Leather product edge sealing agent and edge sealing method

An edge sealing agent and leather goods technology, applied in leather, household appliances, applications, etc., can solve the problems of difficult edge imprinting, complicated edge coating process, low work efficiency, etc., and achieve increased toughness, fast edge sealing, and effective smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

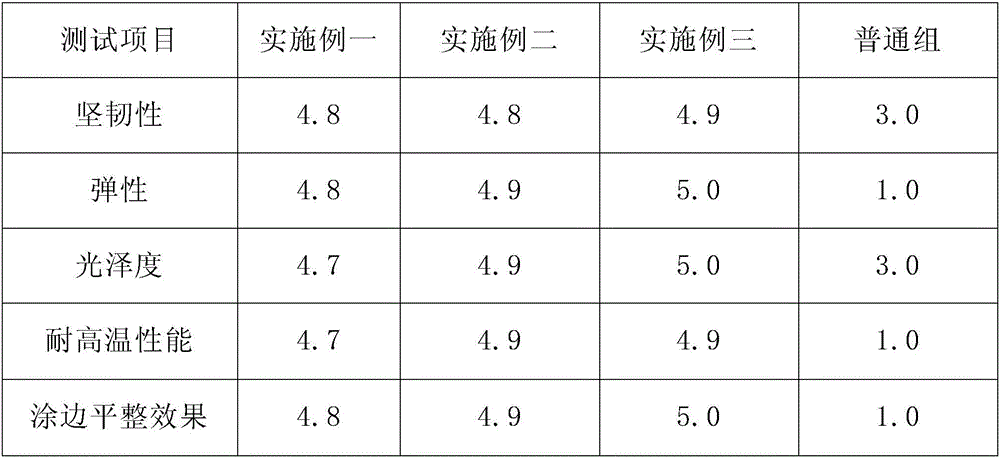

Examples

preparation example Construction

[0036] The preparation method of this edge sealing coating comprises the following steps:

[0037] Step 1: Add high-solid polyurethane resin into the reactor, which is a stainless steel reactor, and turn on the stirring device of the reactor;

[0038] Step 2: Slowly add the high temperature resistant slip additive into the reactor, adjust the rotation speed of the stirring device of the reactor to 700 revolutions per minute, and adjust the temperature inside the reactor to 20°C;

[0039] Step 3: Add the defoamer dropwise to the inside of the reactor, and the dropping tool is a dropper, adjust the speed of the stirring device of the reactor to 700 revolutions per minute, and adjust the temperature inside the reactor to 20°C;

[0040] Step 4: Add the leveling agent dropwise to the inside of the reactor. The dripping tool is a dropper. Adjust the rotation speed of the stirring device of the reactor to 700 revolutions per minute, and adjust the temperature inside the reactor to 20...

Embodiment 1

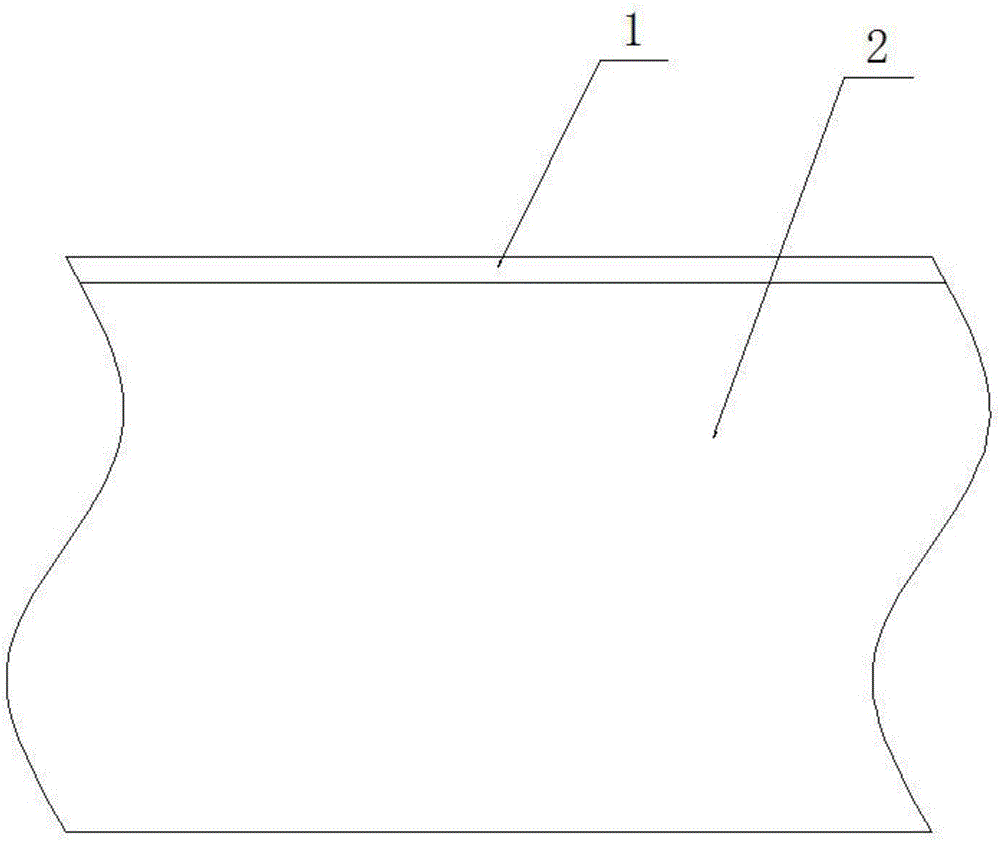

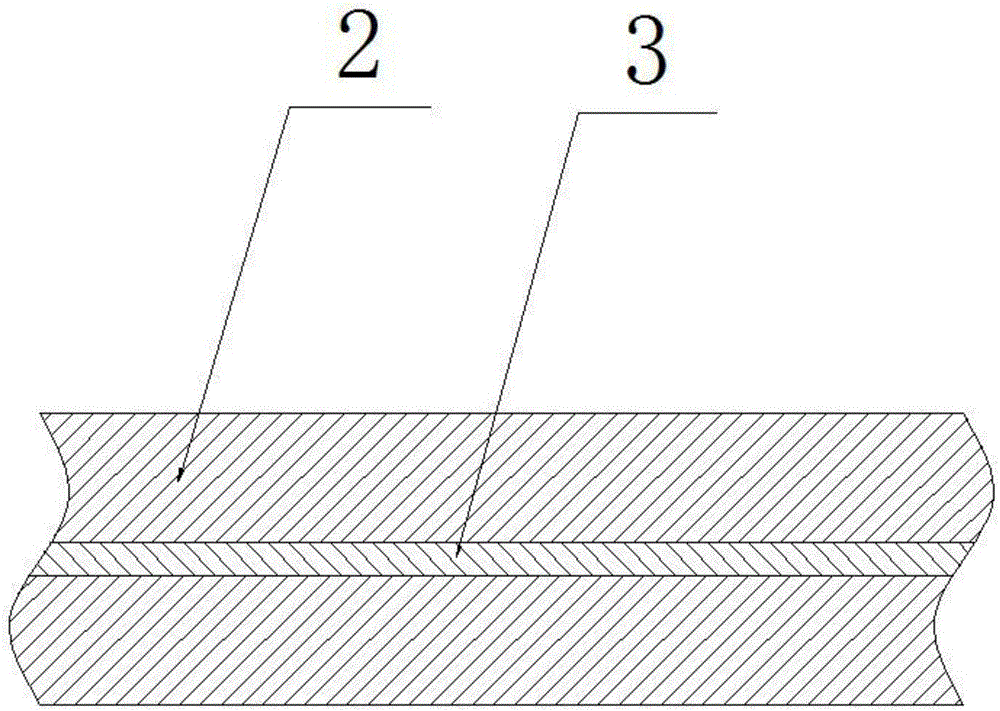

[0044] Embodiment 1: a kind of edge sealing agent for leather goods, including two leather layers 2 and an extruded layer 3, an extruded layer 3 is arranged between the two leather layers 2, and the extruded layer 3 and the leather layer 2 are connected by glue , the top of the leather layer 2 is provided with an edge-banding layer 1, and the shape of the edge-banding layer 1 is arc-shaped.

[0045] The material of the edge-sealing layer 1 is high-solid polyurethane resin, high-temperature slippery additive, leveling agent, defoamer, association aid and anti-drying film additive, wherein the content of high-solid polyurethane resin 75%, high temperature resistant slip additive 8%, leveling agent 1.5%, defoamer 0.5%, association aid 4% and anti-dry film additive 6%.

[0046] The method includes the following steps:

[0047] Step 1: Put the raw materials into the edge coating box and adjust the gap between the edge coating boxes;

[0048] Step 2: Put the leather goods on the e...

Embodiment 2

[0059] Embodiment 2: Kind leather edge banding agent, including two leather layers 2 and an extruded layer 3, an extruded layer 3 is arranged between the two leather layers 2, and the extruded layer 3 and the leather layer 2 are connected by glue , the top of the leather layer 2 is provided with an edge-banding layer 1, and the shape of the edge-banding layer 1 is arc-shaped.

[0060] The material of the edge-sealing layer 1 is high-solid polyurethane resin, high-temperature slippery additive, leveling agent, defoamer, association aid and anti-drying film additive, wherein the content of high-solid polyurethane resin 85%, high temperature resistant slip additive 8%, leveling agent 1.5%, defoamer 0.5%, association aid 2% and anti-dry film additive 3%.

[0061] The method includes the following steps:

[0062] Step 1: Put the raw materials into the edge coating box and adjust the gap between the edge coating boxes;

[0063] Step 2: Put the leather goods on the edging box and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com