Method for monitoring marine propulsion shafting bearing vibration failure

A bearing vibration and fault monitoring technology, which is applied to ship components, ship construction, ship design, etc., can solve problems such as unfavorable fault diagnosis, difficult to determine the type of fault, and inconvenient maintenance and repair of shafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

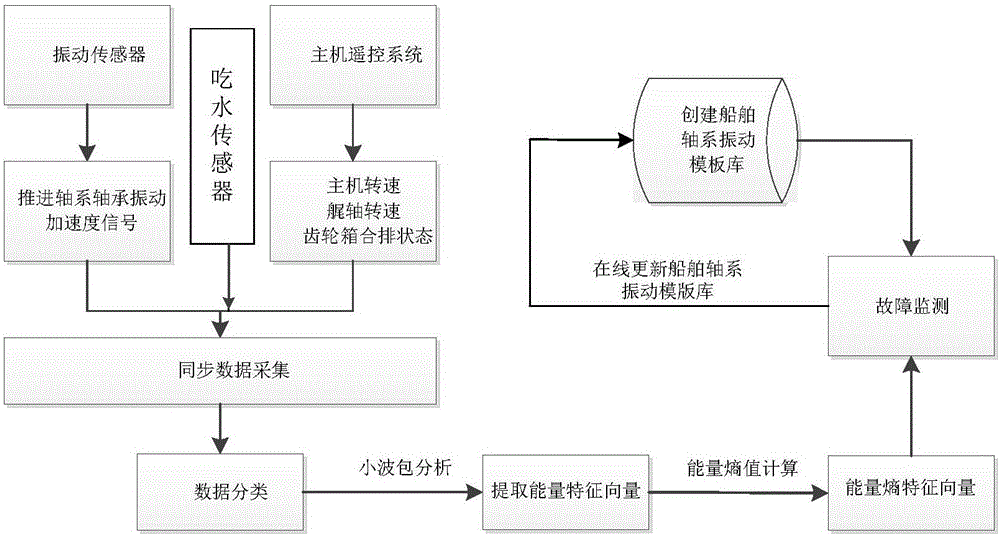

[0039] figure 1 It is a method flow chart of an embodiment of the method for monitoring vibration faults of ship propulsion shafting bearings according to the present invention. The method of this embodiment comprises the following steps:

[0040] (1) Offline creation of the ship propulsion shafting vibration template library: including the energy entropy eigenvectors of each group of bearing vibration signals corresponding to different main engine speeds, stern shaft speeds, and gearbox alignment states under the trouble-free operating conditions of the ship propulsion shafting;

[0041] (2) Synchronous data collection: synchronously collect vibration acceleration signals of ship propulsion shafting bearings, main engine speed, stern shaft speed, and gear box alignment status;

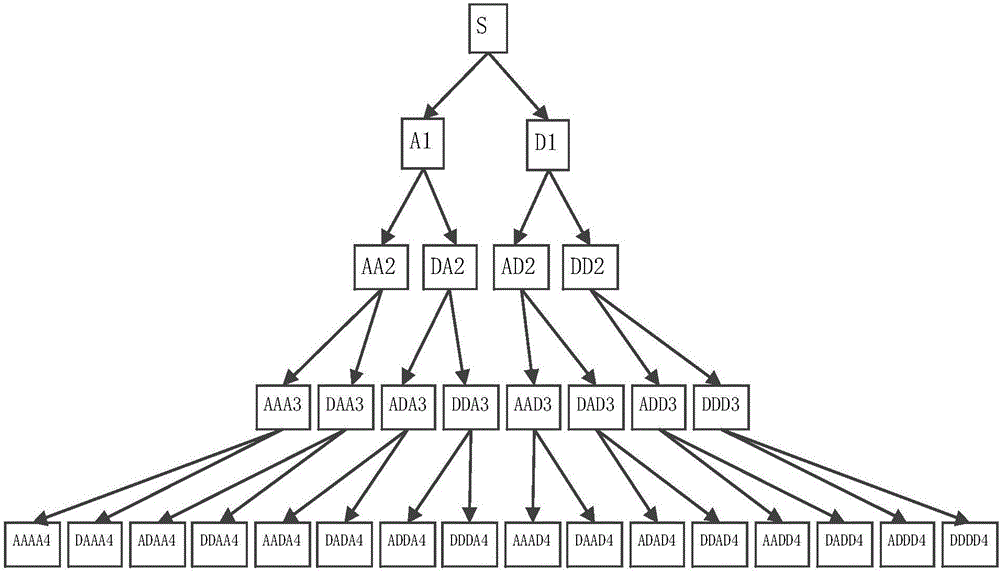

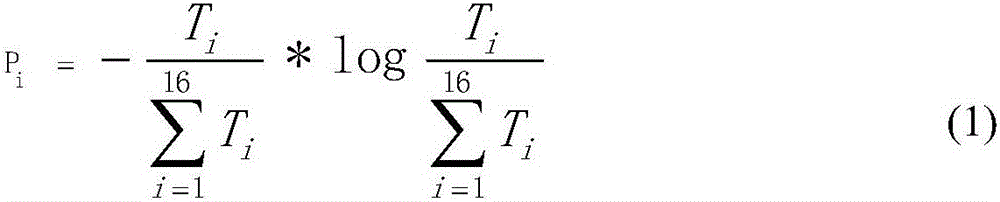

[0042] (3) Data classification: According to the above-mentioned main engine speed, ster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com