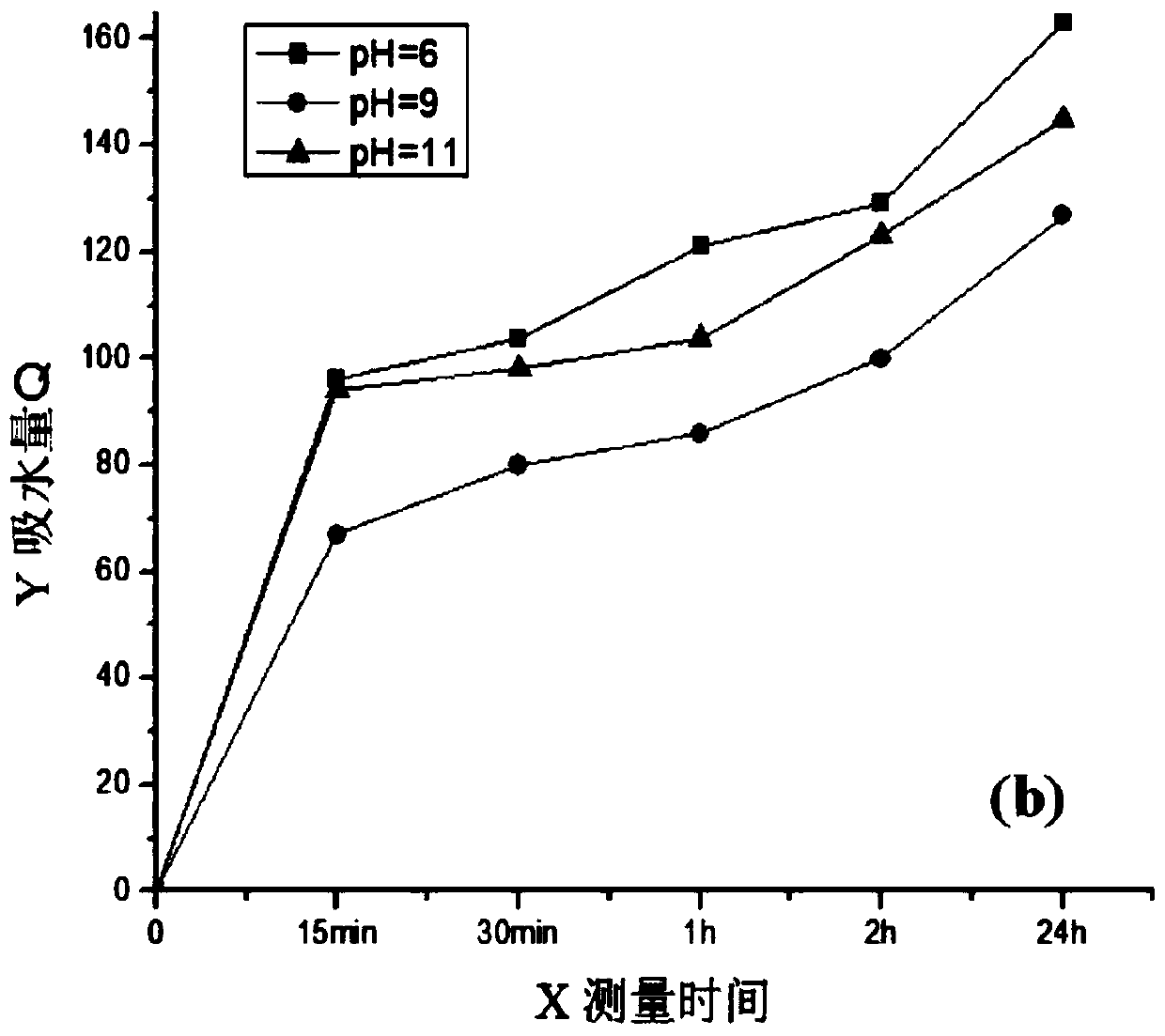

[0036] (1) Soaking in water: in the drum, water: 200%; temperature: 25°C; add water from the drum door, compound protease (alkaline protease: neutral lipase = 5:1), cowhide, rotate for 60 minutes, stop for 20 minutes, Turn for 20 minutes, stop for 50 minutes, first turn for 40 minutes in the first 2 hours, stop for 20 minutes (second time), turn for 20 minutes in the next 2 hours, stop for 40 minutes (second time), and then carry out subsequent conventional hair removal and liming processes.

[0037] (2) Pre-tanning: carry out in the drum, the liquid ratio is 1, add 4-8wt% of zinc sulfate, 1% of sodium citrate, and the tanning temperature is 30°C. Turn for 6 hours, stop for 5 minutes every 1 hour, and stop the drum overnight.

[0038] (3) Pickling: carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com