Production method of high-concentration and high-quality rice vinegar

A production method and high-concentration technology, applied in the production field of high-concentration and high-quality rice vinegar, to achieve the effect of efficiently dissolving oxygen, improving product quality and stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

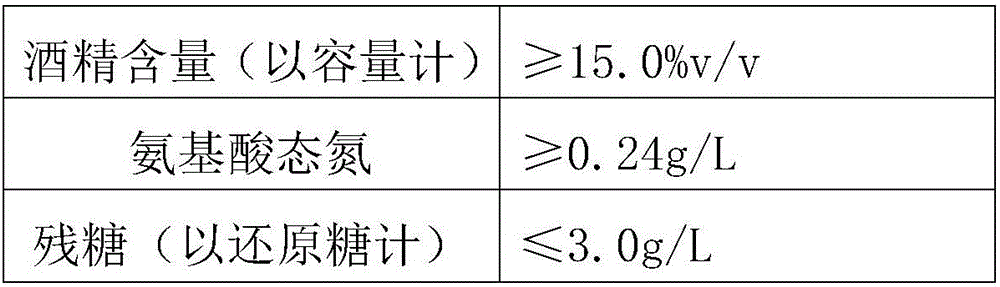

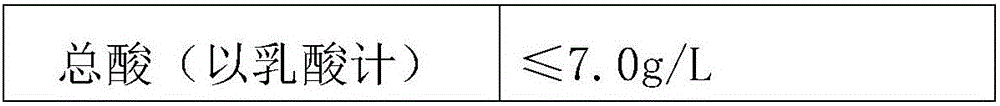

[0061] Take 500kg of rice, remove impurities, and then pulverize it with a grinder. The fineness needs to be 50-60 mesh. Put the rice flour into the rice slurry pool, add 1250kg of water, mix well, pump it into the slurry mixing tank, turn on the agitator, and proceed according to the process flow Slurry mixing and liquefaction; after liquefaction is completed, pump into the alcohol fermenter to cool down. When the temperature drops to 26-28°C, add 2kg of compound brewing koji to carry out alcohol fermentation. After 10 days of fermentation, carry out alcohol detection; if the alcohol content is greater than 15.0 %v / v, press filtration can be carried out, and then acetic acid fermentation is carried out according to the process flow, and the fermentation temperature, acidity and alcohol content in the acetic acid fermentation tank are monitored; if the alcohol content of vinegar mash in the acetic acid fermentation tank is lower than 0.3% v / v, Release 40% of the total volume of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com