Tire antiskid chain

A technology of anti-skid chains and tires, applied in anti-skid devices, tire parts, transportation and packaging, etc., can solve the problems of short service life of tires, falling off and loosening of rubber blocks, etc., to ensure the overall strength, prolong the service life and prevent scratches The effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

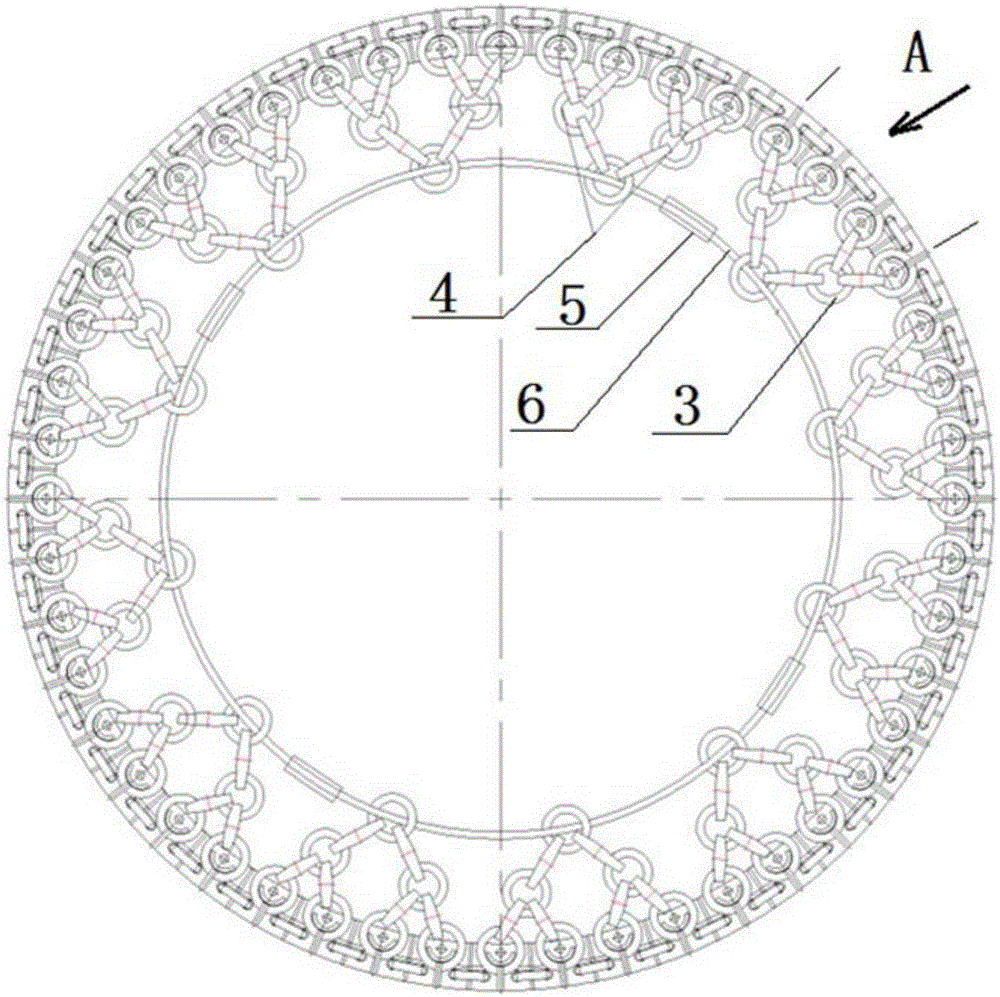

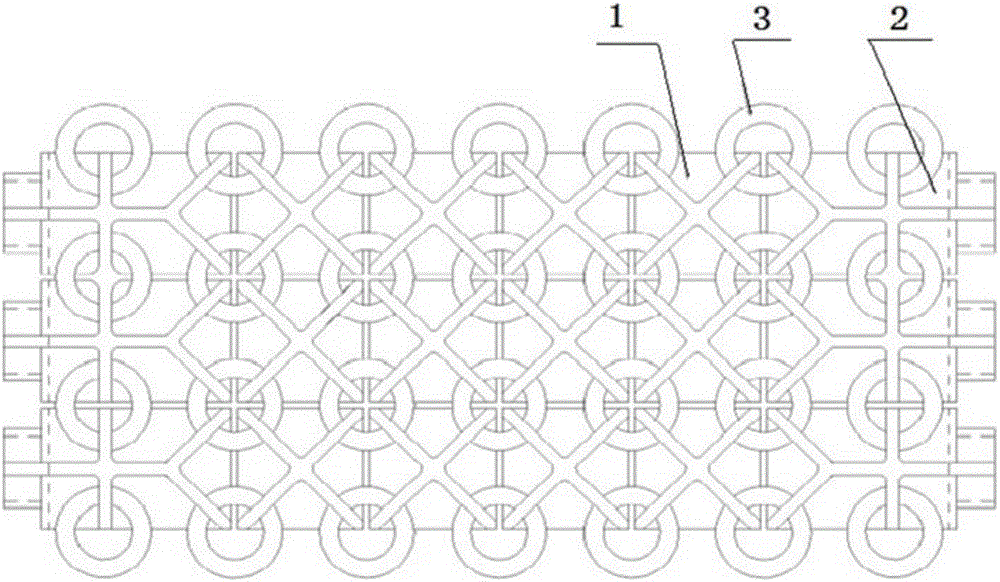

[0023] Such as figure 1 Shown, a kind of tire snow chain, the present invention is characterized in that,

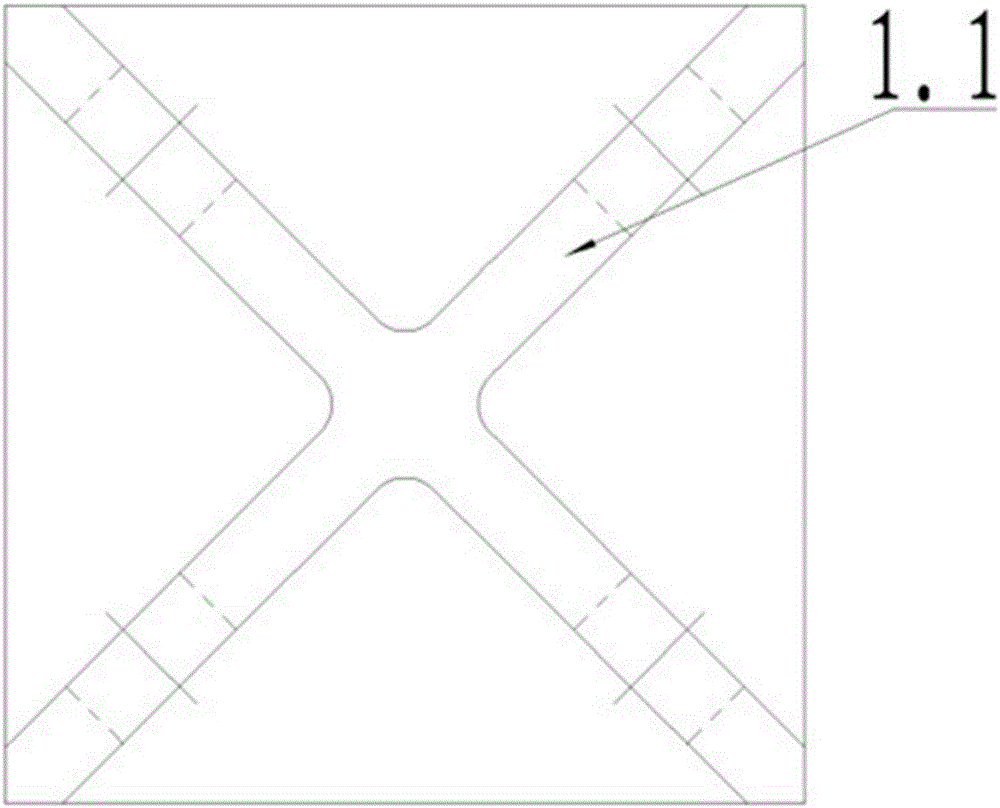

[0024] A tire anti-skid chain, comprising a four-way connecting piece 1, a three-way connecting piece 2, a hanging ear connecting ring 3, a side tension chain 4, and a chain tensioning device 5; wherein, the back of the four-way connecting piece 1 is provided with cross vertical ribs Plate 1.1 and pull connection hole A1.2; the back of the three-way connecting piece 2 is provided with an anti-slip rib plate 2.1 and a pull connection hole B2.2 is opened on the anti-slip vertical rib plate 2.1, and the lug connection ring 3 of the side chain; Using connecting rings 3, several four-way connecting pieces 1 located in the middle and several three-way connecting pieces 2 located on both sides are respectively arranged and connected into a nail-shaped structure capable of multi-directional movement, and wrap the tire tread; the three-way connecting pieces 2 The connecting ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com